Hollow microspheres based on methacryloxy cage silsesquioxane and its preparation method and application

A technology of methacryloyloxy cage and silsesquioxane, which is applied in the field of microspheres with hollow structure and its preparation, can solve the problems of narrow range of monomers of hollow structure microspheres, achieve mild experimental conditions, reduce The effect of simple use and operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

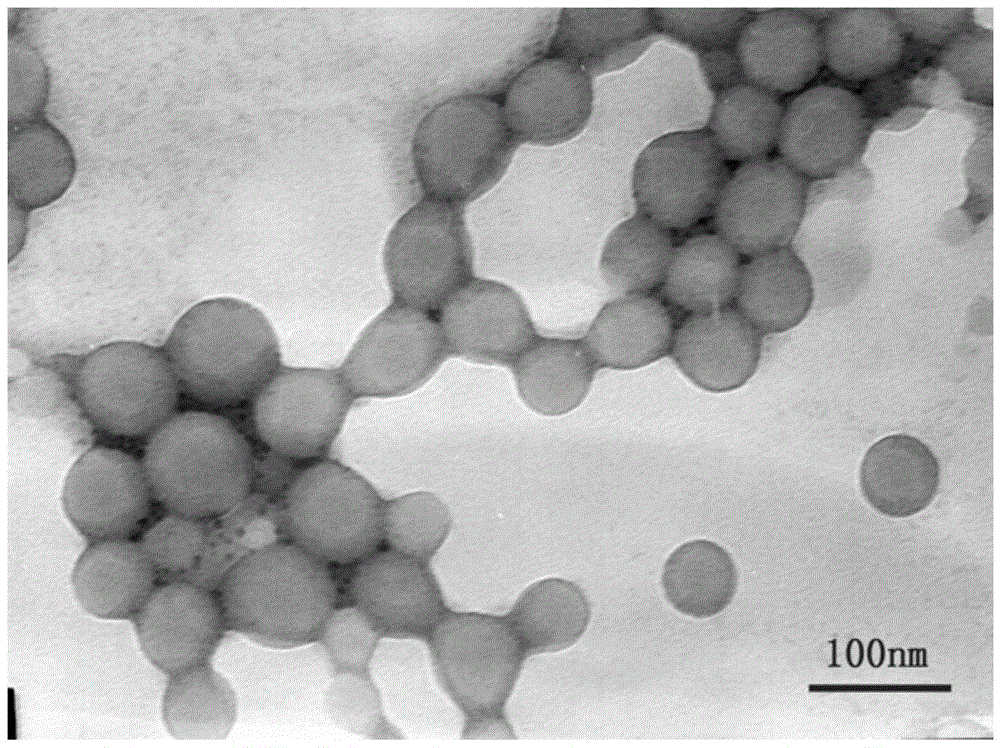

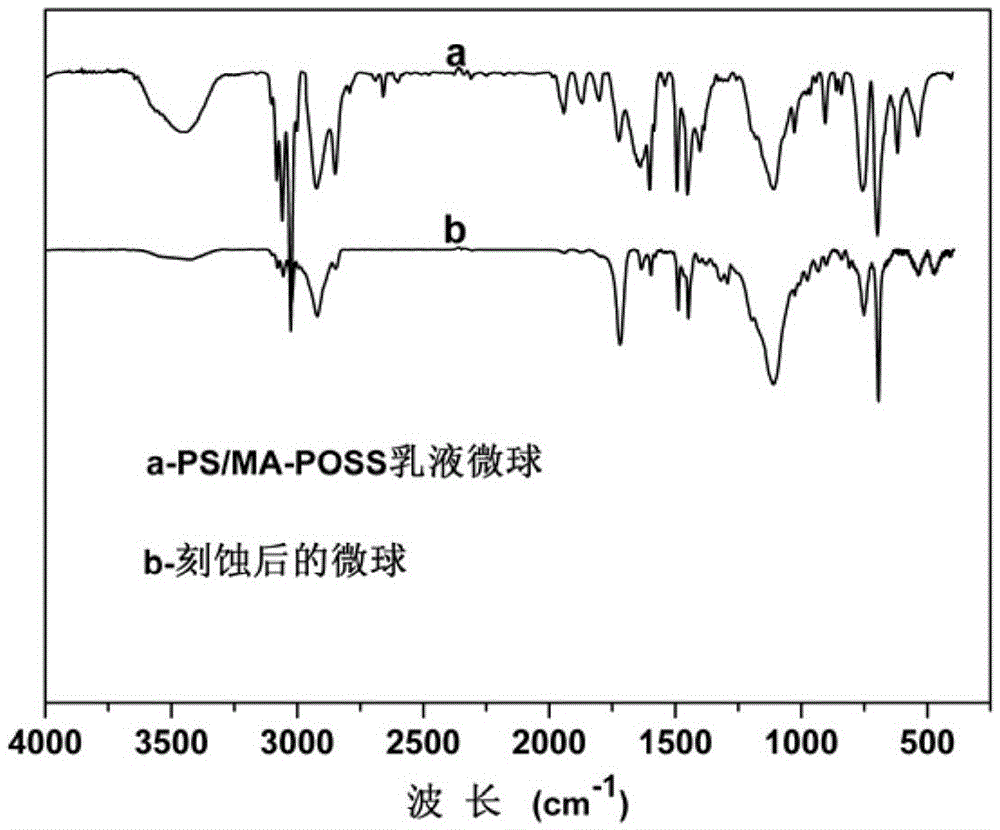

[0038] Embodiment 1: Preparation of hollow structural material based on MA-POSS

[0039] (1) prepare T 8 -MA-POSS content accounted for T 8 -10% T of the total content of MA-POSS and St 8 -MA-POSS Emulsion with Pickering effect.

