Achromobacter xylosoxidans strain for producing carboxymethyl cellulase

A technology for carboxymethyl cellulose and cellulose degradation, which is applied in the field of bioengineering and can solve problems such as lack of alkaline cellulase production strains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Screening, isolation and identification of strains

[0026] The first step: sampling

[0027] Compost samples in the suburbs of Wuming County, Nanning City, Guangxi Zhuang Autonomous Region.

[0028] Step 2: Primary screening, secondary screening and purification

[0029] Take 1g sample, add 10ml sterile distilled water, shake well, stand for 30 minutes, take the supernatant and dilute 10 5 CMC-Congo red plate screening medium was coated and inoculated, cultured at 30°C for 72 hours until colonies grew, picked the colonies with larger transparent hydrolysis circles, inoculated with CMC liquid fermentation medium, cultured in a shake flask at 37°C, 200rpm for 24 hours, and measured The alkaline CMC enzyme activity of the culture medium. Select the most vigorous culture flask, inoculate the CMC-Congo red plate screening medium with the bacterial solution streaked, and purify the strain 3 times, and finally obtain a high-yielding strain of alkaline cellulase, named 7B, ...

Embodiment 2

[0035] Example 2 Detection of cellulase production by strains

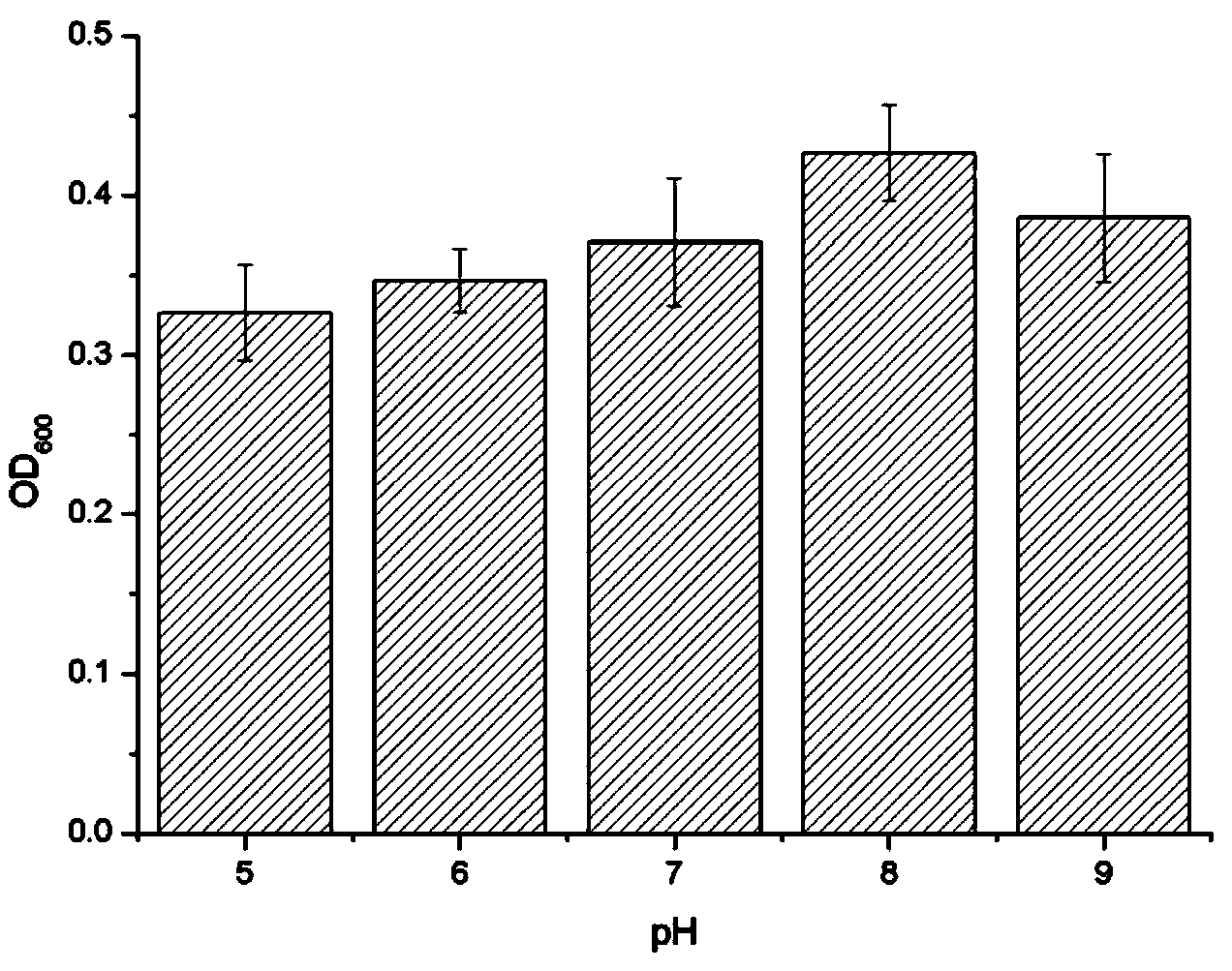

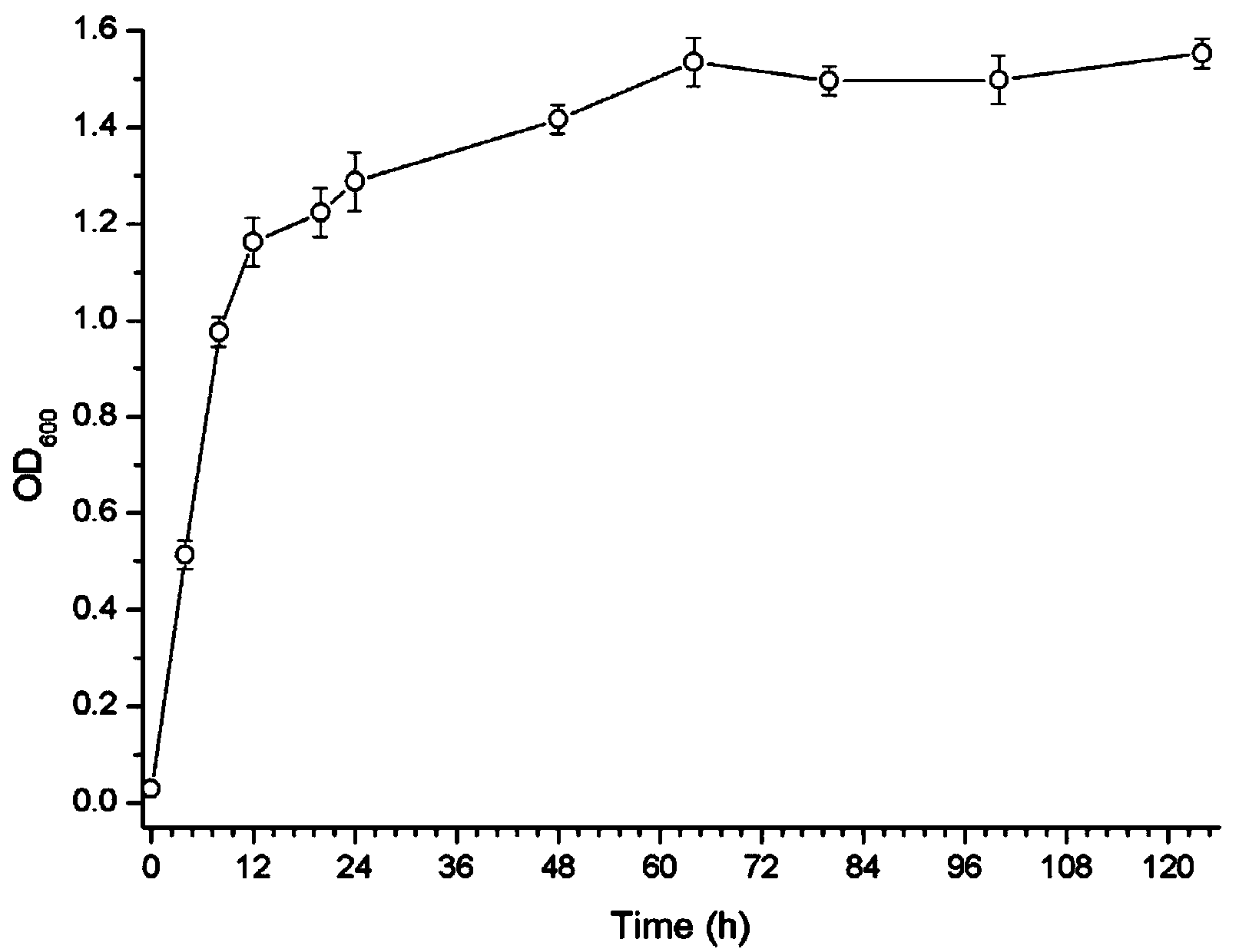

[0036] according to figure 1 with figure 2 As shown in the optimum temperature and pH for growth, strain 7B was inoculated with CMC fermentation medium and cultivated, and the enzyme production curve was drawn. The results are as follows Figure 4 Shown. The preparation