Polyarylenesulfidesulfone hollow fiber and flat plate separating membrane and preparation method thereof

A polyarylene sulfide sulfone and fiber separation technology, which is applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of small flux, small pore size, and limited application range, and achieve narrow pore size distribution, The effect of sound structure and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

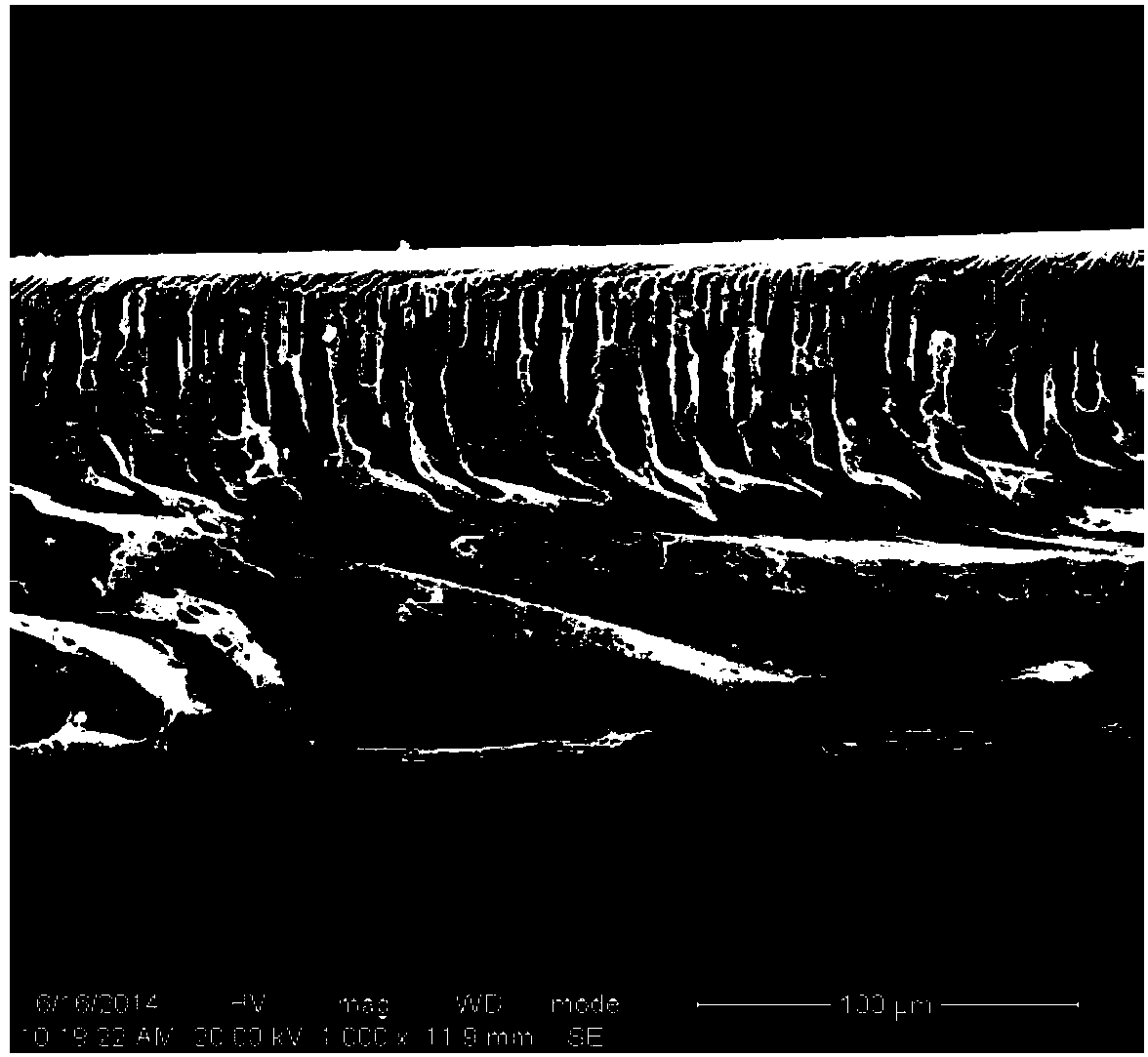

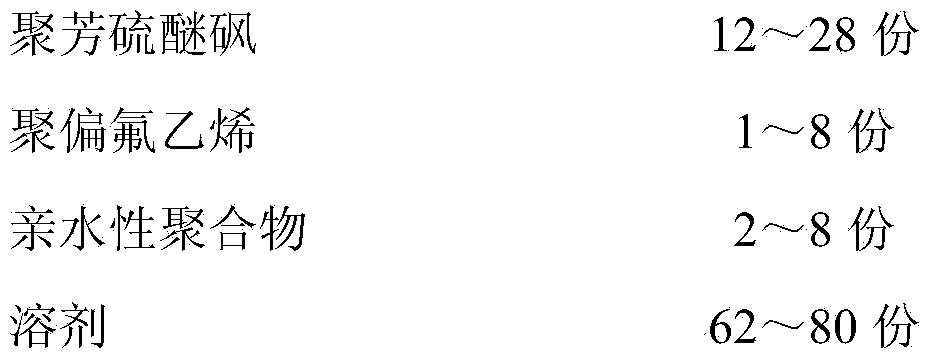

[0031] Example 1: Preparation of polyarylene sulfide sulfone flat membrane.

[0032] Add 12g of polyarylene sulfide sulfone resin, 70g of N-methylpyrrolidone, 8g of polyvinylidene fluoride, 2g of polyvinylpyrrolidone, 6g of polyethylene glycol, and 2g of sodium stearate into a dissolution kettle with a stirrer and a thermometer, Stir and dissolve at a temperature of 120°C, centrifuge at a speed of 5000r / min for 10min in a centrifuge, filter to remove impurities, and stand for 2 hours for defoaming to make a homogeneous stock solution. Scrape the stock solution evenly on a quartz glass plate at a temperature of 20°C with a flat-plate scraper, then immerse the nascent membrane in deionized water at a temperature of 20°C, and the gel will solidify into a polyarylene sulfide sulfone separation membrane. After washing with water, the polyarylene sulfide sulfone separation membrane is soaked in an aqueous solution containing 30% glycerol to preserve pores, and dried to obtain a poly...

Embodiment 2

