Engineering strain capable of producing succinic acid at low pH value and method for producing succinic acid by fermentation

A technology for producing succinic acid and genetically engineered bacteria is applied in the field of bioengineering to achieve the effect of promoting progress and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Using LB medium, cultivate Escherichia coli AFP111 to OD at 37°C under aerobic conditions 600 = 0.5~0.6, using CaCl 2 prepared by the method lacking the lactate dehydrogenase gene ( wxya ), pyruvate formate lyase gene ( PPML ) activity and the phosphotransferase system ptsG Escherichia coli AFP111 competent strain with spontaneous mutation of gene chromosome;

[0037] The formula of LB medium was: peptone 10 g / L, yeast powder 5 g / L, NaCl 5 g / L. (2) Synthesize primers without restriction sites,

[0038] Upstream primer: 5'-ACACGAGTCCTTTGCACTTGCTTACTTT-3';

[0039] Downstream primer: 5'-CGCTCCCTTGTCTTATAACCATTCAGAC-3'.

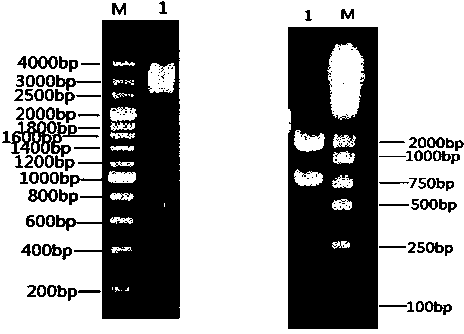

[0040] extract E. coli JM109 (preserved in this laboratory) genome, with E. coli The JM109 genome was used as a template, and the target gene fragment was amplified by PCR. The specific reaction conditions were: 94 °C for 5 min; (94 °C for 45 s, 60 °C for 45 s, 72 °C for 4 min, 36 cycles); 72 °C for 10 min. Purified and amplified conta...

Embodiment 2

[0046] The Escherichia coli BA600 constructed in Example 1 was used as the starting strain. 1% (v / v) inoculum was transferred from the cryopreservation tube to the test tube, cultivated overnight at 37°C and 200 rpm, and then transferred to the Erlenmeyer flask with 1% (v / v) inoculum, and cultivated at 37°C and 200 rpm6 -8 h to obtain the bacterial solution in the logarithmic growth phase; inoculate the bacterial solution in the logarithmic growth phase into a 500 mL continuous culture device with 300 mL of fermentation medium at an inoculation amount of 10% (v / v), and place it in a water bath at 37 °C. Heat, pass through filter-sterilized CO 2 Maintain the anaerobic environment, and add fresh fermentation medium to the culture device at a rate of 1.5 mL / h. Regularly take samples to detect the density of bacteria in the culture device, when the density of bacteria in the reactor reaches OD 600 = 2 to 3, and there was no significant change for 48 h, indicating that the bacter...

Embodiment 3

[0051] Different carbonates with different molar concentrations were added to the fermentation medium, and CO was passed for 2 min before and after sterilization. 2 After the final pH value, the carbonates that can adjust the pH value to around 5.6 are screened out.

[0052] The formula of the fermentation medium is: citric acid 3 g L -1 , Na 2 HPO 4 12H 2 O 4 g L -1 , KH 2 PO 4 8 g L -1 , (NH 4 ) 2 HPO 4 8 g L -1 , NH 4 Cl 0.2 g L -1 , (NH 4 ) 2 SO 4 0.75 g·L -1 , MgSO 4 ·7H 2 O 1 g L -1 , CaCl 2 2H 2 O 10.0 mg·L -1 , ZnSO 4 ·7H 2 O 0.5 mg L -1 , CuCl 2 2H 2 O 0.25 mg L -1 , MnSO 4 ·H 2 O 2.5 mg L -1 , CoCl 2 ·6H 2 O 1.75 mg L -1 , H 3 BO 3 0.12 mg·L -1 , Al 2 (SO4 ) 3 1.77 mg·L -1 , Na 2 MoO 4 2H 2 O 0.5 mg L -1 , ferric citrate 16.1 mg·L -1 , 20.0 mg L -1 VB 1 , 2.0 mg L -1 Biotin, glucose 30-40 g / L.

[0053] Table 1 Comparison of pH adjusted by different carbonates obtained by screening

[0054]

[0055] The pH reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com