Dicyclopentadiene and carbon fiber cloth composite manhole cover and manufacturing method thereof

A dicyclopentadiene and manufacturing method technology, applied in artificial islands, underwater structures, buildings, etc., can solve the problems of environmental stress cracking resistance, heat resistance, corrosion resistance, poor aging resistance, and unsatisfactory manhole cover strength Long-term use, affecting service life and other issues, to achieve the effect of shortening the processing flow, wide application temperature range and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

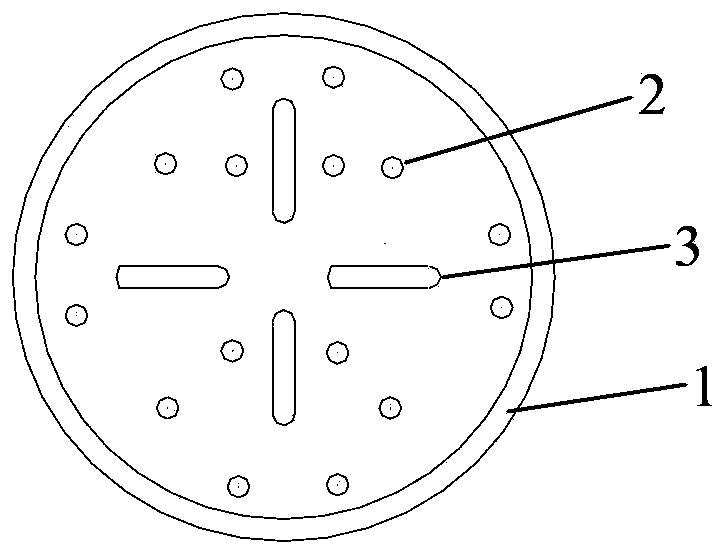

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0021] Reaction injection molding polydicyclopentadiene (referred to as PDCPD-RIM), is to use dicyclopentadiene (referred to as DCPD) extracted from the C5 fraction of petroleum cracking products as raw material, under the action of catalyst and activator, adopt reaction injection molding A new type of engineering material prepared by technology. The Reaction Injection Molding (RIM) process is a molding method for rapidly making complex-shaped plastic products from low-viscosity monomers or oligomers. It integrates polymer polymerization reaction and plastic molding in one step, and has the advantages of fast molding, short cycle, low energy consumption, and good product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com