Annular metal foam straight hole nozzle of high-speed jetting device

A technology of high-speed jet flow and metal foam, which is applied in the direction of injection devices and liquid injection devices, and can solve the problems of improving the jet performance of jet devices with metal foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

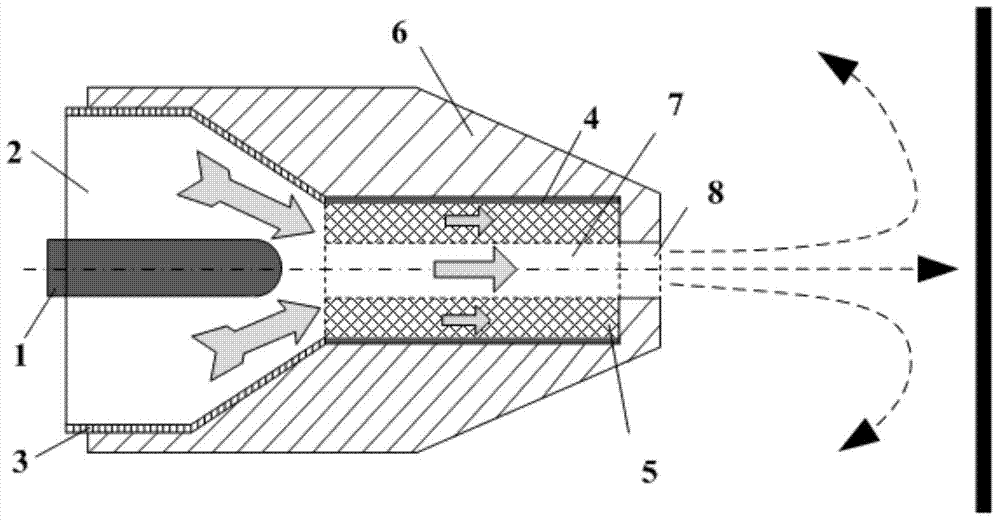

[0021] Specific implementation: combination figure 1 with figure 2 To illustrate, the annular metal foam straight-hole nozzle of a high-speed jet device of this embodiment includes a fixed shaft 1, a mixing chamber 2, a jet tube 4, and a nozzle sleeve 6, wherein a nozzle sleeve is fixed outside the mixing chamber 2 and the jet tube 4 6. The fixed shaft 1 is located in the mixing cavity 2. The mixing cavity 2 is enclosed by the surrounding mixing cavity wall 3, and the nozzle sleeve 6 is provided with jet holes 8; the annular metal foam straight hole nozzle of the high-speed jet device also includes The metal foam layer 5, the outer diameter of the metal foam layer 5 is the same as the inner diameter of the jet tube 4, the metal foam layer 5 is installed on the inner wall of the jet tube 4, the metal foam layer 5 is provided with a hollow area 7, the mixing cavity 2 and the jet tube 4 The connecting section is in the shape of a truncated cone with a tapered cross-sectional area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com