Laser weldable aluminum based composite material and preparation method thereof

An aluminum-based composite material and laser welding technology, which is applied in the field of aluminum-based composite material preparation, can solve the problem that the connection strength and the air tightness of the package cannot meet the requirements, the hot extrusion or hot forging deformation processing cannot be performed, and the substrate and the chip cannot be formed. There are no problems such as mechanical protection, so as to achieve the effects of easy engineering, high utilization of raw materials, and small fluctuations in mechanical performance data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

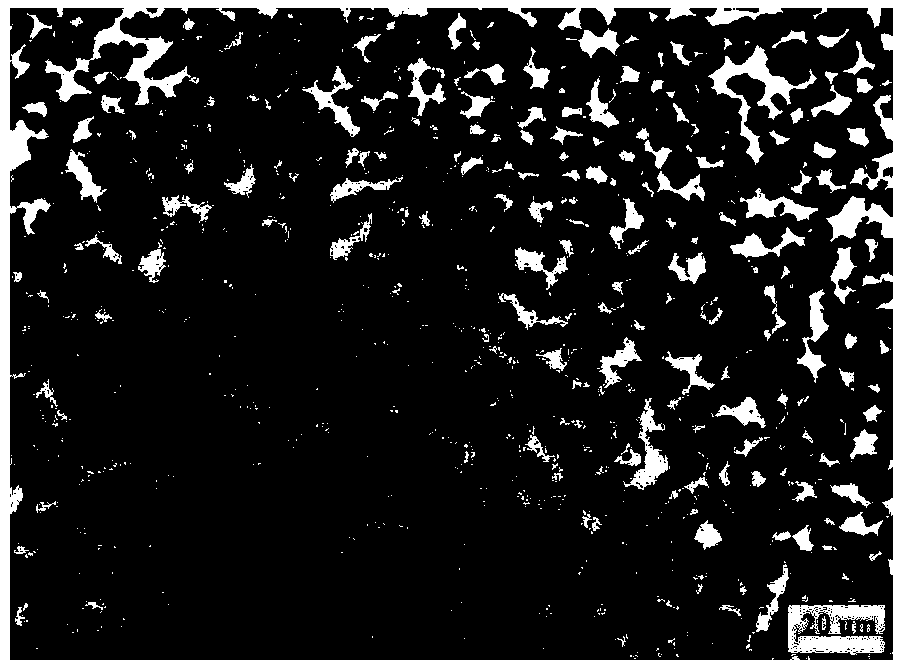

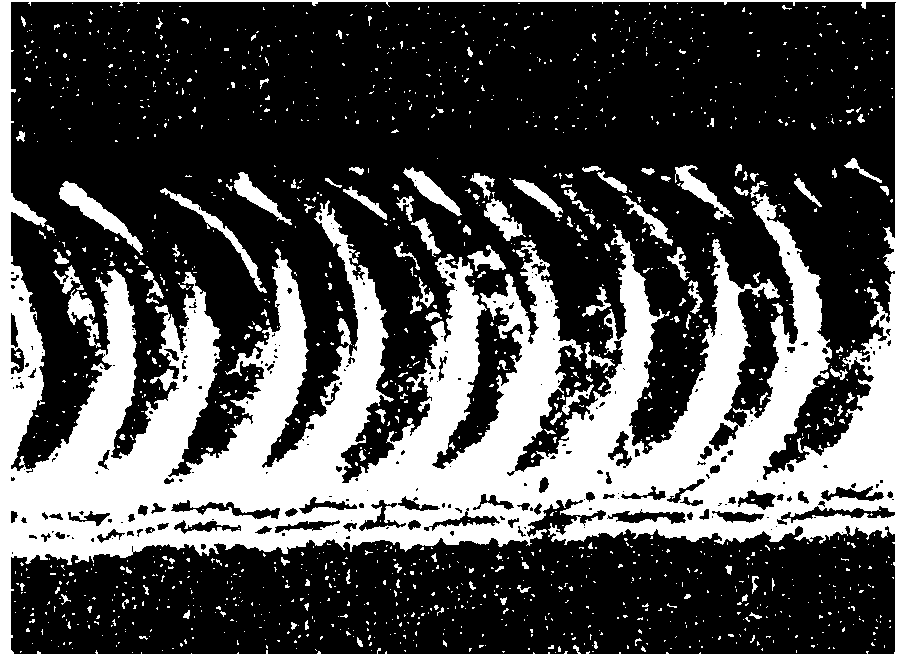

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of 90kg50wt%Si / Al aluminum-based composite material:

[0030] (1) Weigh 45kg of silicon powder with an average particle size of 5.5μm and 45kg of aluminum alloy powder with an average particle size of 4.6μm;

[0031] (2) Put the silicon powder and aluminum alloy powder weighed according to step (1) and 90kg of stainless steel balls into a conical mixing tank for mixing for 30 hours to obtain a uniform Si / Al powder mixture; the speed of the mixer is 50r / min;

[0032] (3) Put the Si / Al powder mixture prepared in step (2) into a rubber sheath with a size of φ380mm×H645mm and cold isostatically press it into a cold isostatic pressed ingot with a relative density of 69%; The static pressure is 200MPa, and the holding time is 15min;

[0033] (4) Put the cold isostatic pressed ingot prepared in step (3) into an aluminum sheath with a size of φ340mm×H580mm for vacuum degassing treatment; the method is as follows: the vacuum value inside the aluminum she...

Embodiment 2

[0036] Embodiment 2: Prepare the aluminum-based composite material of 50kg27wt%Si / Al:

[0037] (1) Weigh 13.5kg of silicon powder with an average particle size of 9.2μm and 36.5kg of aluminum alloy powder with an average particle size of 8.8μm;

[0038] (2) Put the silicon powder and aluminum alloy powder weighed according to step (1) and 40kg of stainless steel balls into a conical mixing tank for mixing for 24 hours to obtain a uniform Si / Al powder mixture; the speed of the mixer is 80r / min;

[0039] (3) Put the Si / Al powder mixture prepared in step (2) into a rubber sheath with a size of φ280mm×H630mm and cold isostatically press it into a cold isostatic pressed billet with a relative density of 74%; cold etc. The static pressure is 150MPa, and the holding time is 10min;

[0040] (4) Put the cold isostatic ingot prepared in step (3) into an aluminum sheath with a size of φ248mm×H570mm for vacuum degassing treatment; the method is as follows: the vacuum value inside the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com