[0035] Add 16g of polyarylene sulfide sulfone resin, 4g of polyvinylidene fluoride, 68g of N-methylpyrrolidone, 4g of polyvinylpyrrolidone, and 8g of dibutyl phthalate into a dissolution kettle with a stirrer and a thermometer. Stir to dissolve at ℃, centrifuge at a speed of 5000r / min for 10min in a centrifuge, filter to remove impurities, and stand for 4h to make a homogeneous stock solution. Scrape the stock solution evenly on a quartz glass plate with a temperature of 60°C with a flat-plate scraper, and then immerse the nascent membrane in deionized water with a temperature of 60°C, and the gel will solidify into a polyarylene sulfide sulfone separation membrane. After washing with water, the polyarylene sulfide sulfone separation membrane is soaked in an aqueous solution containing 30% glycerol to preserve pores, and dried to obtain a polyarylene sulfide sulfone separation membrane.

[0036] After testing, the flux of the prepared polyarylene sulfide sulfone separation mem...

example 3

[0038] Add 28g of polyarylene sulfide sulfone resin, 1g of polyvinylidene fluoride, 64g of N-methylpyrrolidone, 2g of polyvinylpyrrolidone, and 5g of aluminum oxide into a dissolution kettle equipped with a stirrer and a thermometer, and stir and dissolve at a temperature of 140°C , centrifuge at a speed of 5000r / min for 10min in a centrifuge, filter to remove impurities, and let it stand for 4h for defoaming to make a homogeneous stock solution. Scrape the stock solution evenly on a quartz glass plate at a temperature of 40°C with a flat-plate scraper, then immerse the nascent membrane in deionized water at a temperature of 40°C, and the gel will solidify into a polyarylene sulfide sulfone separation membrane. After washing with water, the polyarylene sulfide sulfone separation membrane is soaked in an aqueous solution containing 30% glycerol to preserve pores, and dried to obtain a polyarylene sulfide sulfone separation membrane.

[0039] After testing, the flux of the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com