Method for preparing OLED light-emitting device with metal-enhanced fluorescence outer conversion layer

A technology for metal-enhanced fluorescence and light-emitting devices, which can be used in organic semiconductor devices, semiconductor/solid-state device manufacturing, and electrical solid-state devices, etc., and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing an OLED light-emitting device with a metal-enhanced fluorescent outer conversion layer, comprising the following steps:

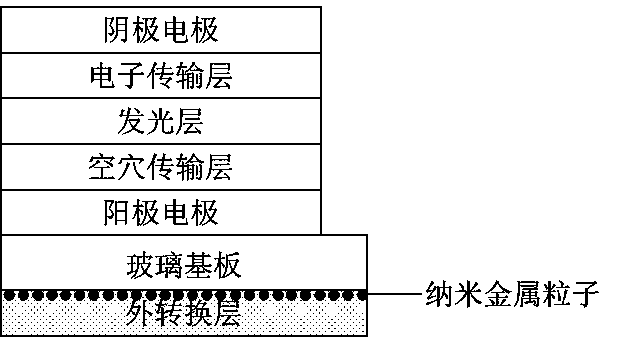

[0026] Such as figure 1 As shown, 1) Preparation of nano-metal particle layer: select glass and metal materials according to the preset structure of glass and fluorescent light-emitting layer; vacuum-deposit a metal layer on clean glass, and then place the glass and metal layer on Carry out heat treatment in a vacuum environment, the heat treatment temperature is 150-450°C, and the heat treatment time is 10-180min; so that the metal layer forms a metal nanoparticle structure;

[0027] 2) Preparation of fluorescent light-emitting layer: according to the preset structure of glass and fluorescent light-emitting layer, select fluorescent light-emitting materials and high molecular polymers; dissolve high molecular polymers in at least one of organic solvents or inorganic solvents, mass percentage 5%-35%; uniformly disperse the flu...

Embodiment 1

[0037] In this embodiment, the glass used is the glass that has been coated with ITO film. The fluorescent luminescent material adopts the green luminescent material Rhodamine B. First, a metal silver film with a thickness of 10nm is formed on the back of the ITO glass by vacuum evaporation, placed in a vacuum environment, heat-treated at a temperature of 150°C for 16 minutes, and then cooled to room temperature, and the silver film on the back of the ITO glass is obtained. A nano-metal Ag particle layer, the nano-Ag layer has a nano-metal structure. Mix polyvinyl alcohol PVA evenly with distilled water to obtain a 12% PVA aqueous solution, and then add rhodamine B (RB) to the above solution to obtain 6.23×10 -4 mol / l RB solution. Then, a RB-PVA fluorescent layer with a thickness of 3 μm was coated on the glass with the nanometer metal particle layer by spin coating.

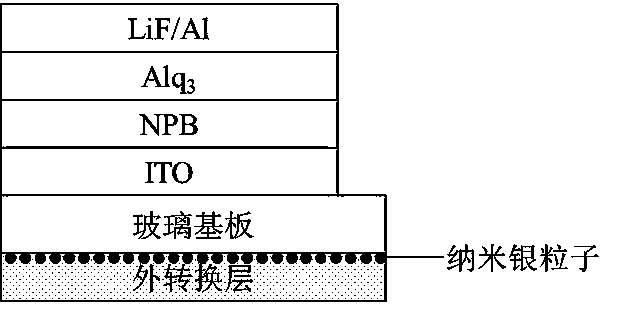

[0038] Such as image 3 As shown, followed by vacuum evaporation method, on the ITO glass vacuum evaporat...

Embodiment 2

[0040]In this embodiment, the glass used is the glass that has been coated with ITO film. The fluorescent luminescent material adopts the red fluorescent luminescent material DCJTB (provided by China Reagent Network). First, according to the method of the nano-metal particle layer in Example 1, a nano-metal particle layer on the ITO glass is obtained, and the metal layer has a nano-metal structure. Mix polymethyl methacrylate PMMA evenly with chlorobenzene to obtain a 20% PMMA-chlorobenzene solution. DCJTB was added to the above solution to obtain a mass percentage of DCJTB dye of 0.5 wt%. Then, a fluorescent light-emitting layer of DCJTB-PMMA with a thickness of 2 μm was coated on the glass with the nano-metal particle layer by a spin coating method.

[0041] Such as Figure 4 As shown, followed by vacuum evaporation method, vacuum evaporation hole transport layer NPB 35nm, blue light emitting layer TBADN: 3%DSA-ph 15nm, electron transport layer TPBi 40nm and cathode elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com