Mold-proof silicone sealant and preparation method thereof

A silicone sealant and anti-mildew technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problem of poor compatibility between anti-fungal agents and basic rubber materials, decreased storage stability of rubber materials, yellowing, etc. problems, to achieve good compatibility, improve thixotropy, and improve the effect of mildew resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

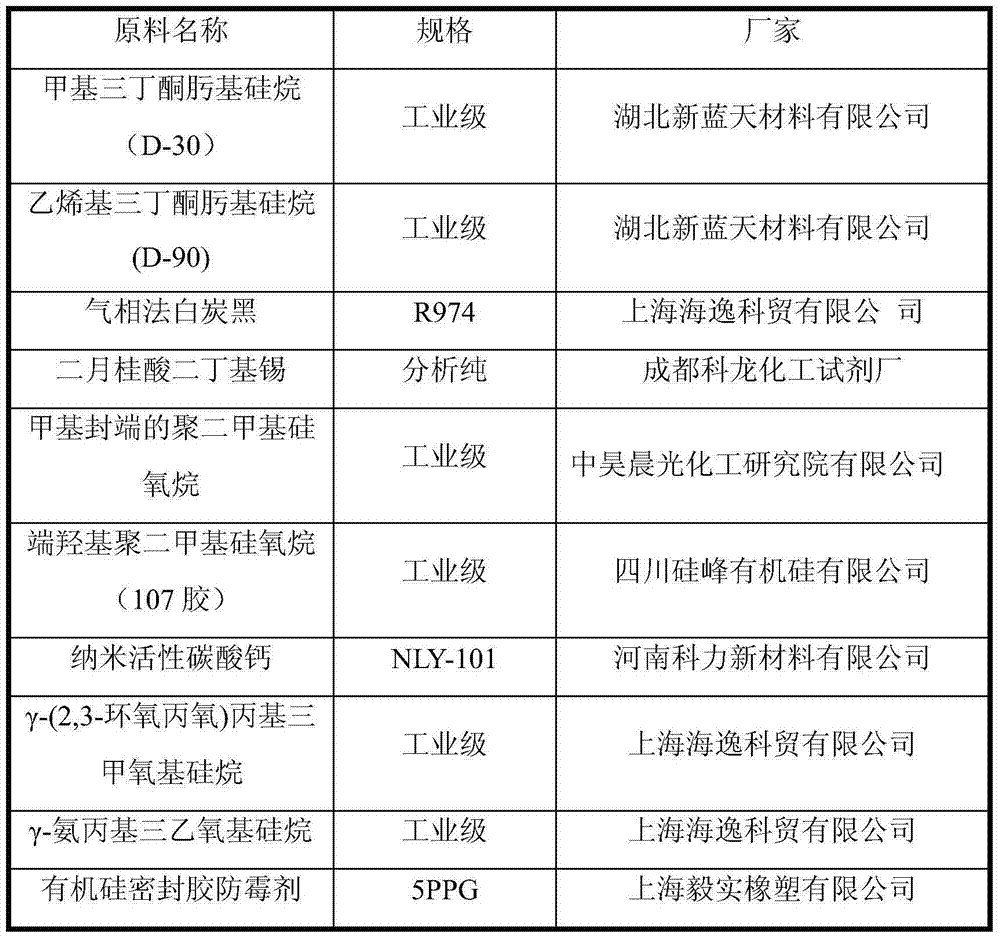

Image

Examples

preparation example Construction

[0034] The present invention also provides a preparation method of the above-mentioned mildew-proof silicone sealant, comprising the following steps:

[0035] a. Stir the hydroxyl-terminated polydimethylsiloxane, plasticizer and fumed silica at a temperature of 80-140°C for 30-60 minutes under a vacuum degree ≥ 0.09 MPa to obtain a rubber compound;

[0036] b. After cooling the rubber material to room temperature, add a crosslinking agent, antifungal agent, silane coupling agent, and catalyst in sequence, and stir for 30-45 minutes under a vacuum ≥ 0.09 MPa to obtain an antifungal silicone sealant.

[0037] Remove the moisture in hydroxyl-terminated polydimethylsiloxane, plasticizer, and fumed silica at a fixed temperature and vacuum range, so as not to affect the storage stability of the rubber compound due to excessive moisture content in the raw materials . Among them, the main purpose of adding additives under vacuum conditions in step b is also to make rubber in a dry en...

Embodiment 1

[0042]Add 100 parts of 50000mPa.s 107 glue (hydroxyl-terminated polydimethylsiloxane) into the dynamic mixer, add 80 parts of methyl-terminated polydimethylsiloxane with a kinematic viscosity of 3000mPa.s and specific surface area 170m 2 / g 20 parts of hydrophobic fumed silica, heat up to 110°C, stir and dehydrate for 45min under the condition of vacuum degree ≥ 0.09MPa, to obtain rubber compound. ; Cool the above-mentioned rubber material, and add 8 parts of phenyltributylketoxime-based silane, 1.5 parts of silicone sealant fungicide, 2.5 parts of γ-aminopropyltrimethoxysilane and two 0.3 parts of dibutyltin laurate, stirred for 30 minutes under the condition of vacuum degree ≥ 0.09MPa to make anti-mildew silicone sealant.

Embodiment 2

[0044] Add 100 parts of 50000mPa.s 107 glue (hydroxyl-terminated polydimethylsiloxane) into the dynamic mixer, add 55 parts of methyl-terminated polydimethylsiloxane with a kinematic viscosity of 2000mPa.s and specific surface area 26 parts of 170m2 / g hydrophobic fumed silica, heated up to 120°C, stirred and dehydrated for 45min under the condition of vacuum degree ≥ 0.09MPa, to obtain rubber compound. Cool the above-mentioned rubber material, and add 6 parts of vinyl tributylketone oxime silane, 0.6 parts of silicone sealant antifungal agent, γ-(2,3-glycidoxy) propyl Stir 2.5 parts of trimethoxysilane and 0.3 parts of dibutyltin dilaurate for 30 minutes under the condition of vacuum degree ≥ 0.09 MPa to make anti-mildew silicone sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com