[0040] (2) Preparation of hollow structural materials

[0041]The emulsion prepared in the above steps was dried in a freeze dryer at a freezing temperature of -55°C and a freezing time of 24 hours. A solid powder was obtained after freeze-drying. Configure a mixed solution with a volume ratio of acetone and cyclohexane of 3:7, and soak the obtained solid powder therein. After 12 hours, it was filtered, and the filtered product was naturally dried to obtain hollow microspheres based on methacryloxycage silsesquioxane in the form of solid powder.

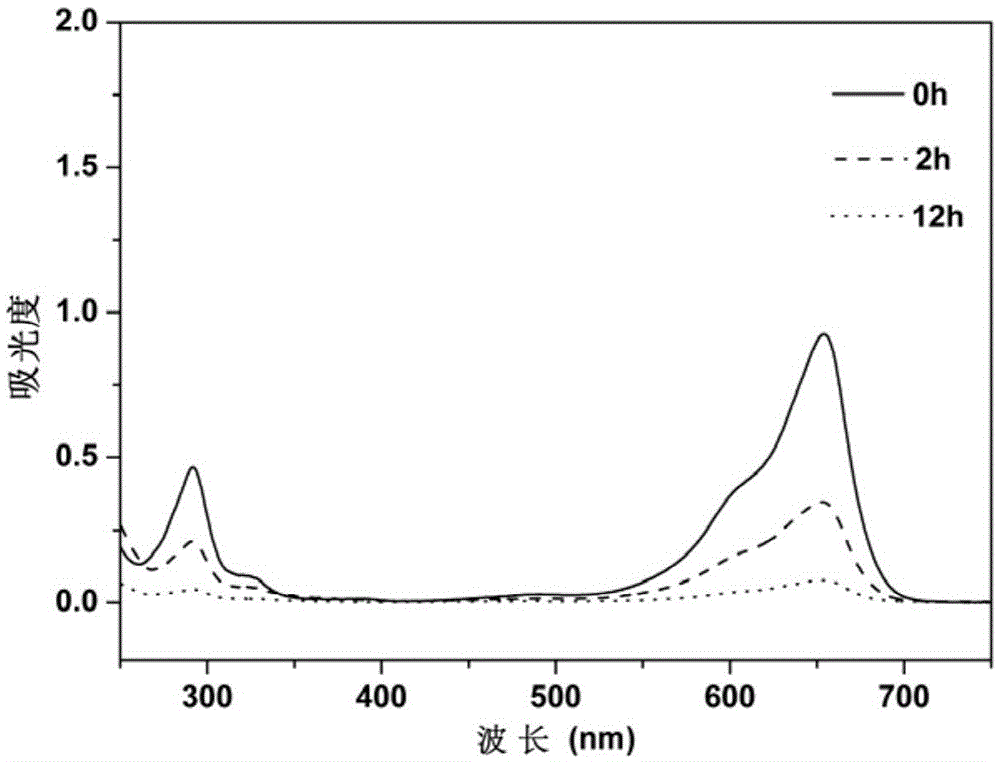

[0042] (3) Dissolve 0.0004g of methylene blue in 20ml of water to obtain a blue liquid, prepare 2 samples, add 0.02g of the above-mentioned hollow microspheres based on methacryloxy cage silsesquioxan...

Embodiment 2

[0044] Embodiment 2: Preparation of hollow structure material based on MA-POSS

[0045] (1) prepare T 8 -MA-POSS content accounted for T 8 -10% T of the total content of MA-POSS and St 8 -MA-POSS Emulsion with Pickering effect.

[0046] (2) Preparation of hollow structural materials

[0047] The emulsion prepared in the above steps was dried in a freeze dryer at a freezing temperature of -55°C and a freezing time of 24 hours. A solid powder was obtained after freeze-drying. Prepare a mixed solution with a volume ratio of acetone and cyclohexane of 5:5, and soak the obtained solid powder therein. After 18 hours, it was filtered, and the filtered product was naturally dried to obtain hollow microspheres based on methacryloxycage silsesquioxane in the form of solid powder.

[0048] (3) Dissolve 0.0004g of methylene blue in 20ml of water to obtain a blue liquid, prepare 2 samples, add 0.02g of the above-mentioned hollow microspheres based on methacryloxy cage silsesquioxane ...

Embodiment 3

[0049] Embodiment 3: preparation of hollow structure material based on MA-POSS

[0050] (1) prepare T 8 -MA-POSS content accounted for T 8 -10% T of the total content of MA-POSS and St 8 -MA-POSS Emulsion with Pickering effect.

[0051] (2) Preparation of hollow structural materials

[0052] The emulsion prepared in the above steps was dried in a freeze dryer at a freezing temperature of -65°C and a freezing time of 24 hours. A solid powder was obtained after freeze-drying. Prepare a mixed solution with a volume ratio of acetone and cyclohexane of 7:3, and soak the obtained solid powder in it. After 24 hours, it was filtered, and the filtered product was naturally dried to obtain hollow microspheres based on methacryloxycage silsesquioxane in the form of solid powder.

[0053] (3) Dissolve 0.0004g of methylene blue in 20ml of water to obtain a blue liquid, prepare 2 samples, add 0.02g of the above-mentioned hollow microspheres based on methacryloxy cage silsesquioxane to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com