method of the crude enzyme solution is as follows: the activated strain is inoculated with CMC fermentation medium, cultivated at 30°C, 200rpm for 48h, the culture solution is taken, centrifuged at 4000rpm at 4°C for 10min, the supernatant is taken, and 55% (NH 4 ) 2 SO 4 Precipitate, centrifuge at 10,000 rpm for 10 min at 4°C, collect the precipitate, add the same volume of the culture solution to the pH 8.0, 0.1 mol / L Tris-HCl buffer to dissolve. Using CMC sodium salt as a substrate, the activity of endocellulose, that is, CMC enzyme activity, was determined. The enzyme reaction system contains 0.5 ml of crude enzyme solution, 1% CMC sodium salt, a...

Embodiment 3

[0040] Example 3 Treatment of BTEX and refractory chelating agent

[0041] This example was performed at the laboratory level. A 10-fold diluted LB medium with 2% CMC cellulose was used to simulate a sewage water body rich in organic matter. Respectively: adding 0.02% ethylbenzene to simulate BTEX polluted industrial wastewater; adding 0.1% IDS (imino disuccinic acid) to simulate refractory chelating agent polluting water; adding 0.1% endosulfan to simulate refractory pesticide polluting water. The experiment used 100mL culture solution, inoculation amount 1%, 30℃, rotating speed 180rpm shake flask culture for 48 hours. Sampling every 4 hours to detect residual COD and pollutants. Among them, the determination of ethylbenzene residues adopts n-hexane extraction + gas chromatography, wherein the chromatographic column is HP-Innoax capillary column, column temperature is 90℃, column flow rate is 1mL / min, and carrier gas is N 2 ; COD determination uses potassium dichromate oxidati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com