Method for treating low-concentration ammonia-nitrogen wastewater or feed liquid

A low-concentration ammonia nitrogen and treatment method technology, applied in the field of wastewater or feed liquid treatment, can solve the problems of reducing the effect of desorbing ammonia nitrogen, reducing the pH value of the regeneration solution, and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

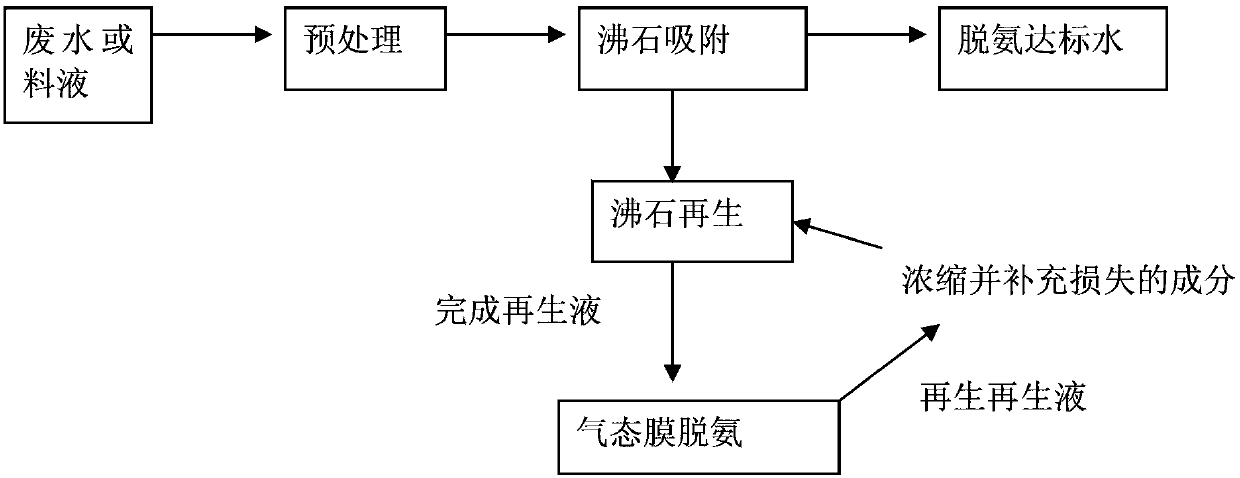

Method used

Image

Examples

Embodiment 1

[0074] Biochemical treatment effluent from a petrochemical plant, pH=6~8, yellow, slightly turbid, water quality is COD Cr 50mg / L, ammonia nitrogen 50mg / L. After ultrafiltration (molecular weight cut-off: 6000MWCO), the waste water is still yellow, but clear and transparent, and the surface tension increases to 68mN / m. The pretreated wastewater enters the natural zeolite adsorption device, and the wastewater flow rate SV is controlled to 30min -1 , after zeolite adsorption treatment, the water quality of the effluent is pH=6~8, yellow, clear, COD Cr 40mg / L, ammonia nitrogen 3.6mg / L.

[0075] Taking 7mg / L as the breakthrough point of zeolite adsorption, when this point is reached, the average ammonia nitrogen value of the overall effluent of the adsorption column is measured to be 4.7mg / L, which meets the national first-class A discharge standard; The solution (density at room temperature is 1.07) after the alkali is adjusted to pH = 12.0 is used to regenerate the zeolite. T...

Embodiment 2

[0077] Biochemical treatment effluent of a municipal sewage treatment plant, pH=6~8, colorless, with suspended solids, water quality is COD Cr 58mg / L, ammonia nitrogen 20mg / L. After microfiltration (average pore size is 0.2μm) and ultrafiltration treatment (molecular weight cut-off is 6000MWCO), the surface tension of wastewater is increased to 68mN / m, and then directly enters the zeolite adsorption device. The flow rate of wastewater is controlled to be 10min-1. After zeolite treatment, The water quality of the effluent is pH=6~8, colorless, clear, COD Cr 40mg / L, ammonia nitrogen 2.5mg / L.

[0078] Taking 8mg / L as the breakthrough point of zeolite adsorption, when this point is reached, the average ammonia nitrogen value of the adsorption column’s overall effluent is measured to be 4.6mg / L, which meets the national first-class A emission standard; use 6%NaCl with pH=11.5 + 5% sodium glycine solution (density 1.06 at room temperature) to regenerate the zeolite, the regenerati...

Embodiment 3

[0080] The biochemical treatment effluent of the sewage treatment plant of an antibiotic production plant, pH=6~8, colorless, with suspended solids, and the water quality is COD Cr 45mg / L, ammonia nitrogen 96mg / L. After microfiltration (average pore size: 0.2μm) and ultrafiltration (molecular weight cut-off: 6000MWCO), the wastewater is treated with surface tension increased to 69mN / m, and then directly enters the zeolite adsorption device, controlling the wastewater flow rate SV to be 10min -1 , after zeolite treatment, the water quality of the effluent is pH=6~8, colorless, clear, COD Cr 41mg / L, ammonia nitrogen 3.0mg / L.

[0081] With 12mg / L as the breakthrough point of zeolite adsorption, when this point is reached, the average ammonia nitrogen value of the overall effluent of the adsorption column is measured to be 4.6mg / L, which meets the national first-class A discharge standard; 20%NaCl with pH=11.5 is used +Na 2 CO 3 The solution (with a density of 1.18) regenerate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com