Activated carbon loaded solid super acidic catalyst and preparation method thereof

A technology of solid super acid and activated carbon, which is applied in the fields of refined hydrocarbon oil and petroleum industry, which can solve the problems of high energy consumption and long heating time, and achieve the effects of large specific surface area, high activity at low temperature and strong acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

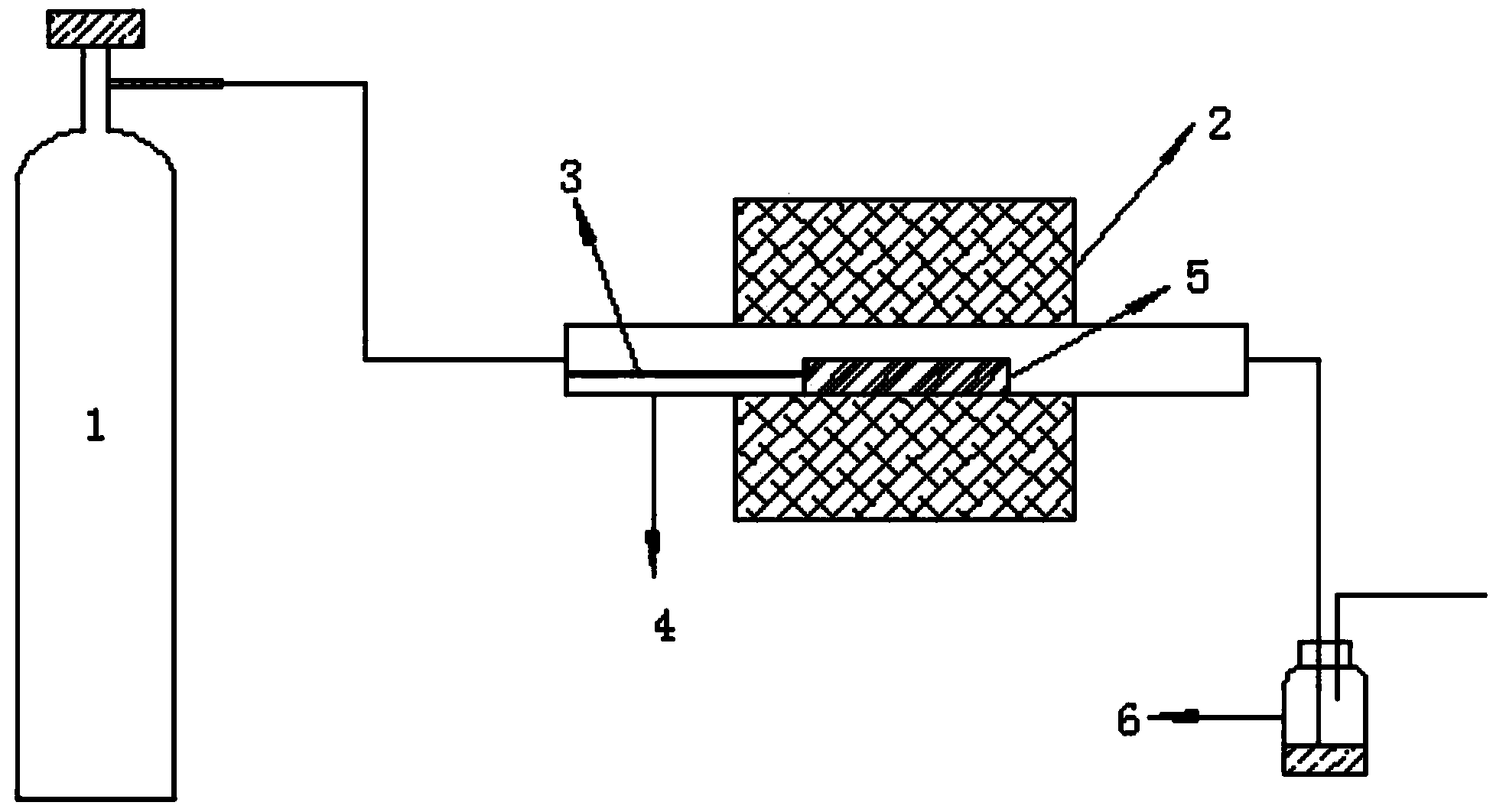

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the above-mentioned activated carbon-supported solid superacid catalyst, the raw material weight percentage components are as follows: activated carbon: 50% ~ 85%, ZrOCl 2 ·8H 2 O: 10% to 30%, (NH 4 ) 2 S 2 o 8 Solution: 5% to 25%; the steps are as follows:

[0031] (1), Grind and sieve the activated carbon to 20-40 mesh, set aside;

[0032] (2), according to ZrOCl 2 ·8H 2 The mass ratio of O to ultrapure water is 5% to 30%, and the ZrOCl 2 ·8H 2 O was dissolved in ultrapure water and placed in an ultrasonic cleaner until ZrOCl 2 ·8H 2 O is completely dissolved;

[0033] Then press activated carbon and ZrOCl 2 ·8H 2 O solution mass ratio is 35%-45%, pour activated carbon into completely dissolved ZrOCl 2 ·8H 2 In the solution of O, after immersing at room temperature for 10-12 hours, add ammonia water to adjust the pH to 9-10 under the condition of magnetic stirring, obtain a precipitate, and age for 10-12 hours; then wash with u...

