Electromagnetic heating curing and forming device and method for preparing filament wound composite material pipe body by using electromagnetic heating curing and forming device

A technology of winding composite materials and heating and curing, applied in applications, household appliances, tubular objects, etc., can solve the problems of poor heating accuracy and heating uniformity, difficult to obtain heat sources, and low heating efficiency, and achieve high heating reliability and temperature control. High accuracy and heating efficiency, and the effect of improving temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

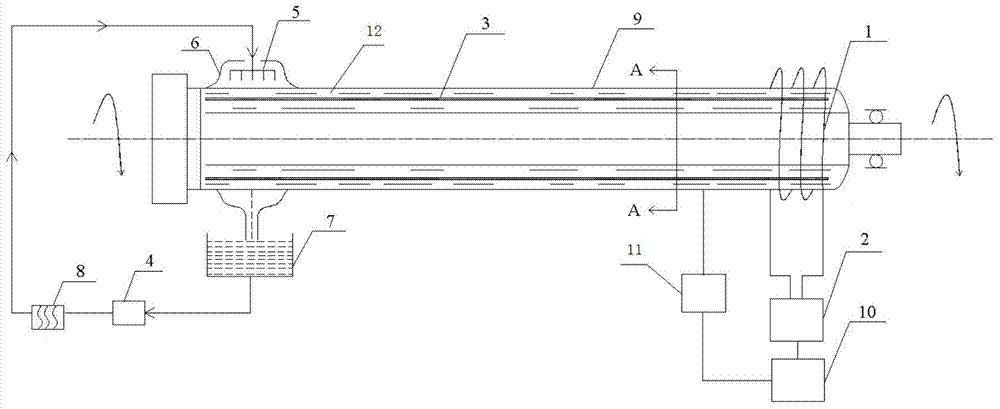

[0029] Specific embodiment 1: This embodiment is an electromagnetic heating solidification molding device, which is characterized in that it includes an electromagnetic heating coil 1, an electromagnetic heating power supply 2, a heat pipe 3, a shower 5, a cooling liquid shield 6, and a cooling liquid tank 7 , water pump 4, radiator 8, mandrel 9, electromagnetic heating controller 10, temperature sensor 11 and heat transfer medium 12;

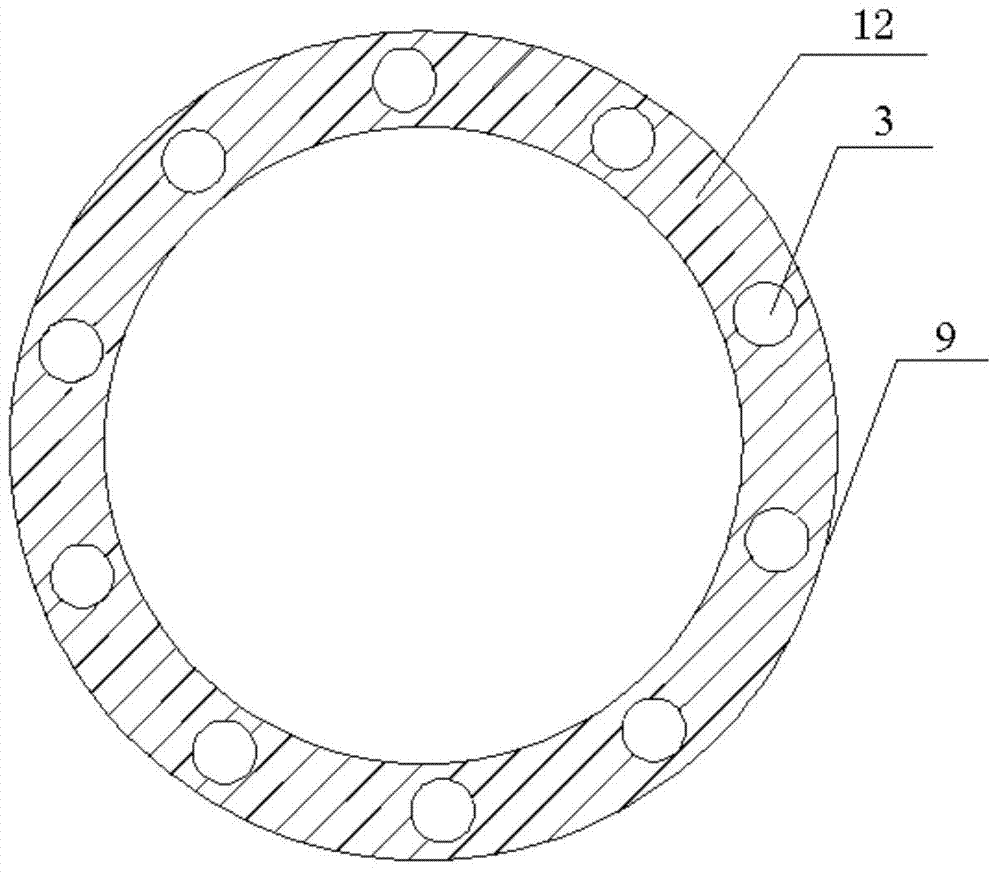

[0030] The mandrel 9 is a sleeve-type structure, an interlayer is formed between the outer wall of the inner tube and the inner wall of the outer tube, the interlayer is filled with a heat-conducting medium 12, and the array of heat pipes 3 is distributed in the heat-conducting medium 12 in the interlayer; the length of the heat pipe 3 and the core The length ratio of the module 9 is (0.8~0.9):1;

[0031] The electromagnetic heating coil 1 is evenly placed outside the tail end of the core mold 9 and does not rotate with the mold. The two ends o...

specific Embodiment approach 2

[0043] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the heat transfer medium 12 is heat transfer oil. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Embodiment 3: The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the distance between the two electromagnetic heating coils 1 is 40 mm to 60 mm. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com