A method for making automobile tie rod joints

An automobile tie rod and positive extrusion technology, which is applied in the field of auto parts production, can solve the problems of high dimensional accuracy and surface finish, difficult to control product surface finish, and high cost of parts manufacturing, so as to improve mechanical properties, increase labor productivity, The effect of reducing raw materials and processing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

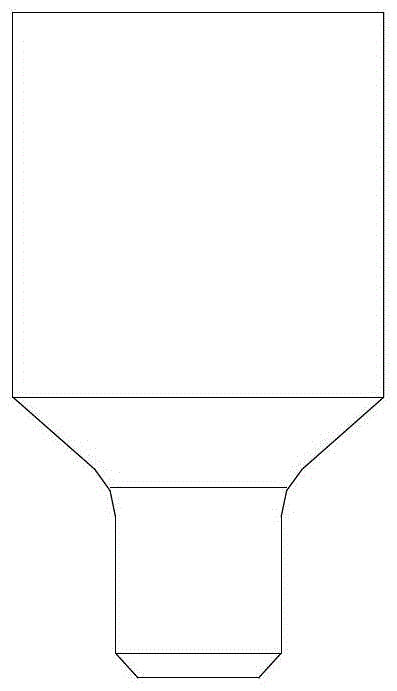

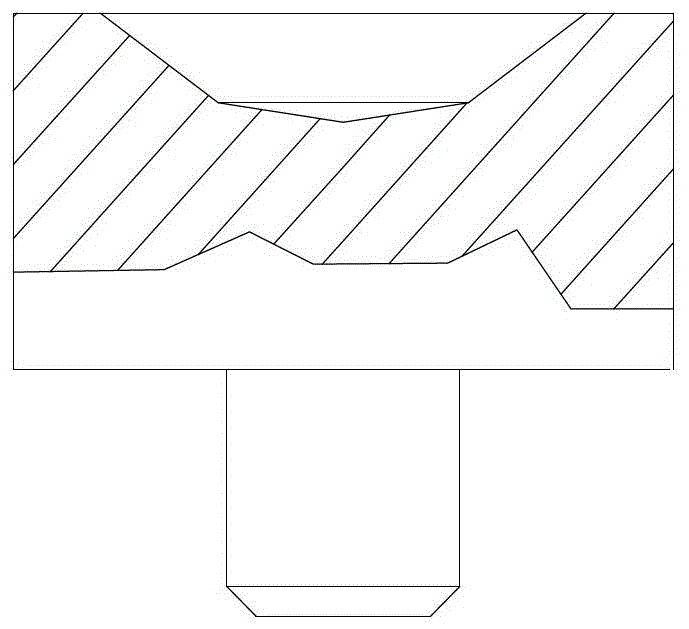

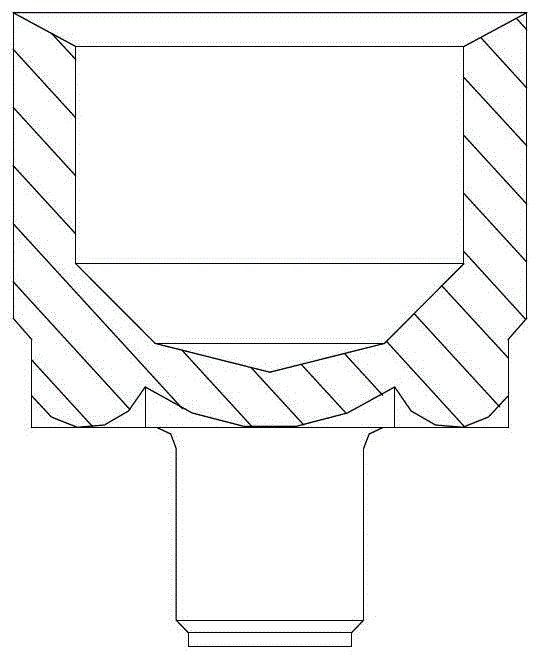

[0028] A method for making a tie rod joint of an automobile, which adopts three extrusion processes to complete the forming process of the tie rod joint of an automobile, comprising the following steps:

[0029] 1. Formulate the blank: 1) Take the blank according to the part drawing, and leave a certain gap for the convenience of loading the workpiece); 2) Re-use the three-step forming method for design and check; 3) Calculate the radial dimension of the blank, Use the "Forward Extrusion Carbon Steel Permissible Deformation Table" to provide the lower limit of the transition interval. Since the pressure, friction and temperature on the mold during forward extrusion are much greater than those during upsetting, it is in a relatively harsh working environment. Down. Therefore, within the allowable range, select the diameter of the blank that has a small amount of deformation during forward extrusion. 4) Re-check the deformation of each process, including forward extrusion, upse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com