Centrifugal air conditioner unit with water as refrigerants and running method

An air-conditioning unit and centrifugal technology, applied in the field of centrifugal air-conditioning units, can solve the problems of reduced energy utilization efficiency, high water vapor flow rate, and large occupied volume, and achieve the effects of improving energy efficiency ratio, reducing overall volume, and reducing pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

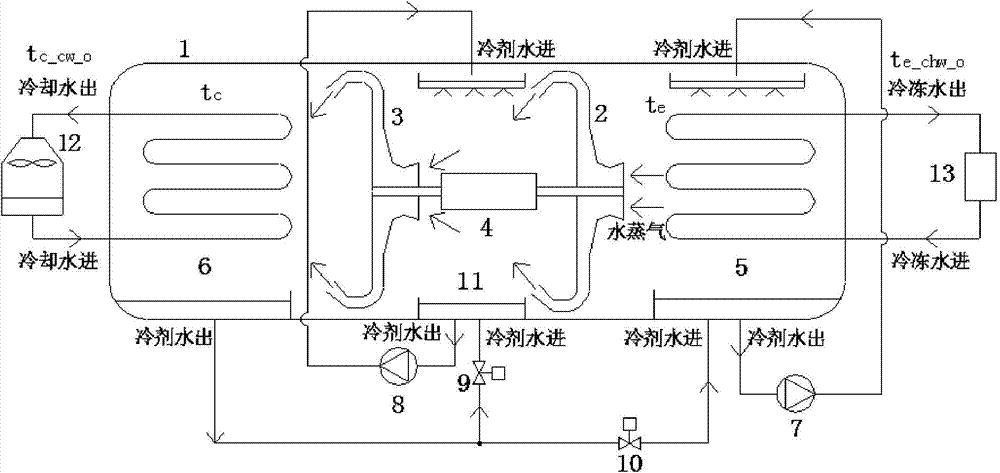

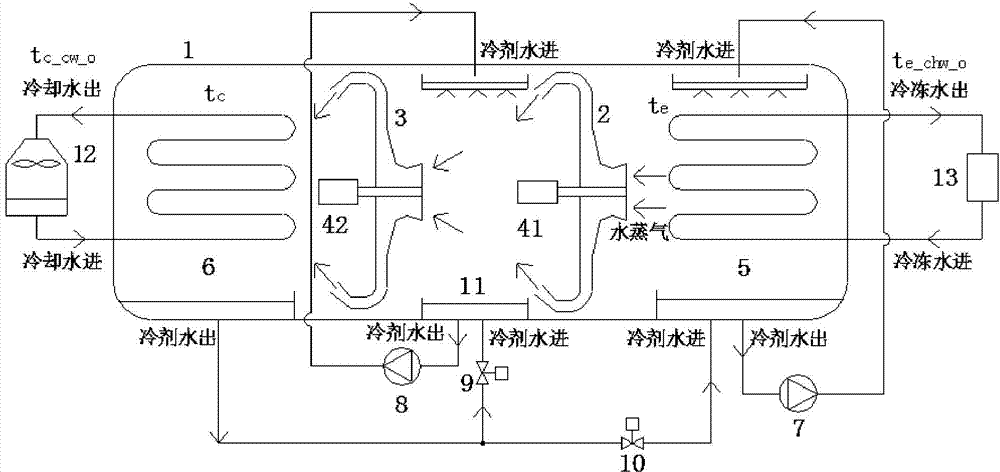

[0039] A kind of water provided by the invention is used as the centrifugal air-conditioning unit of refrigerant, such as figure 2 As shown, it includes: an evaporator 5, a compressor, a motor and a condenser 6 arranged in a fully enclosed container 1, and a first circulation channel for supplementing refrigerant water to the evaporator 5 by the condenser 6 arranged outside the container 1 , the evaporator 5 can exchange heat with the outside through the internal indirect contact heat exchange mode while evaporating the refrigerant water circulated by the evaporator circulating pump 7; The low-temperature water vapor generated by the condenser 5 is compressed, and then the high-temperature water vapor is discharged through the exhaust port; the condenser 6 can convert the high-temperature water vapor into refrigerant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com