Wrapped profile control degradation agent

A degrading agent and encapsulating technology, applied in drilling compositions, chemical instruments and methods, etc., to achieve the effects of simple process, good anti-corrosion performance and safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The components and weight ratio of the packaged profile control degradation agent are: 1% lipophilic surfactant, 0.5% hydrophilic surfactant, 0.01% stabilizer, 0.2% synergist, 5% degradation agent, organic Solvent 60%, inorganic solvent 33.29%.

[0023] During preparation, the stabilizer is added into the inorganic solvent to fully dissolve, then the degradation agent is added into the stabilizer solution to fully dissolve, and then mixed with other components in the formula evenly.

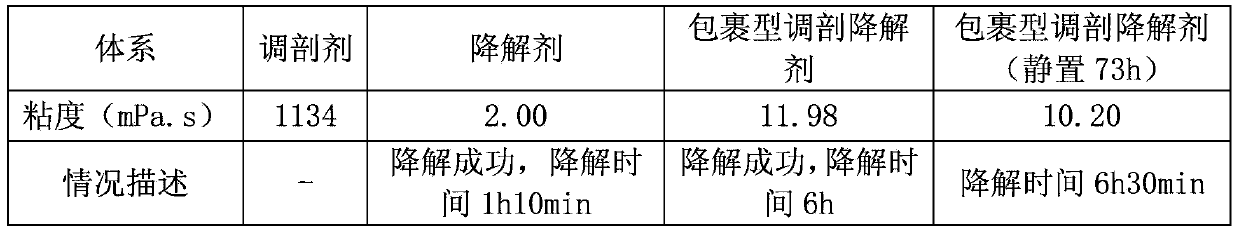

[0024] For the profile control agent used in the field, the above-mentioned prepared degradation agent was used for degradation experiments to investigate the retardation and degradation performance of the packaged profile control degradation agent at formation temperature (60°C). The data are as follows:

[0025] Table 1 Formation temperature (60°C) slow degradation performance of wrapped profile control degradation agent

[0026]

[0027] The packaged profile control degradation agen...

Embodiment 2

[0029] G115-5 is a profile control well in the Ng12 sublayer in the high and shallow northern area. The well started profile control and flooding in April 2007, with a cumulative profile control volume of 12155m 3 . In October 2011, the production was changed, and no liquid was produced after the change. In order to restore the production of the well as soon as possible, the packaged profile control degradation agent 120m was prepared according to the following formula 3 And unwrapped profile control degradation agent 180m 3 . Among them, the packaged profile control degradation agent formula is: 1% lipophilic surfactant; 0.5% hydrophilic surfactant; 0.01% stabilizer; 0.2% synergist; 5% degradation agent; 60% organic solvent; 33.29% inorganic solvent %; Unwrapped profile control degradation agent formula: stabilizer 0.01%; degradation agent 5%. After the degradation is completed, the initial daily liquid production is 14.6m 3 , the yield was stable and the degradation was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com