Hot melt adhesives for electrical devices

A technology of hot-melt adhesives and electrical devices, applied in the direction of adhesive types, grafted polymer adhesives, adhesives, etc., can solve problems such as difficult high-level requirements, and achieve excellent adhesion, adhesion Excellent adhesion and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

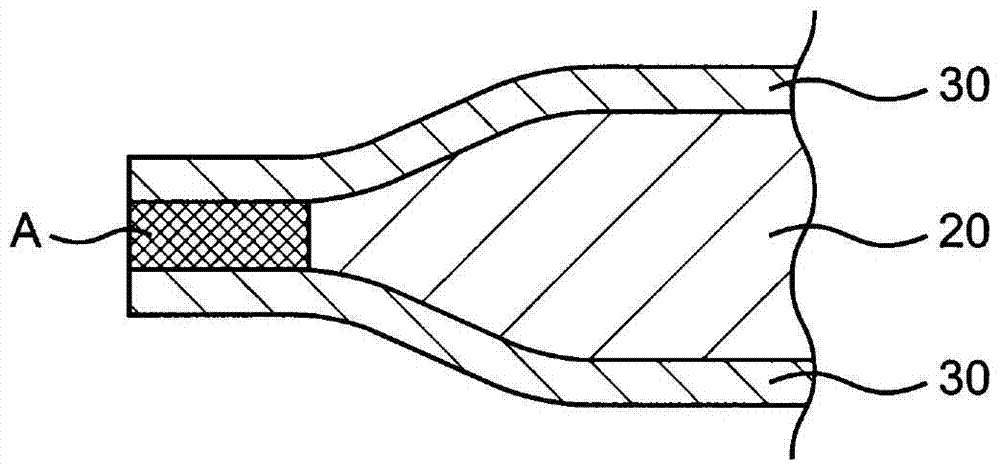

Image

Examples

Embodiment

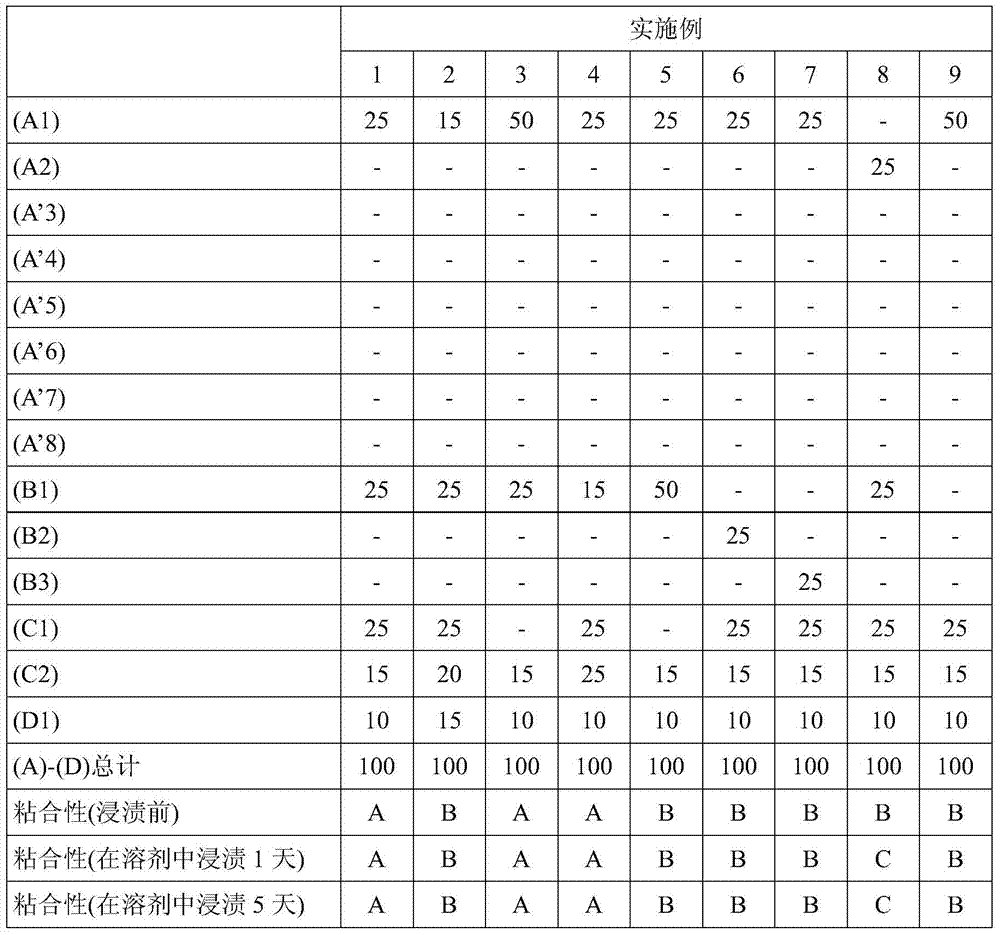

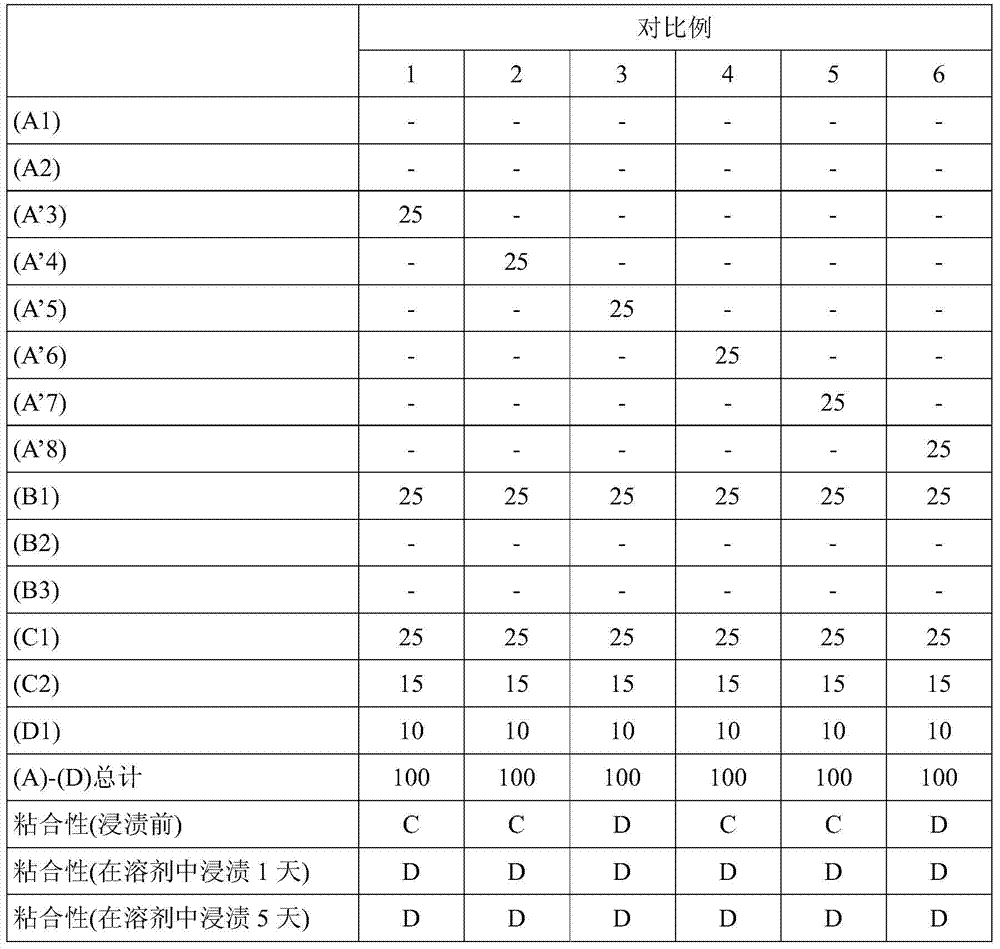

[0098] The present invention will be described in detail through examples and comparative examples, but these examples are for illustrative purposes only and are not intended to be construed restrictively.

[0099] The components used to prepare the hot melt adhesive for electrical devices are shown below.

[0100] (A) Olefin modified polymer

[0101] (A1) Silane-modified amorphous poly-α-olefin (ethylene-propylene-butene copolymer) (glass transition temperature: -29°C, softening point: 100°C, melt viscosity at 190°C: 12,000 mPa·s, VESTOPLAST EP2412 (trade name) manufactured by Evonik Degussa Corporation)

[0102] (A2) Silane-modified polyisobutylene (melt viscosity at 190° C.: 170 mPa·s, EPION EP100S (trade name) manufactured by Kaneka Corporation)

[0103] (A'3) Ethylene-vinyl acetate copolymer (vinyl acetate content: 28% by weight, melt viscosity at 190°C: 23,000 mPa·s, ULTRASEN722 (trade name) manufactured by TOSOH CORPORATION)

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com