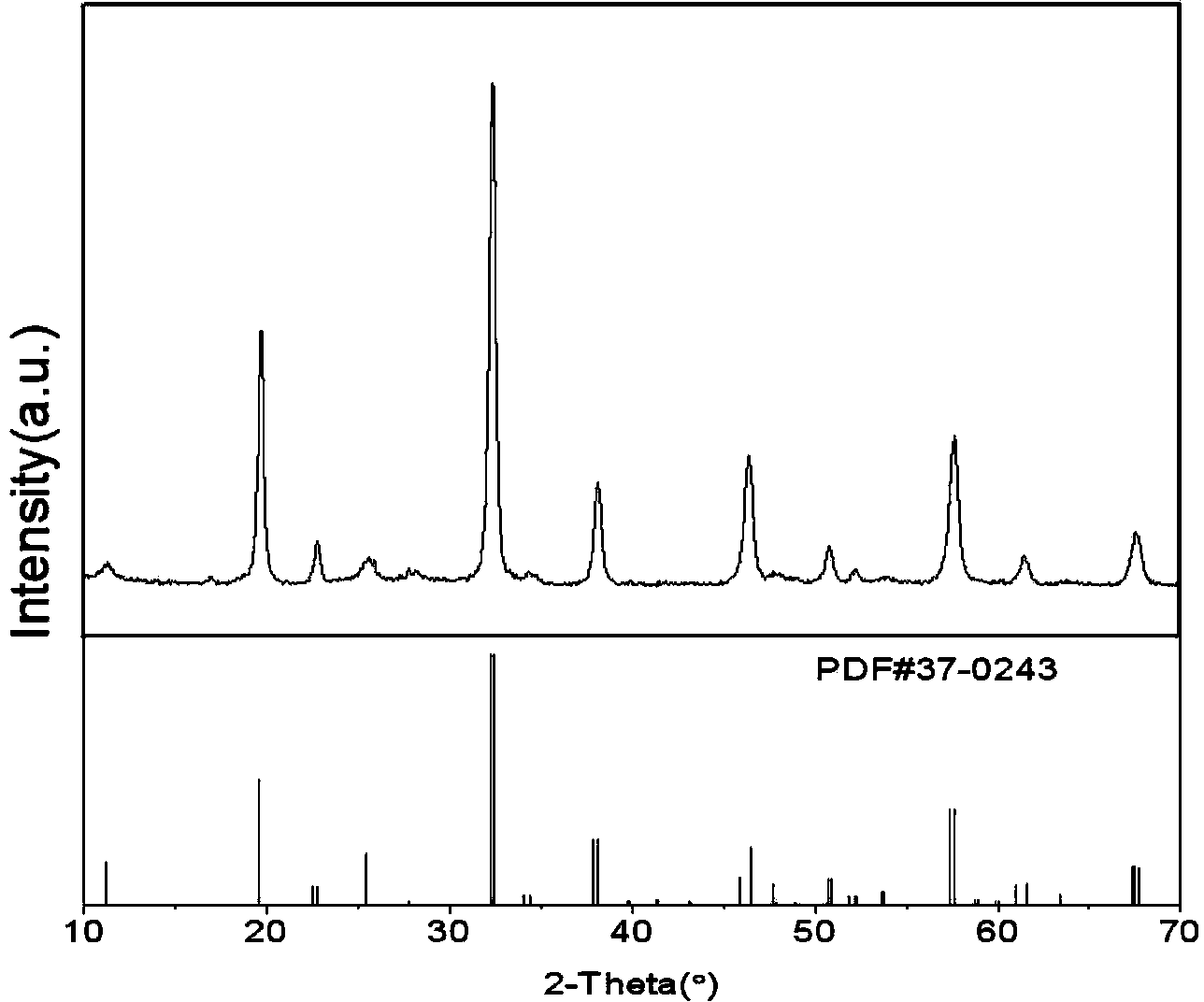

Method for preparing NaLaMgWO6 powder by using two-step method

A powder and step technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of reduced luminous efficiency of phosphors, difficulty in obtaining spherical particles, uneven particle size distribution, etc., and achieve good crystallization performance. , Small particle size, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A two-step method to prepare NaLaMgWO 6 The method of powder, comprises the following steps:

[0033] 1) According to the stoichiometric ratio, weigh and synthesize 0.02mol of NaLaMgWO 6 required NaNO 3 , La(NO 3 ) 3 , magnesium acetate (C 4 h 6 MgO 4 ), ammonium tungstate ((NH 4 ) 10 W 12 o 41 ), and be dissolved in deionized water (the quality of deionized water is 4 times of the total mass of raw materials required), and add 0.004mol of citric acid (C 6 h 8 o 7 ), was prepared into solution A;

[0034] 2) Add HNO dropwise to solution A 3 Carry out pH adjustment, adjust pH to 7;

[0035] 3) After the pH adjustment, the solution A was placed in a hydrothermal kettle for hydrothermal treatment. The hydrothermal treatment temperature was 180° C., the hydrothermal treatment time was 12 hours, and the filling degree of the hydrothermal kettle reaction was 80%;

[0036] 4) After the hydrothermal treatment is completed, the sample in the hydrothermal kettle i...

Embodiment 2

[0040] A two-step method to prepare NaLaMgWO 6 The method of powder, comprises the following steps:

[0041] 1) According to the stoichiometric ratio, weigh and synthesize 0.02mol of NaLaMgWO 6 required NaNO 3 , La(NO 3 ) 3 , magnesium acetate (C 4 h 6 MgO 4 ), ammonium tungstate ((NH 4 ) 10 W 12 o 41 ), and be dissolved in deionized water (the quality of deionized water is 5 times of the total mass of raw materials required), and add 0.002mol of citric acid (C 6 h 8 o 7 ), was prepared into solution A;

[0042] 2) Add HNO dropwise to solution A 3 Carry out pH adjustment, adjust pH to 8;

[0043] 3) After the pH adjustment, the solution A was placed in a hydrothermal kettle for hydrothermal treatment. The hydrothermal treatment temperature was 165° C., the hydrothermal treatment time was 18 hours, and the filling degree of the hydrothermal kettle reaction was 70%;

[0044] 4) After the hydrothermal treatment is completed, the sample in the hydrothermal kettle i...

Embodiment 3

[0048] A two-step method to prepare NaLaMgWO 6 The method of powder, comprises the following steps:

[0049] 1) According to the stoichiometric ratio, weigh and synthesize 0.02mol of NaLaMgWO 6 required NaNO 3 , La(NO 3 ) 3 , magnesium acetate (C 4 h 6 MgO 4 ), ammonium tungstate ((NH 4 ) 10 W 12 o 41 ), and be dissolved in deionized water (the quality of deionized water is 3 times of the total mass of raw materials required), and add 0.001mol of citric acid (C 6 h 8 o 7 ), was prepared into solution A;

[0050] 2) Add HNO dropwise to solution A 3 Carry out pH adjustment, adjust pH to 6;

[0051] 3) After the pH adjustment, the solution A was placed in a hydrothermal kettle for hydrothermal treatment. The hydrothermal treatment temperature was 150° C., the hydrothermal treatment time was 20 hours, and the filling degree of the hydrothermal kettle reaction was 60%;

[0052] 4) After the hydrothermal treatment is completed, the sample in the hydrothermal kettle i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com