Method for producing alloyed hot-dip galvanized steel sheet having excellent adhesion to plating and excellent sliding properties

A technology of hot-dip galvanized steel sheet and sliding characteristics, applied in chemical instruments and methods, manufacturing tools, coatings, etc., can solve the problems of inability to stably improve the effect of coating adhesion, and achieve excellent sliding characteristics and coating adhesion. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

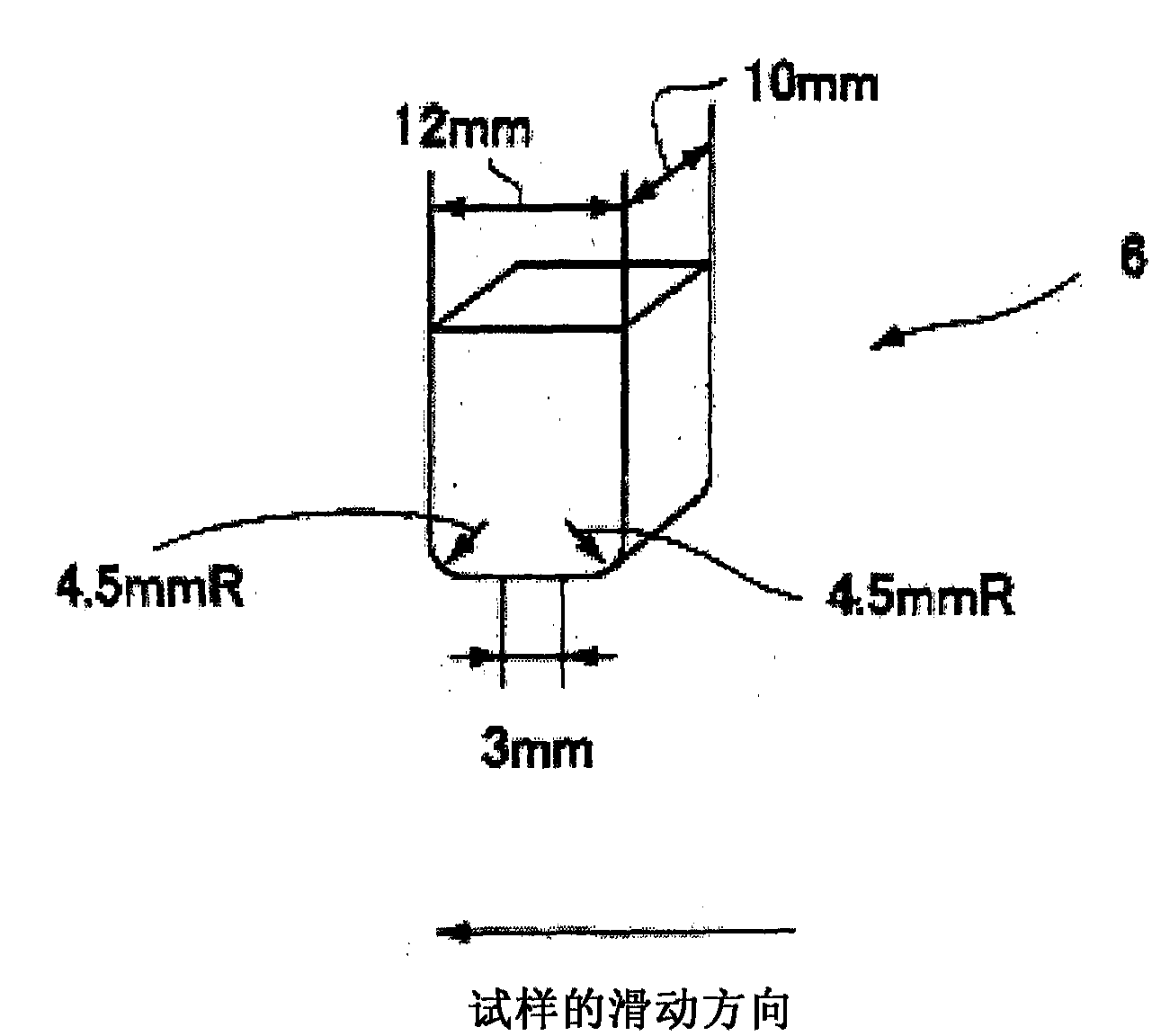

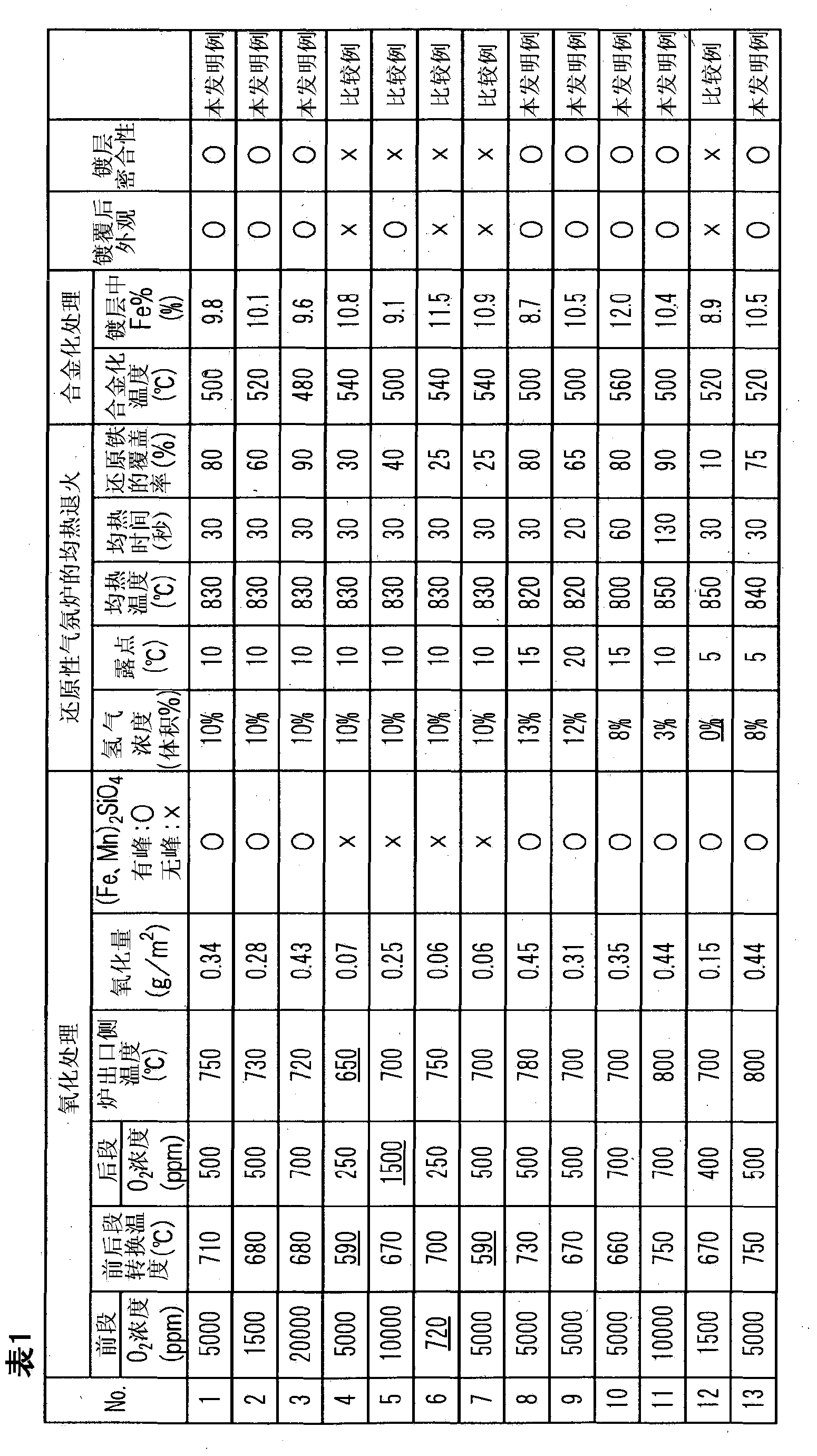

[0057] Steel containing 1.5% by mass of Si was hot-rolled, pickled, and cold-rolled by a known method to manufacture a steel plate with a thickness of 1.5 mm. Other components are C: 0.12% by mass, Mn: 1.9% by mass, Al: 0.04% by mass, S: 0.002% by mass, and P: 0.01% by mass. The obtained steel sheets were oxidized under the conditions shown in Table 1 using a direct-fired heating furnace. Direct fire burners use COG as fuel to adjust the O of the atmosphere by making various changes to the air ratio 2 concentration. The temperature of the steel plate on the furnace exit side was measured using a thermocouple attached to the sample in advance. In addition, the amount of oxidation formed at this time was measured using standard substances and fluorescent X-ray analysis. In addition, Si-containing oxides formed together with iron oxides were analyzed by infrared spectroscopy. According to as (Fe, Mn) 2 SiO 4 Characteristic 980cm -1 Whether there are peaks nearby to judge (...

