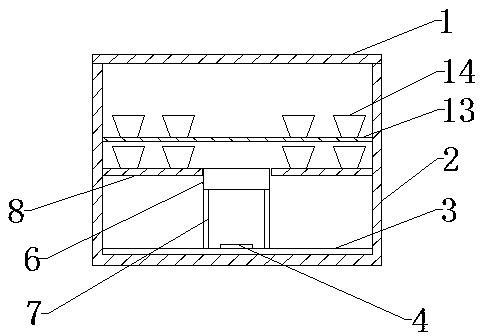

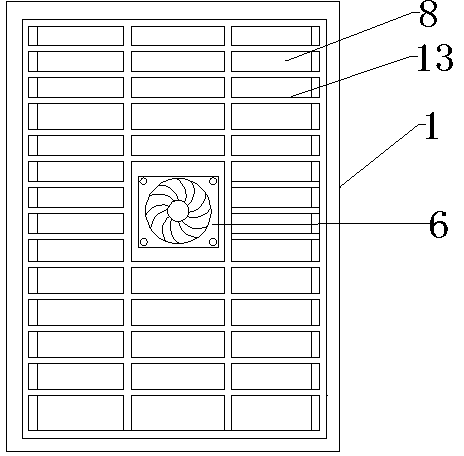

Domestic natto fermentation equipment and fermentation method

A fermenting equipment and household natto technology, which is applied in the field of small and medium-sized domestic natto fermenting equipment, can solve the problems of thin natto moss, bitter taste, too strong ammonia odor, etc., and achieve uniform temperature and moderate hardness , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Put 160g of dry soybeans into 8 cup-shaped natto fermentation containers after pre-processing (cleaning, soaking, steaming, inoculation with Bacillus natto), and put the containers in the household natto fermentation equipment provided by the invention. On the board, turn on the power of the equipment, the controller first controls the electric heater to work at a constant temperature of 38°C-40°C for 7-10 hours; then controls the electric heater to work at a constant temperature of 43°C-45°C for 1-4 hours; controls the electric heater Work at a constant temperature of 46°C-48°C for 4-6 hours; then refrigerate and cook at about 10°C to obtain finished natto. After observation, the mold lawn in the finished product of natto completely covers the surface of the bean grains and is wrinkled; after stirring, the wire drawing is more powerful, smooth, does not hang beads, and the length of the wire drawing reaches 5-6 meters and is not easy to break. After smelling and tasting...

Embodiment 2

[0049] Put 320g soybeans into 16 cup-shaped natto containers after carrying out the pre-processing process (cleaning, soaking, steaming, and inoculation with Bacillus natto), and put the containers in the household natto fermentation equipment provided by the present invention. A shelf is placed above the board (as shown in the figure), and 8 cups are placed on the baffle and on the shelf. Turn on the power of the equipment, the controller first controls the electric heater to work at a constant temperature of 38°C-40°C for 7-10 hours; then controls the electric heater to work at a constant temperature of 43°C-45°C for 1-4 hours; controls the electric heater to work at a constant temperature of 46°C Work at a constant temperature of -48°C for 4-6 hours; then refrigerate and cook at about 10°C to obtain finished natto. It has been observed that the fermentation properties of the natto on the upper layer (that is, on the shelf) and the natto on the lower layer (that is, on the b...

Embodiment 3

[0053] 120g of soybeans are subjected to the pre-processing process (dry soybeans are first crushed into crushed soybeans with a particle size of 2-5mm by a crusher, then cleaned, soaked, steamed, and inoculated with Bacillus natto) and put into 6 cup-shaped sodium In the bean container, put the container on the baffle plate in the household natto fermentation equipment provided by the present invention, switch on the power supply of the equipment, and the controller first controls the electric heater to work at a constant temperature of 38°C-40°C for 7-10 hours; then controls The electric heater works at a constant temperature of 43°C-45°C for 1-4 hours; the electric heater is controlled to work at a constant temperature of 46°C-48°C for 4-6 hours; finally, it is refrigerated and cooked at about 10°C, and the finished product of broken natto can be obtained . After observation, the mold lawn in the finished product of natto completely covers the surface of the bean grains and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com