Embodiment 1

[0038] The preparation method of activated carbon supported solid superacid catalyst comprises the following steps:

[0039] (1), Grind and sieve the activated carbon to 20-40 mesh, set aside;

[0040] (2), according to ZrOCl 2 ·8H 2 The mass ratio of O to ultrapure water is 15%, ZrOCl 2 ·8H 2 O was dissolved in ultrapure water and placed in an ultrasonic cleaner until ZrOCl 2 ·8H 2 O is completely dissolved;

[0041] Then press activated carbon and ZrOCl 2 ·8H 2 O solution mass ratio is 40%, pour activated carbon into completely dissolved ZrOCl 2 ·8H 2 In the solution of O, immerse at room temperature for 10-12 hours, add ammonia water to adjust the pH to 9-10 under the condition of magnetic stirring, obtain a precipitate, age for 10-12 hours, wash with ultra-pure water under the condition of suction filtration, and wash until nothing Cl-so far (with AgNO 3 detection), dried to obtain amorphous Zr(OH) 4 ;

[0042] (3), use 0.5mol L -1 of (NH 4 ) 2 S 2 o 8 Acti...

Embodiment 2

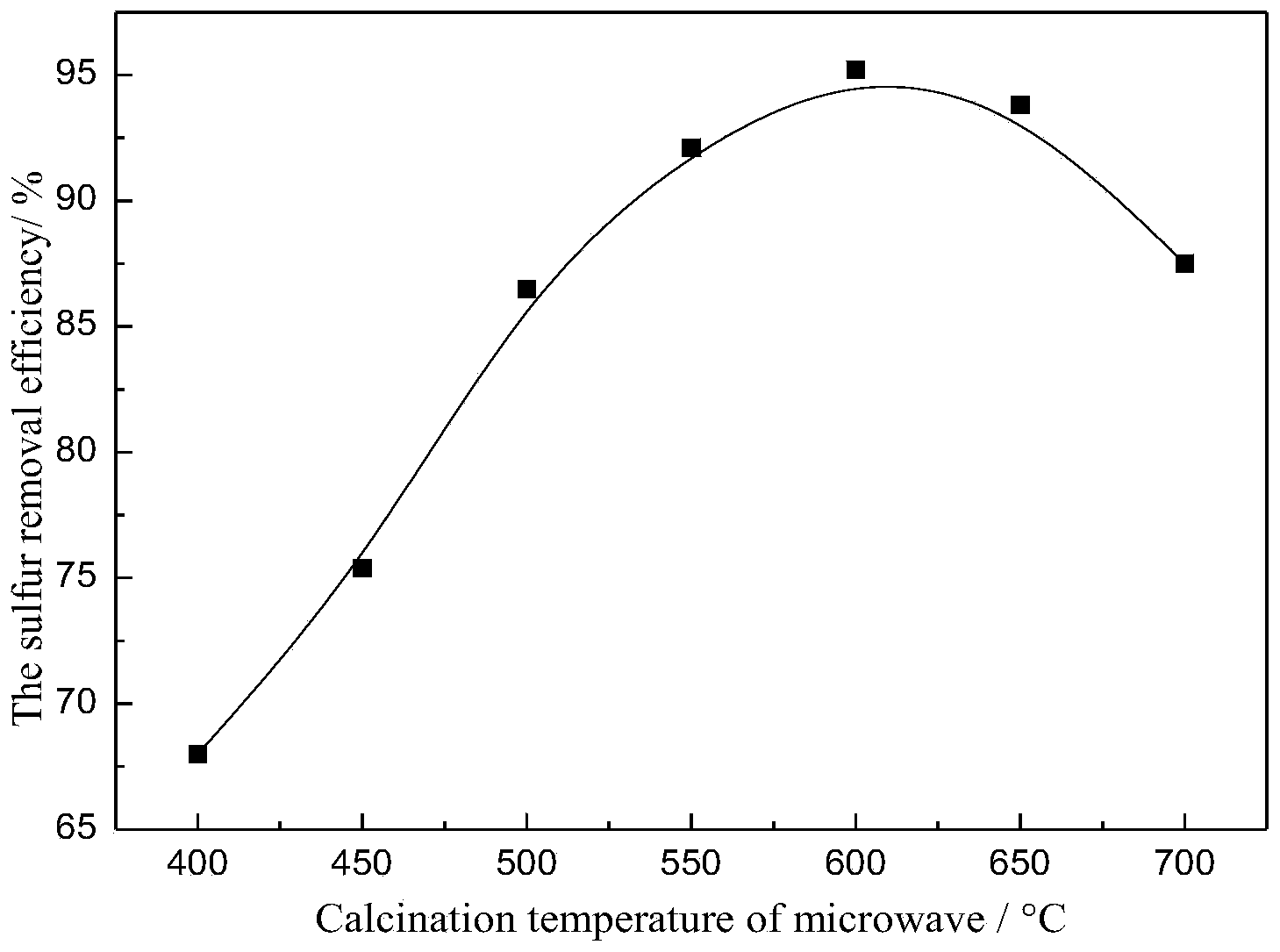

[0046] The difference from Example 1 is: the temperature finally reached by the microwave heating method in step (4) is used as a variable for roasting, and the roasting temperature is 450 ° C;

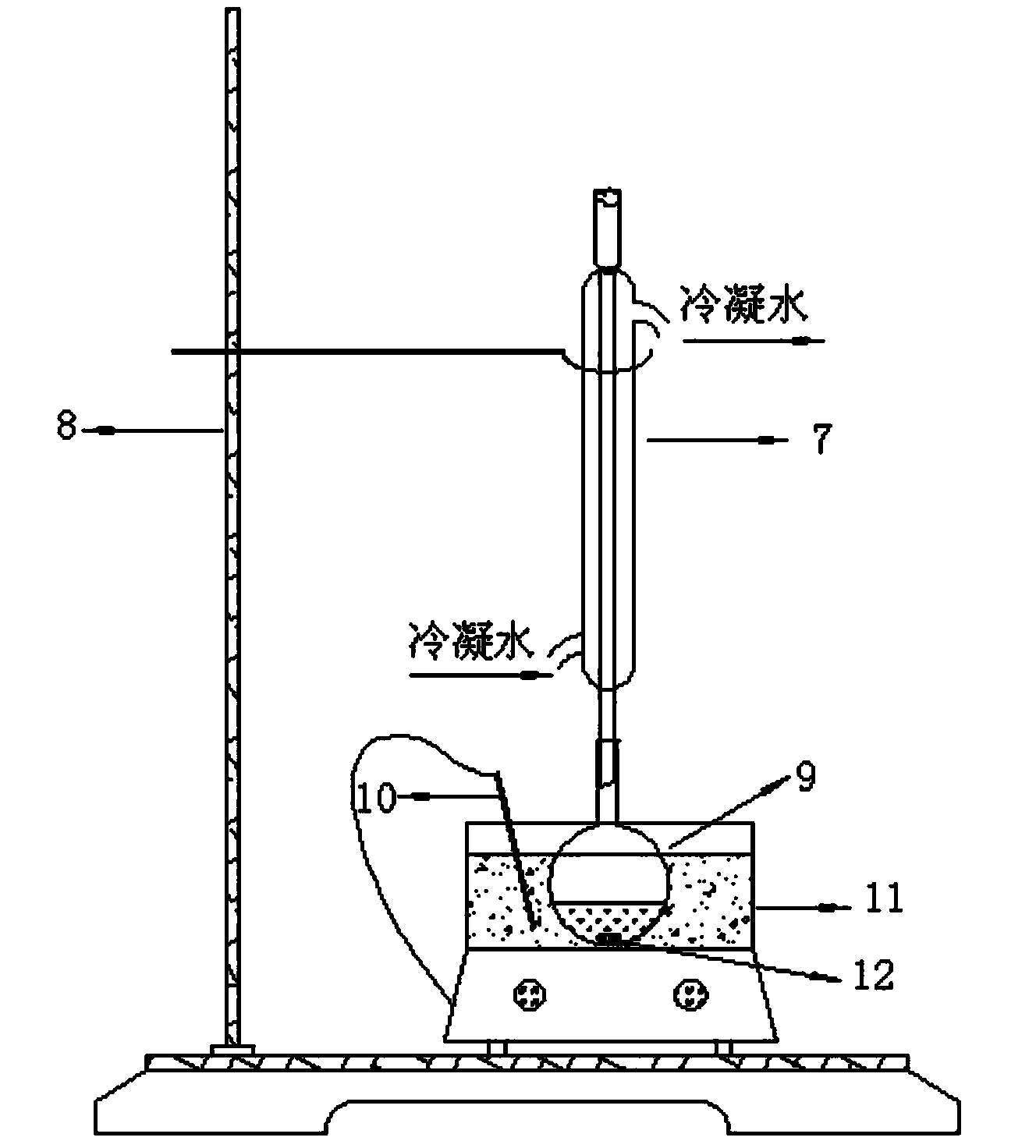

[0047] The catalyst prepared above was used in the oxidative desulfurization experiment, and the oxidative desulfurization device is shown in the attached figure 2 , desulfurization rate see attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com