Preparation method of one-dimensional NiCo2O4 nanorod as supercapacitor material

A supercapacitor, nanorod technology, applied in the fields of nanotechnology, chemical instruments and methods, and nanotechnology for materials and surface science, which can solve the problems of limited commercial production, high reaction temperature, long reaction time, etc. The effect of reducing energy consumption, simplifying the preparation process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

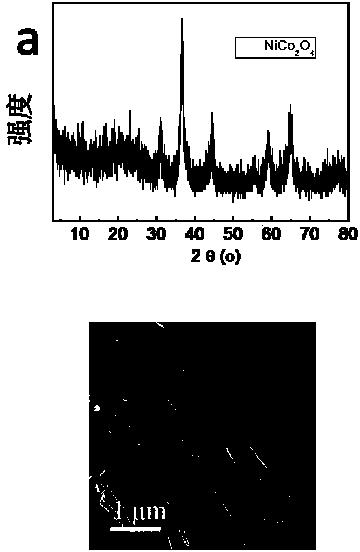

[0023] A supercapacitor material NiCo 2 o 4 The preparation method of one-dimensional nanorod, the steps are as follows:

[0024] 1) Mix 1.5 mL of n-pentanol, 35 mL of cyclohexane and 1 g of cetyltrimethylammonium bromide and stir for 1 hour as the oil phase;

[0025] 2) Add 1.25mL of Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 The mixed solution of O mixed aqueous solution and 2mL oxalic acid aqueous solution is used as the aqueous phase, Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 The molar ratio of O is 1:2, Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 The concentration of O mixed aqueous solution is 0.05 mol / L, and the concentration of oxalic acid aqueous solution is 1 mol / L;

[0026] 3) Under the condition of constantly stirring the oil phase, add the water phase solution drop by drop to form a water-in-oil system, react at room temperature for 2 hours under stirring, and age for 2 hours. Washing three times, then drying the separated product to obtain a prec...

Embodiment 2

[0033] A supercapacitor material NiCo 2 o 4 The preparation method of one-dimensional nanorods, steps 1)-3) are the same as in the examples to obtain the precursor;

[0034] 4) Put 0.9 g of the precursor prepared above in a muffle furnace and heat it to 600 °C at a heating rate of 1 °C / min, and hold it for 3 hours to obtain a black supercapacitor material NiCo 2 o4 Nano stave.

[0035] NiCo 2 o 4 The XRD and SEM images of the one-dimensional nanorods are similar to Example 1.

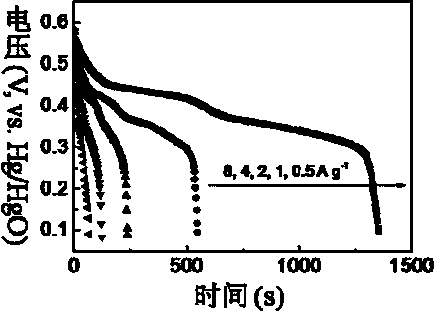

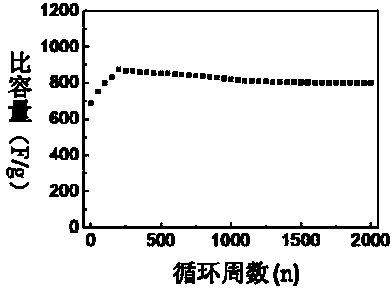

[0036] The prepared supercapacitor material NiCo 2 o 4 One-dimensional nanorods are used to prepare supercapacitor pole pieces, the method is: the prepared NiCo 2 o 4 Nanorods, conductive agent and binder were mixed uniformly according to the mass percentage of 65%: 20%: 15% to obtain a mixture, and 0.9 mL of N-methylpyrrolidone (NMP) was added dropwise to 30 mg of the mixture, ground evenly and evenly coated on the edge On the square nickel foam with a length of 2 cm, the two sides are respect...

Embodiment 3

[0039] A supercapacitor material NiCo 2 o 4 The preparation method of one-dimensional nanorods, steps 1)-3) are the same as in the examples to obtain the precursor;

[0040] 4) Put 1.0 g of the precursor prepared above in a muffle furnace and heat it to 400 °C at a heating rate of 1 °C / min, and keep it warm for 3 hours to obtain a black supercapacitor material NiCo 2 o 4 Nano stave.

[0041] NiCo 2 o 4 The XRD and SEM images of the one-dimensional nanorods are similar to Example 1.

[0042] The prepared supercapacitor material NiCo 2 o 4 One-dimensional nanorods are used to prepare supercapacitor pole pieces, the method is: the prepared NiCo 2 o 4 The nanorods, conductive agent and binder were mixed uniformly according to the mass percentage of 50%: 30%: 20% to obtain a mixture, and 1.4 mL of N-methylpyrrolidone (NMP) was added dropwise to 30 mg of the mixture, ground evenly and evenly coated on the edge On the square nickel foam with a length of 1.5 cm, the two side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com