Method and device for improving thickness uniformity of polyamic acid film

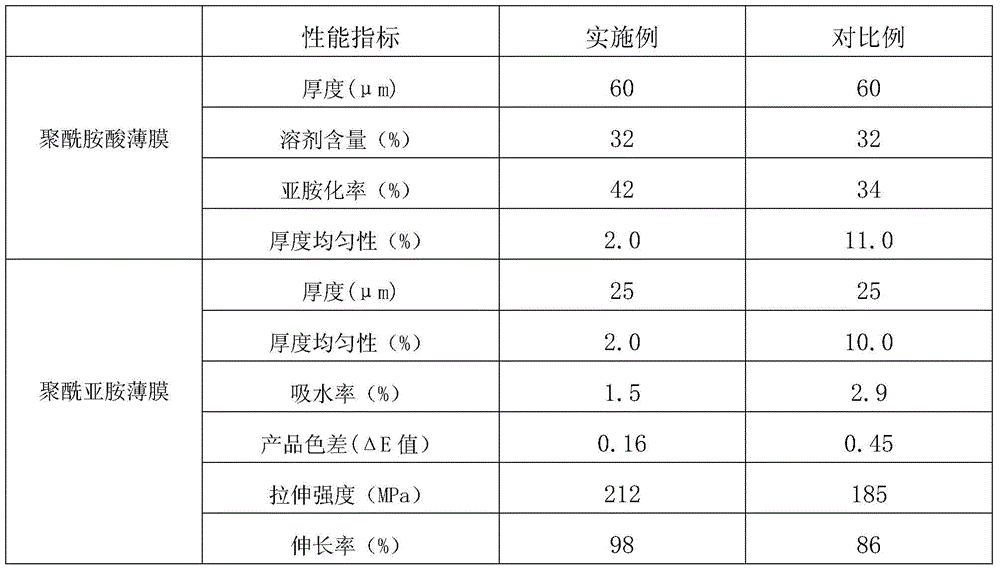

A technology of polyamic acid and film thickness, which is applied in the direction of coating, etc., can solve the problems of difficult maintenance, high investment cost, large thickness tolerance of polyimide film, etc., and achieve improved thickness uniformity and flatness of film rolls , Improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

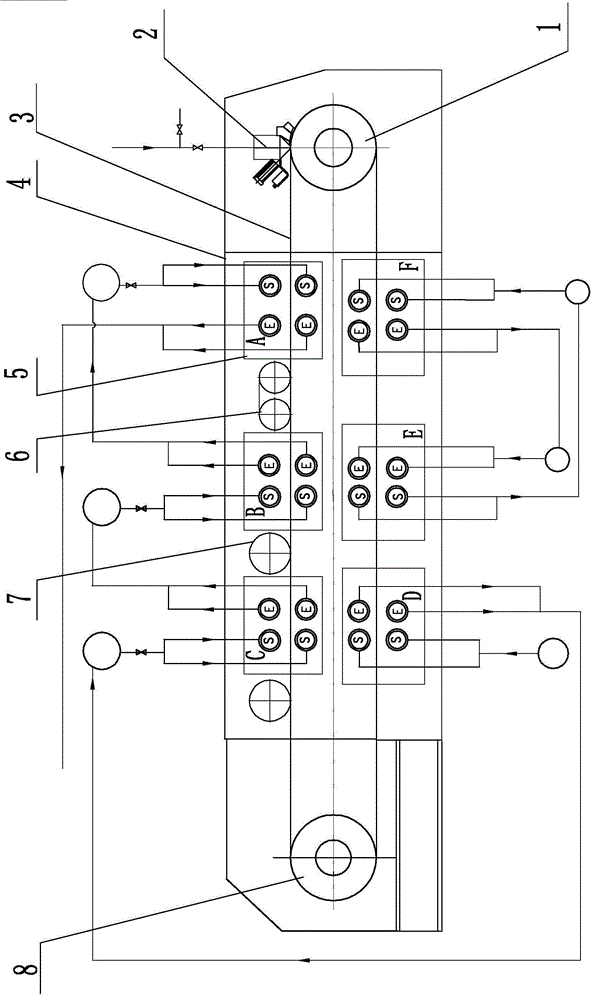

[0025] Examples of the device for improving the uniformity of the thickness of the polyamic acid film figure 1 As shown, it includes a polyamic acid resin solution molding die, a casting steel belt 3, and a casting oven 4. The annular casting steel belt 3 circulates around the front drum 1 and the rear drum 8. The molding die in this example is the extrusion die 2. The lip of the die head 2 is facing the casting steel belt 3 at the highest point of the front drum 1. The casting steel belt 3 passing through the extrusion die 2 carries the polyamic acid resin liquid film into the casting oven 4, in this case, the casting oven 4 There are three static pressure boxes 5 on the upper and lower layers. The casting oven 4 is divided into a preheating zone, a high temperature zone and a cooling zone. Starting from the front drum 1, along the running direction of the casting steel belt 3, such as figure 1 The static pressure boxes 5 shown are respectively called static pressure boxes A t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com