Method for preparing multiphase composite catalyst based on sludge treatment, product and application of product

A sludge treatment and composite technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of sludge material that has not been further reported and has not been completely solved. , to achieve the effect of low processing cost, simple operation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 0.001mol manganese sulfate aqueous solution (10ml, 0.1mol / L) into 400ml wet sludge with a water content of 80%, stir for 20min, mix well and let stand for 12h, then add 10ml, 0.12mol / L ammonium persulfate (0.0012mol) aqueous solution, stirred and mixed at room temperature, then carried out hydrothermal reaction, the temperature was 120°C, and the time was 12h. After the hydrothermal reaction, it was naturally cooled to room temperature, centrifuged, the obtained solid was washed with water, and finally dried to obtain sludge-based active MnO x , wherein x is generally between 3-4, and the following examples are the same.

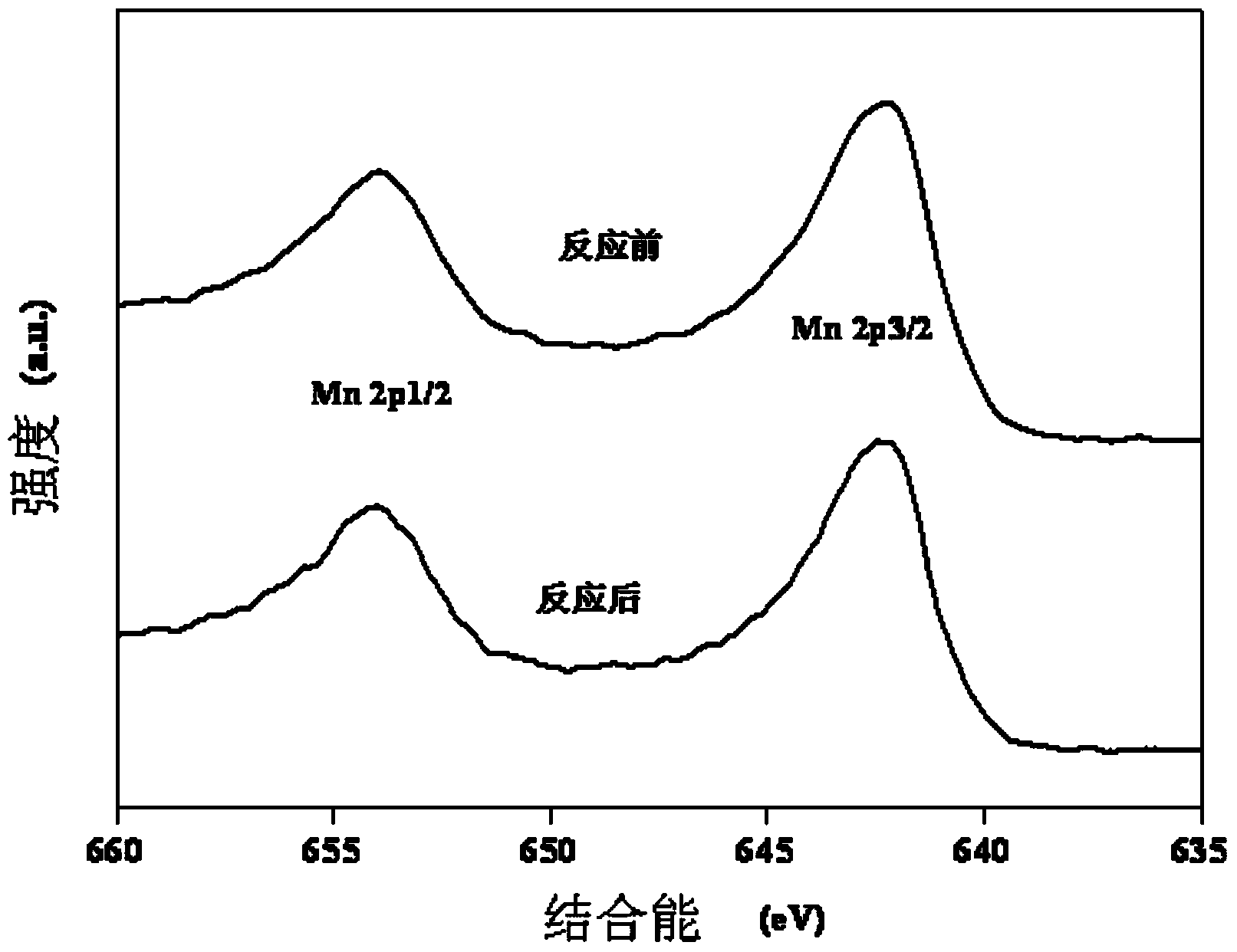

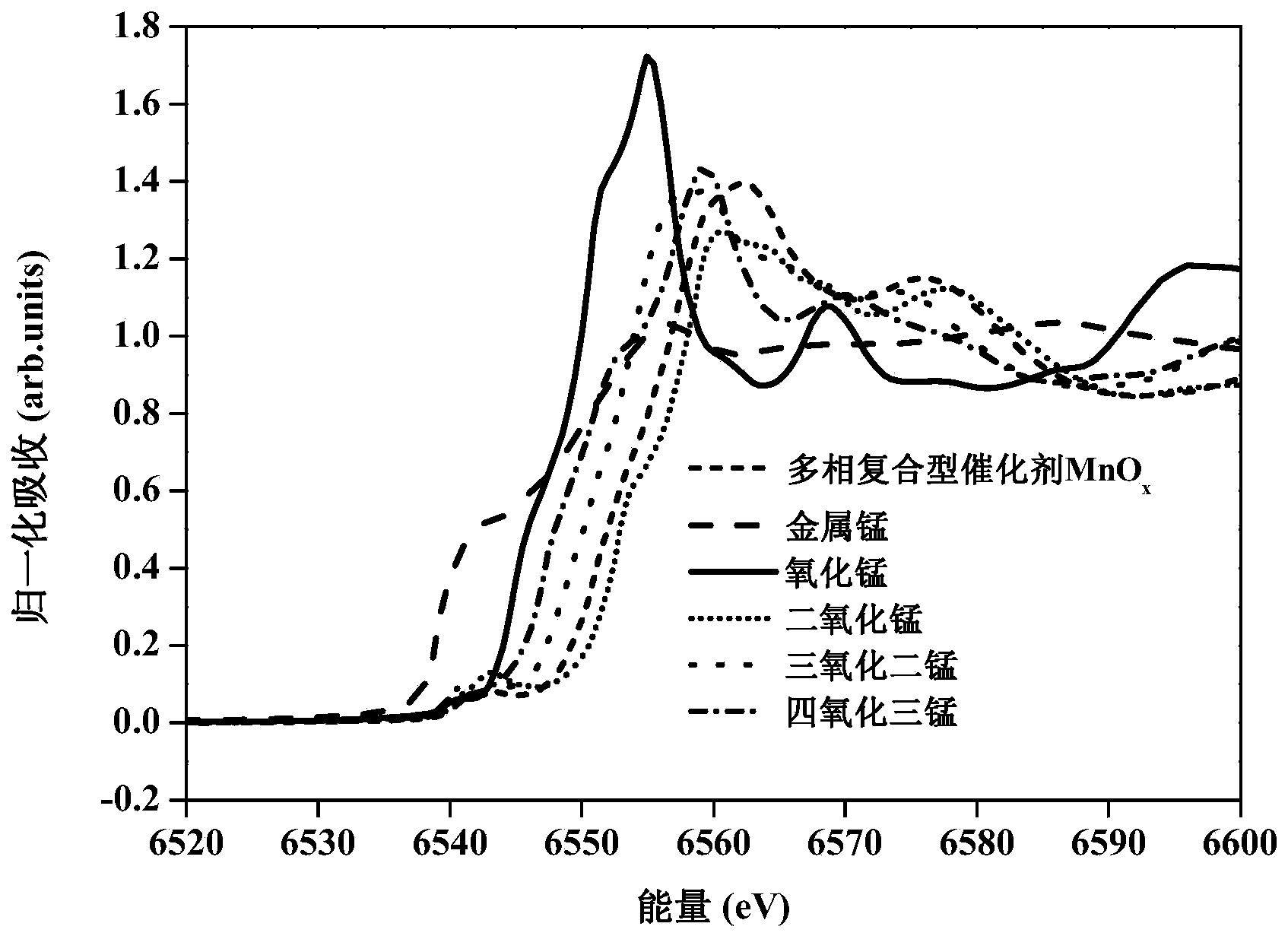

[0039] The heterogeneous composite catalyst MnO prepared in this embodiment x The performance measurements were carried out separately, and the test results were as follows: figure 1 , figure 2 , image 3 Shown:

