Addition-type solution-type isolating agent and preparation method thereof

A release agent, solution-based technology, used in inks, household appliances, no pigment coating, etc., can solve the problems of not being able to coat silicon on both sides of paper, having residues, and high energy consumption, and achieving a bright, smooth, low-cost elastic film. Silicon transfer, good substrate bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: The base polymer is made of raw rubber a with a molecular weight of 500,000 and a vinyl mass fraction of 0.7%. 1 And raw rubber a with a molecular weight of 400,000 and a vinyl mass fraction of 0.17%~0.18% 2 and toluene composition.

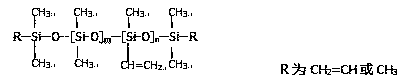

[0031] Raw rubber a 1 The structural formula is:

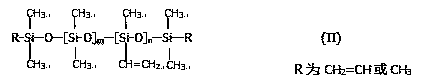

[0032] Raw rubber a 2 The structural formula is:

[0033] .

[0034] To prepare component A:

[0035] Put 259Kg of toluene into a stirred 500L reactor, and then put 37Kg of raw rubber a 1 And 74Kg raw rubber a 2 , and then stir the mixture at room temperature for 3~4 hours to form a uniform solution, then let it stand for 1~2 hours to defoam and cool it down, then put the solution out of the package and store it to get component A.

[0036] To prepare Component B:

[0037] In a 20L stirred tank, the mass fraction of prepared platinum is 0.7%~0.73% platinum-tetramethyldivinyldisiloxane complex, tetramethyldivinyldisiloxane, toluene according to Mix 1,152 grams of plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com