Ultra-thin LED lamp and production technology thereof

A technology of LED lighting and production technology, applied in the field of lighting, can solve problems such as poor light distribution, easy to produce dark shadows, and dark areas with large distances from lamp holders, etc., and achieve sufficient and effective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

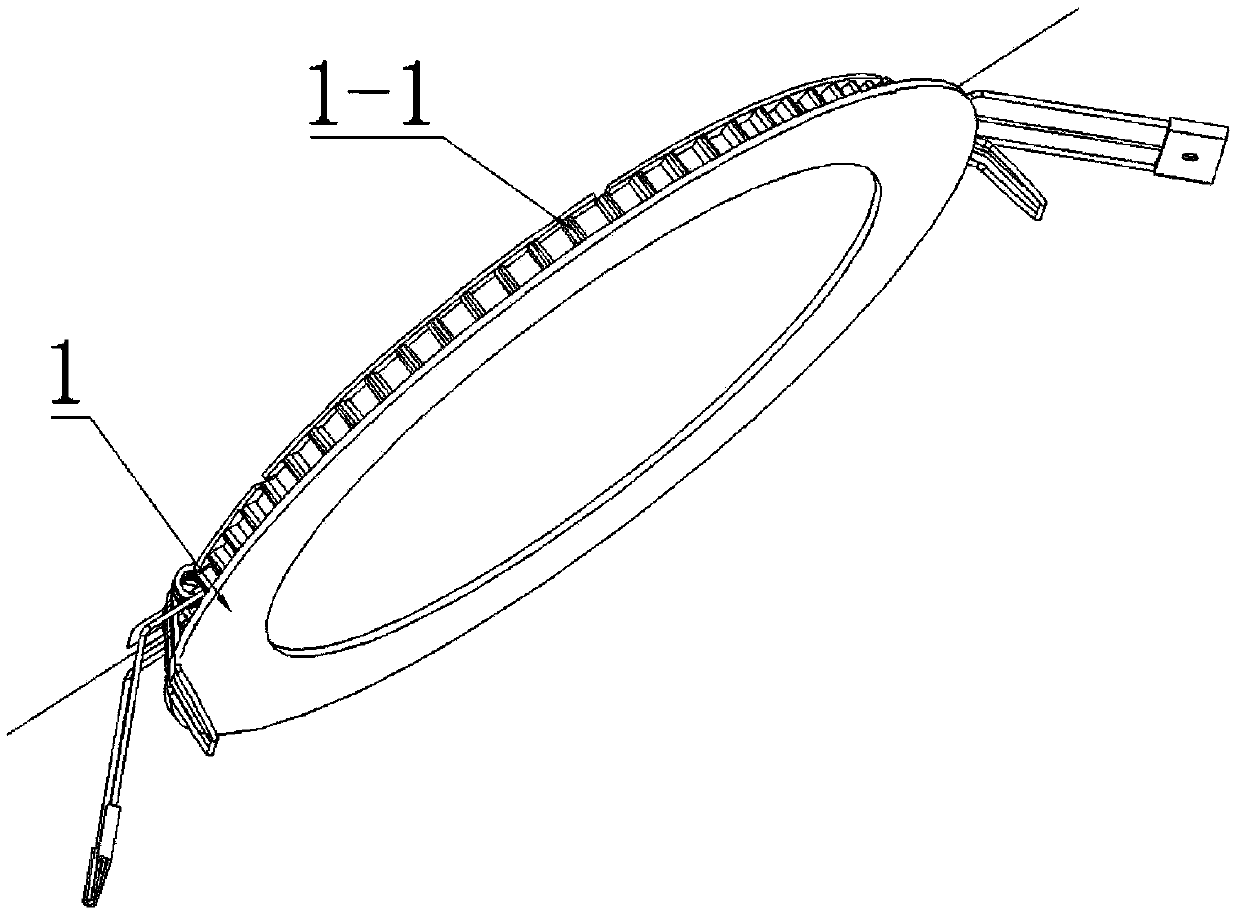

[0041] Such as figure 1 As shown, the present invention is an ultra-thin LED lamp, which includes a heat dissipation lamp body 1 with a light emitting surface, a back cover 2 connected and matched with the heat dissipation lamp body 1, and a back cover 2 arranged between the heat dissipation lamp body 1 and the back cover 2 The diffuser plate 3, the light guide plate 5, and the reflective paper 6 are arranged sequentially from bottom to top. The outer cover of the light guide plate is provided with a flexible LED substrate 4, and LED lamp beads are evenly distributed on the circumference of the flexible LED substrate 4. The light guide plate 5 The front side is a high-gloss mirror surface, and the high-gloss mirror surface is facing the diffusion plate. The reverse side of the light guide plate 5 is a convex-concave grid. The light is evenly mixed with forward reflection and diffuse reflection within the required light distribution range, so that the light can be effectively r...

Embodiment 2

[0053] The difference between this embodiment and the above-mentioned implementation is that the light guide plate and the reflective paper are combined into one, and the specific process is realized: after the mold of the PC light guide plate is injected, the ultra-thin mirror reflective film is pressed on the concave and convex surface of the light guide plate , and its thickness is 0.1mm. Through this production process technology, the light guide plate can complete the effect function of the entire light distribution system, including absorbing enough light from the LED lamp into the light guide plate by relying on the light absorption on the side of the edge; The uneven grid realizes the diffuse reflection of the light emitted to the front; the light overflowed by a very small amount in the diffuse reflection passes through the ultra-thin mirror reflective film on the back of the light guide plate, and after the light is diffusely reflected in the forward direction again, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com