Embodiment 2

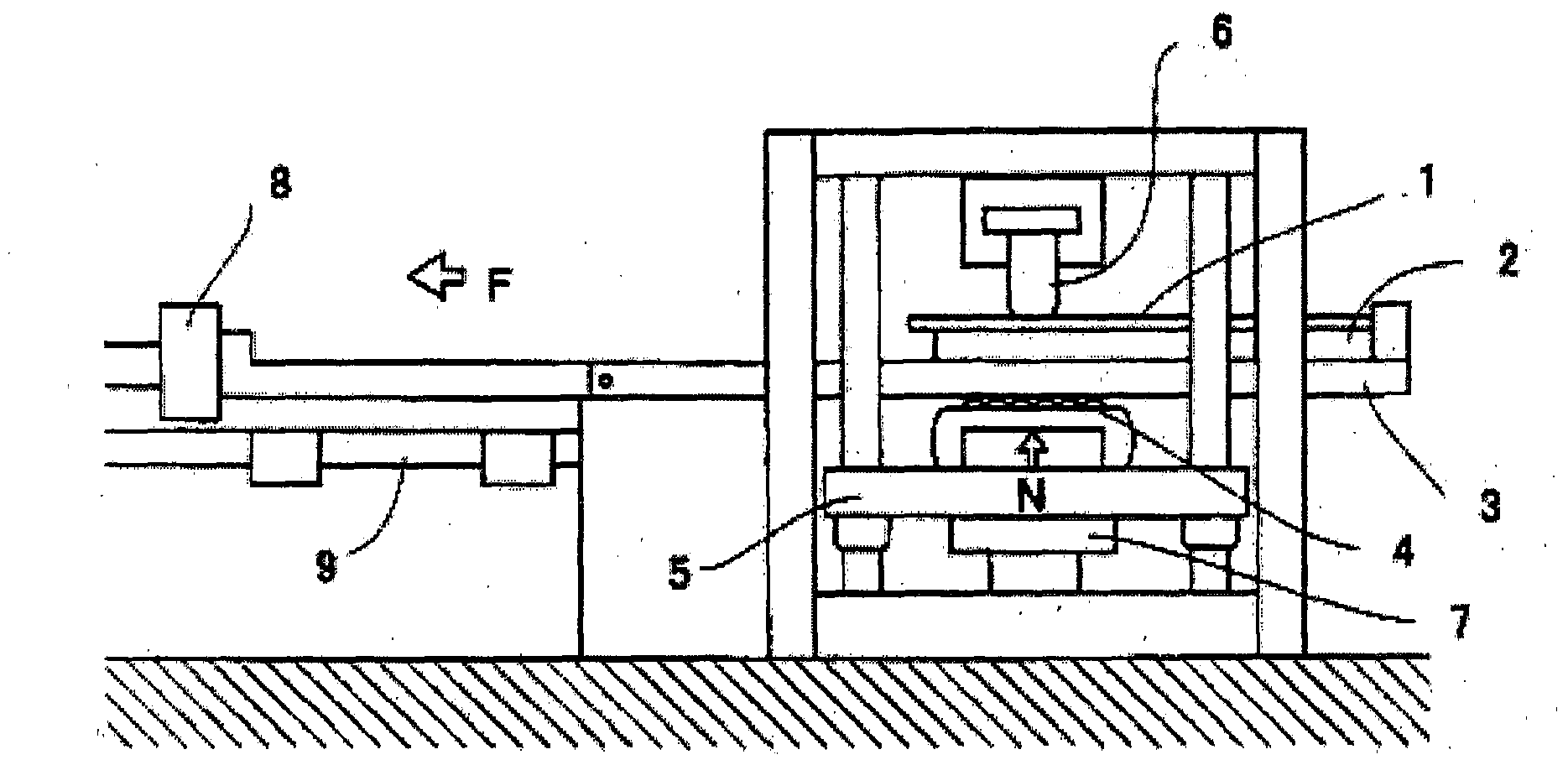

[0070] The same steel as in Example 1 was hot-rolled, pickled, and cold-rolled by a known method to produce a steel plate with a thickness of 1.5 mm. The obtained steel sheet is passed through a continuous hot-dip galvanizing production line equipped with a preheating furnace, a heating furnace with a direct-fired burner, a radiant tube type annealing furnace, a cooling furnace, a hot-dip galvanizing device, and an alloying furnace, and is subjected to oxidation treatment and reduction Annealed to obtain a hot-dip galvanized steel sheet.

[0071] The oxidation treatment was performed under the conditions shown in Table 2 using a heating furnace equipped with a direct-fired burner. The furnace with direct fire burners is divided into 4 zones, each of which has the same length. The direct fire burner uses COG as fuel, and adjusts the O of the atmosphere by changing the air ratio of the front section (1-3 zones) and the rear section (4 zones) of the heating furnace. 2 concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com