Unit-type ice storage air conditioning system

An ice-storage air-conditioning, unitary technology, applied in the field of unitary ice-storage air-conditioning systems, can solve problems such as increasing system complexity, reduce heat exchanger volume and transportation energy consumption, improve ice blockage, and reduce energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

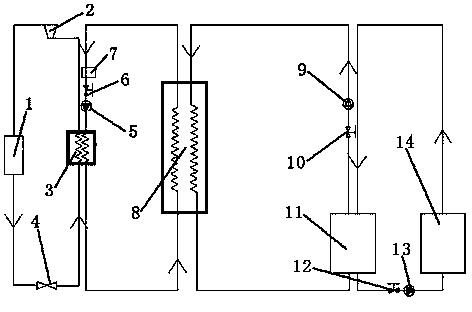

[0017] As shown in the figure, a unitary ice storage air conditioning system is composed of a refrigerant circulation circuit, a refrigerant circulation circuit, an ice making circuit and a refrigeration circuit;

[0018] The refrigerant circulation circuit is a circulation circuit formed by sequentially connecting the fan 1, the throttle valve 4, the heat exchanger 3 and the compressor 2, wherein the refrigerant enters the heat exchanger 3 after being throttled by the throttle valve 4 Absorb the heat released by the brine in the brine circulation loop to raise the temperature, then compress in the compressor 2 and be cooled by the fan 1 to complete the cycle;

[0019] The refrigerant circulation circuit is a circulation circuit formed by connecting the refrigerant storage tank 7, the control valve I6, the centrifugal pump I5, the heat exchanger 3 and the subcooler 8 in sequence, wherein the refrigerant is formed by the refrigerant storage tank 7, and after passing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com