Preparation method of amorphous BaF2

An amorphous, baf2 technology, applied in the direction of calcium/strontium/barium halide, calcium/strontium/barium fluoride, etc., can solve the problem of no synthetic amorphous structure research report, etc., achieve short synthesis time, repeatable High performance, simple process effect

Inactive Publication Date: 2014-12-17

JILIN NORMAL UNIV

View PDF4 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, so far only BaF 2 The three crystal structures of BaF without using various physical and chemical methods to synthesize the amorphous structure 2 Related Research Reports

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] The present invention will now be described in more detail in conjunction with the examples. Unless otherwise specified, all reagents used are commercially available products without further purification.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Login to View More

Abstract

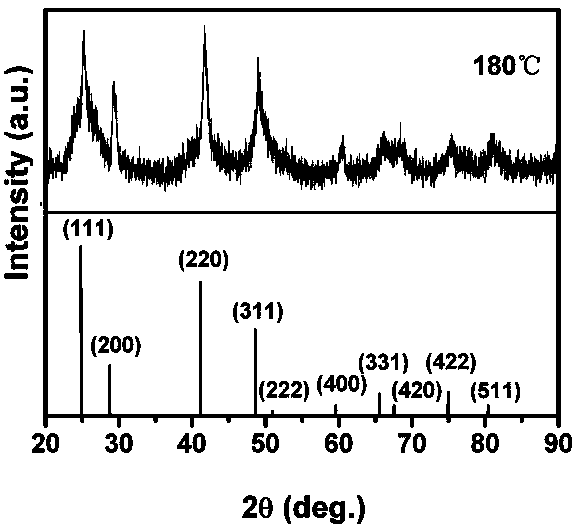

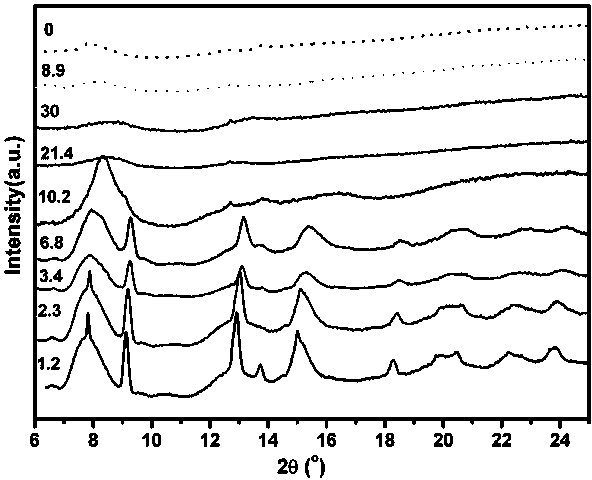

The invention belongs to the technical field of material preparation and relates to a preparation method of amorphous BaF2. The preparation method comprises the following steps of preparing cubic fluorite-structure BaF2 nano-crystal grains as initial raw materials having crystal grain sizes of about 14nm by a solvothermal synthesis method, applying pressure to the material by a diamond opposite-pressing anvil press until the highest pressure is 30GPa so that the cubic fluorite structure of the sample is transformed into an amorphous structure, and releasing the pressure in the diamond opposite-pressing anvil press until the pressure is equal to ordinary pressure so that the amorphous structure of the BaF2 sample is still retained under the ordinary pressure. The initial raw materials have the advantages of simple processes, small crystal grain size, uniform morphology and narrow particle size distribution. The product obtained by high-pressure synthesis has a stable amorphous structure under the ordinary pressure and has high phase purity. The BaF2 material has good optical performances. The novel synthetic material has large application potential in fields of optics and biology.

Description

technical field [0001] The invention belongs to the technical field of material preparation, in particular to an amorphous structure BaF 2 method of preparation. Background technique [0002] BaF 2 It is an important member of alkaline earth metal fluorides and has excellent optical properties. In particular, it is a flash component with an average decay time of less than 1 ns, and is the fastest known inorganic scintillator so far. BaF 2 The scintillation properties of the BaF 2 It has become an ideal high-density luminescent material and is widely used in gamma-ray and elementary particle detectors [1, 2]. In addition, BaF 2 With good ionic conductivity, it has become an important candidate material for high-temperature batteries, fuel cells, chemical filters and sensors [3]. Due to its wide application potential, BaF 2 Has been a hot research material, especially BaF with new crystal structure 2 The synthesis of materials has become a new challenge in the field o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01F11/22

Inventor 王婧姝杨景海李秀艳胡廷静李本淳

Owner JILIN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com