Preparation method and application of polystyrene fluorescent microspheres

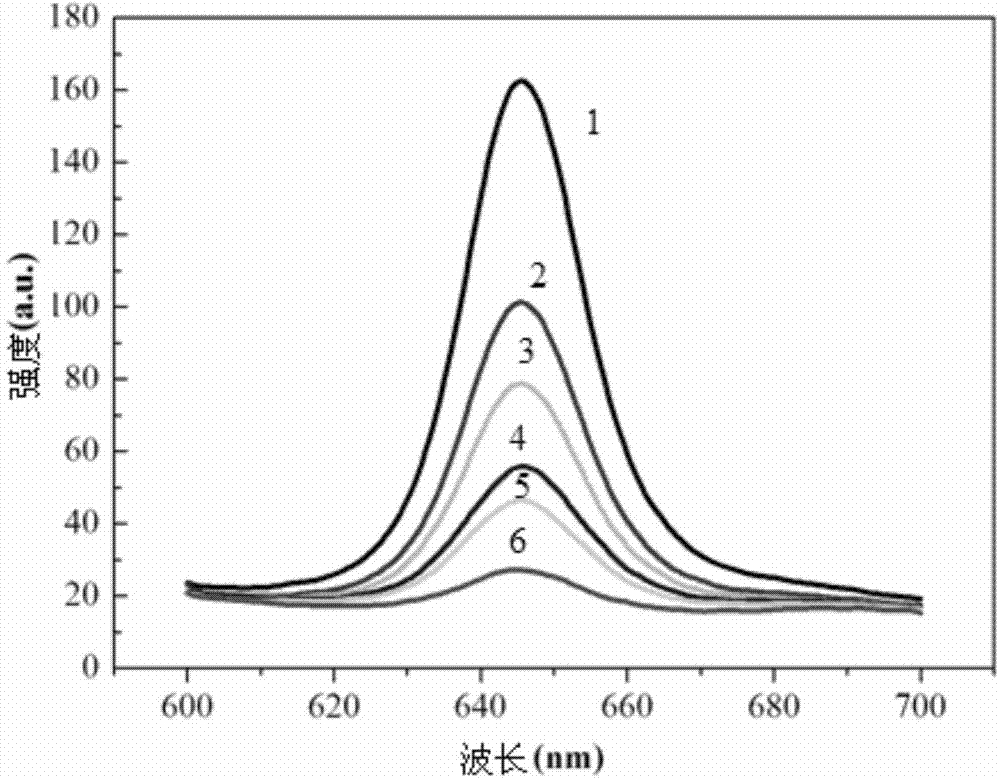

A technology of polystyrene and fluorescent microspheres, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve problems such as poor monodispersity of indicating materials, and achieve easy oxygen sensing testing, good reproducibility, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

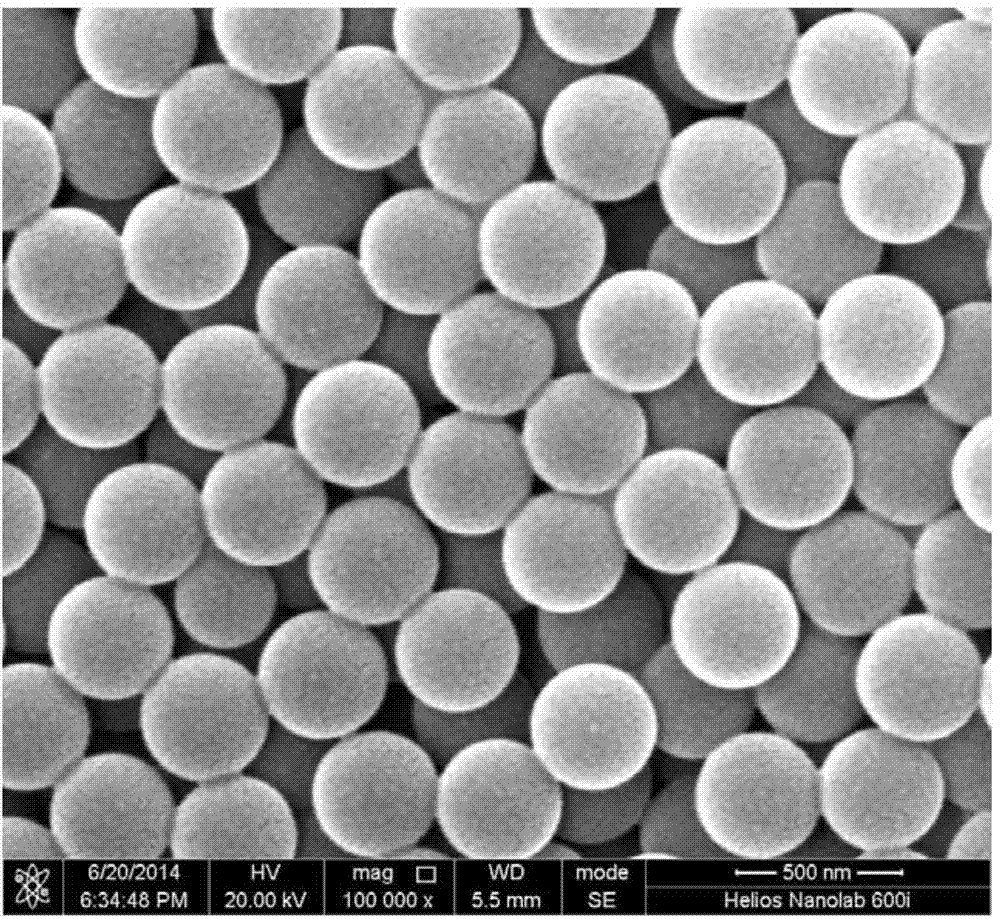

[0023] Specific embodiment one: the preparation method of a kind of polystyrene fluorescent microsphere of present embodiment is carried out according to the following steps:

[0024] Add ultrapure water into the reaction vessel, and mechanically stir for 25min to 35min at a speed of 350r / min to 450r / min under the protection of nitrogen atmosphere, then add fluorescent indicator material and polystyrene, continue to stir for 10min to 20min, then add over Potassium sulfate aqueous solution is condensed and refluxed for 22h-24h at a temperature of 65-75°C to obtain polystyrene fluorescent microspheres;

[0025] The ratio of the mass of the fluorescent indicating material to the volume of polystyrene is (10-40) mg: 3 mL;

[0026] The ratio of the mass of the fluorescent indicator material to the volume of ultrapure water is (10-40) mg: 200 mL;

[0027] The ratio of the mass of the fluorescent indicator material to the volume of the potassium persulfate aqueous solution is (10-40...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment differs from Embodiment 1 in that the ratio of the mass of the fluorescent indicator material to the volume of polystyrene is 20mg:3mL. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the ratio of the mass of the fluorescent indicator material to the volume of ultrapure water is 20mg:200mL. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com