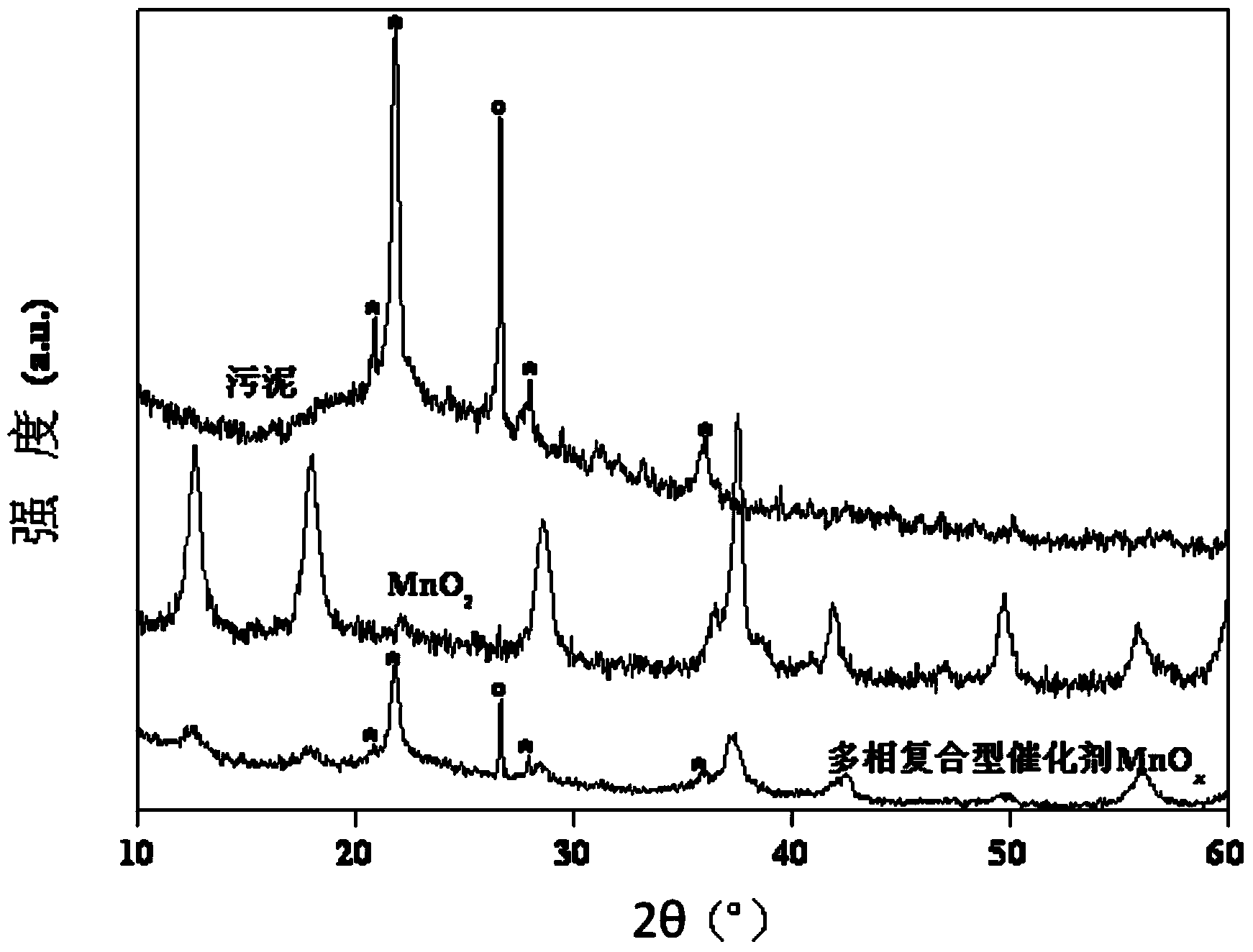

[0040] figure 1 MnO x , manganese dioxide and sludge X-ray diffraction pattern, by figure 1 It can be seen that the sludge con...

Embodiment 2

[0045] Add 0.002mol manganese sulfate aqueous solution (10ml, 0.2mol / L) into 400ml wet sludge with a water content of 80%, stir for 20min, mix well and let stand for 12h, then add 10ml, 0.24mol / L ammonium persulfate (0.0024mol) aqueous solution, stirred and mixed at room temperature, then carried out hydrothermal reaction, the temperature was 120°C, and the time was 12h. After the hydrothermal reaction, it was naturally cooled to room temperature, centrifuged, and the obtained solid was washed with water, and finally dried to obtain a multiphase composite Catalyst MnO x .

Embodiment 3

[0047] Add 0.001mol manganese sulfate aqueous solution (10ml, 0.1mol / L) into 400ml wet sludge with a water content of 80%, stir for 20min, mix well and let stand for 12h, then add 10ml, 0.12mol / L ammonium persulfate (0.0012mol) aqueous solution, stirred and mixed at room temperature, then carried out hydrothermal reaction, the temperature was 140°C, and the time was 12h. After the hydrothermal reaction, it was naturally cooled to room temperature, centrifuged, the obtained solid was washed with water, and finally dried to obtain a multiphase composite Catalyst MnO x .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com