Composite waterproof layer for underground engineering and its preparation and construction method

A technology of underground engineering and waterproof layer, which is applied in the field of materials, can solve problems such as failure of waterproof system, failure of waterproof system, rupture of waterproof membrane, etc., and achieve the effects of reducing the risk of leakage, prolonging the waterproofing period, and reducing the excavation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Embodiment 1, underground tunnel waterproofing

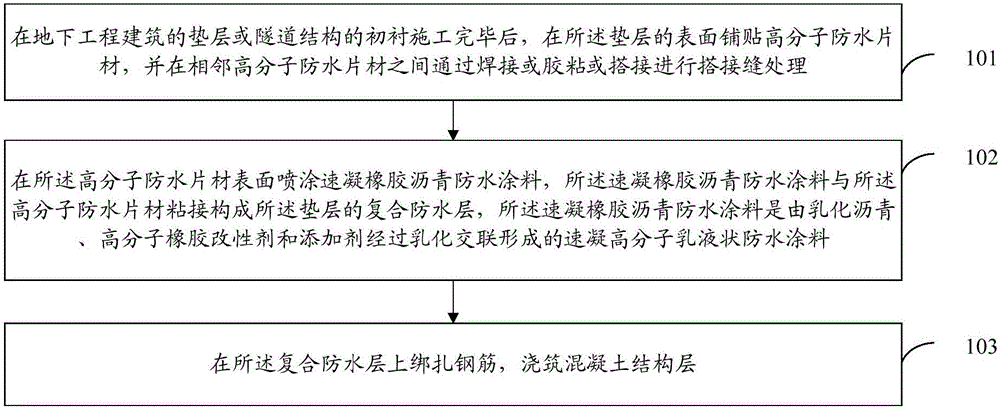

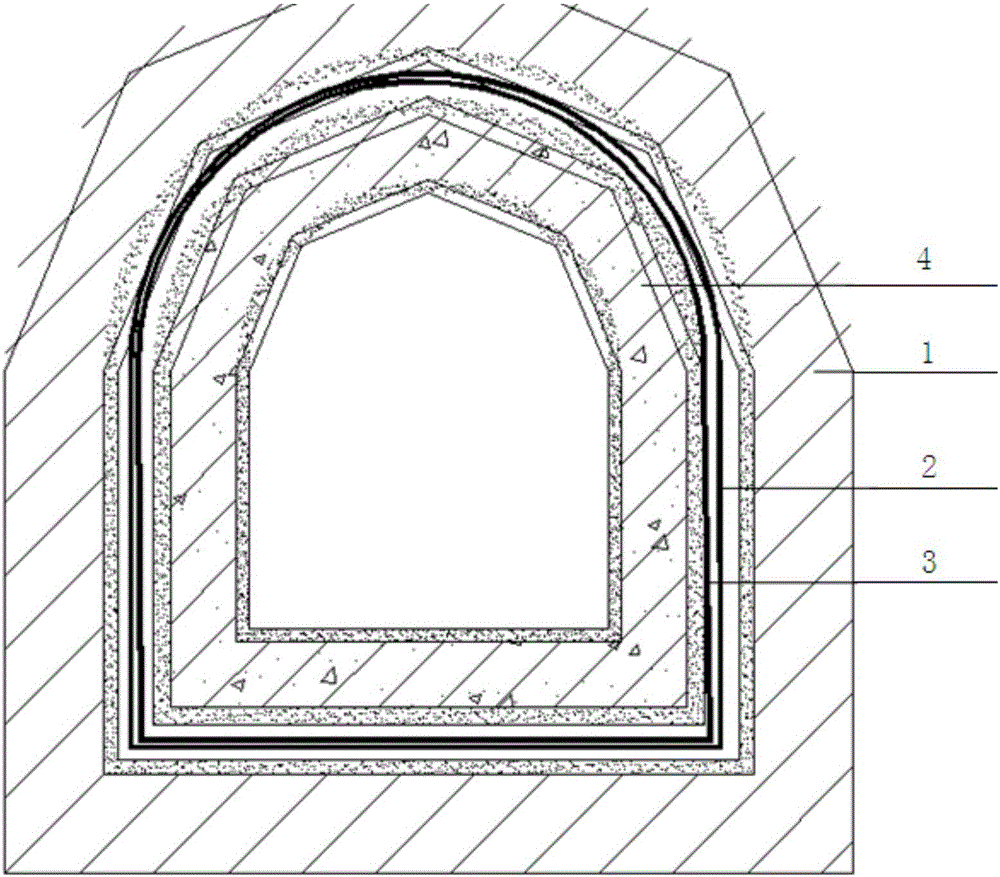

[0087] Such as figure 2 Shown is a schematic diagram of an example of the method for preparing and constructing a composite waterproof layer for environmental engineering according to the present invention. figure 2 Among them, the mark 1 is the concrete supporting layer, the mark 2 is the polymer sheet, the mark 3 is the quick-setting liquid rubber coating, and the mark 4 is the second concrete lining.

[0088] The shotcrete support layer 1 is the tunnel structure cushion (primary lining). After the pouring is completed, the polymer sheet 2 (non-woven fabric, geomembrane) is fixed on the arc-shaped primary lining, and the lap joints are welded or glued. Or directly overlap, and then spray the quick-setting rubber asphalt waterproof coating according to the specified thickness to form the quick-setting liquid rubber coating film 3. After the spraying is completed, directly bind the steel bars and pour the concrete stru...

Embodiment 2

[0089] Embodiment 2, subway open cut station

[0090] After the floor cushion construction is completed, the polymer sheet (HDPE, LDPE, EVA, LLDPE, etc.) is paved, and the lap joints can be glued or welded or directly lapped. After the treatment is completed, spray the quick-setting rubber asphalt waterproof coating. After construction and maintenance are completed, steel bars are directly tied and concrete is poured, thereby omitting the cushion leveling layer and waterproof protection layer, reducing the excavation height, and saving the overall cost. At the same time, non-woven fabrics, geotextiles or polymer sheets can be dry-hanged on the side walls. After hanging, liquid rubber paint is sprayed, and then the concrete structure layer of the side walls is cast. For the waterproof treatment at the junction of the side wall and the bottom plate, it is necessary to pre-spray a long section of waterproof membrane while the waterproof layer of the cushion is being constructed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com