Anti-static polyvinyl chloride sole material and manufacturing method thereof

A polyvinyl chloride and shoe sole material technology, applied in the field of shoe sole materials, can solve the problems of high surface resistivity, failure of electronic components, explosion of flammable items, etc., and achieve the effects of improving antistatic performance, prolonging service life and preventing aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

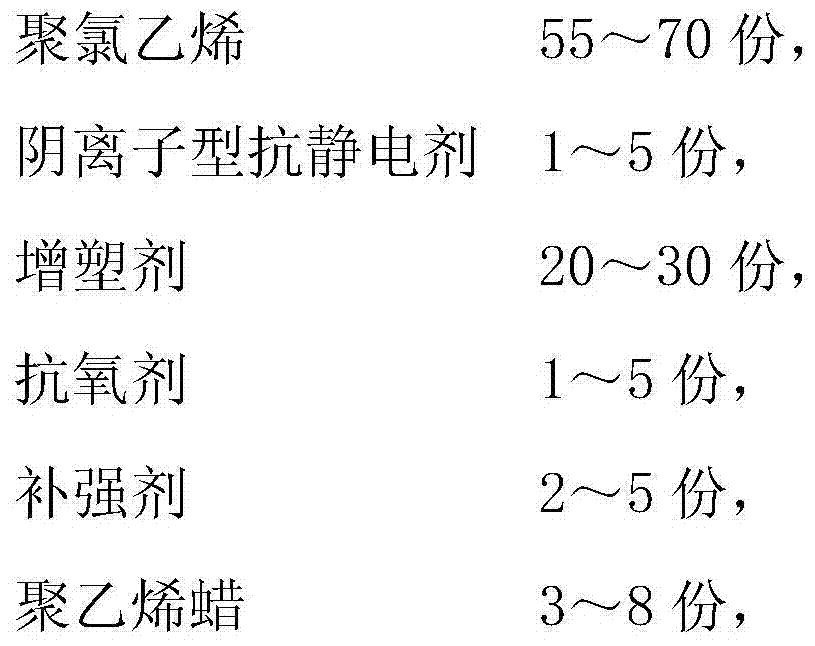

[0023] A kind of antistatic polyvinyl chloride shoe sole material, its weight part consists of:

[0024]

[0025] Its manufacturing method comprises the following steps:

[0026] (1) drying: select the anionic antistatic agent according to the formula, and dry it;

[0027] (2) Mixing: According to the formula, the dried quaternary ammonium salt type cationic surfactant and other components in the formula are mixed to obtain a uniformly mixed material;

[0028] (3) extrude: the material that step (2) obtains is added extruder, extrudes and obtains antistatic polyvinyl chloride pellet;

[0029] (4) Injection molding: adding the antistatic polyvinyl chloride pellets obtained in step (3) into an injection molding machine, and injection molding to obtain an antistatic polyvinyl chloride sole material.

Embodiment 2

[0031] A kind of antistatic polyvinyl chloride shoe sole material, its weight part consists of:

[0032]

[0033] Its manufacturing method comprises the following steps:

[0034] (1) drying: select the anionic antistatic agent according to the formula, and dry it;

[0035] (2) Mixing: According to the formula, the dried quaternary ammonium salt type cationic surfactant and other components in the formula are mixed to obtain a uniformly mixed material;

[0036] (3) extrude: the material that step (2) obtains is added extruder, extrudes and obtains antistatic polyvinyl chloride pellet;

[0037] (4) Injection molding: adding the antistatic polyvinyl chloride pellets obtained in step (3) into an injection molding machine, and injection molding to obtain an antistatic polyvinyl chloride sole material.

Embodiment 3

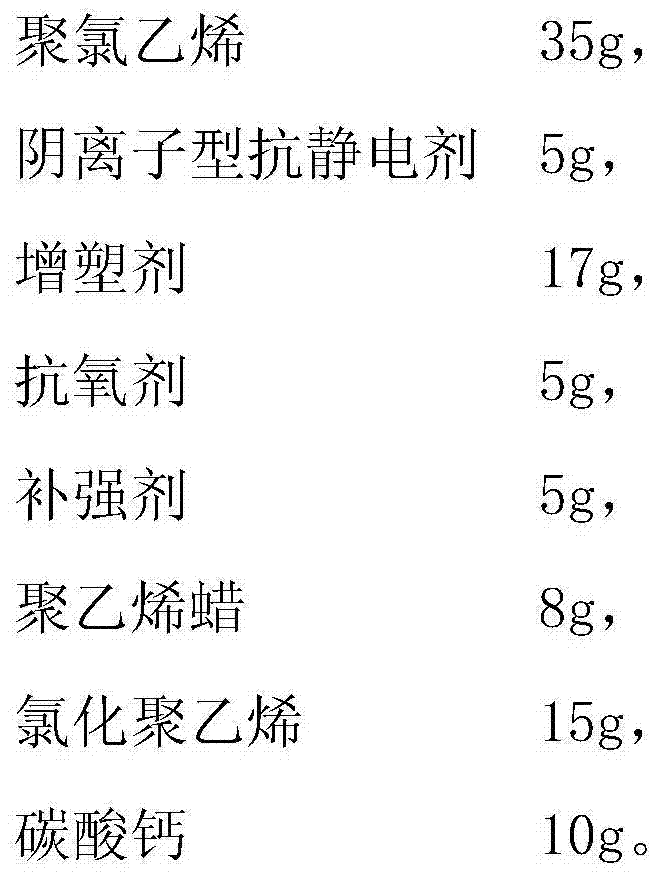

[0039] A kind of antistatic polyvinyl chloride shoe sole material, its weight part consists of:

[0040]

[0041]

[0042] Its manufacturing method comprises the following steps:

[0043] (1) drying: select the anionic antistatic agent according to the formula, and dry it;

[0044] (2) Mixing: According to the formula, the dried quaternary ammonium salt type cationic surfactant and other components in the formula are mixed to obtain a uniformly mixed material;

[0045] (3) extrude: the material that step (2) obtains is added extruder, extrudes and obtains antistatic polyvinyl chloride pellet;

[0046] (4) Injection molding: adding the antistatic polyvinyl chloride pellets obtained in step (3) into an injection molding machine, and injection molding to obtain an antistatic polyvinyl chloride sole material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com