New technology using potash feldspar ore for production of potash, sodium carbonate and alumina

A technology of potassium feldspar and potassium carbonate, applied in the field of non-ferrous metal metallurgy, can solve the problems of high equipment material requirements, harsh dissolution conditions, large material flow, etc., and achieve the effects of low raw material cost, reduced waste water volume, and reduced discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

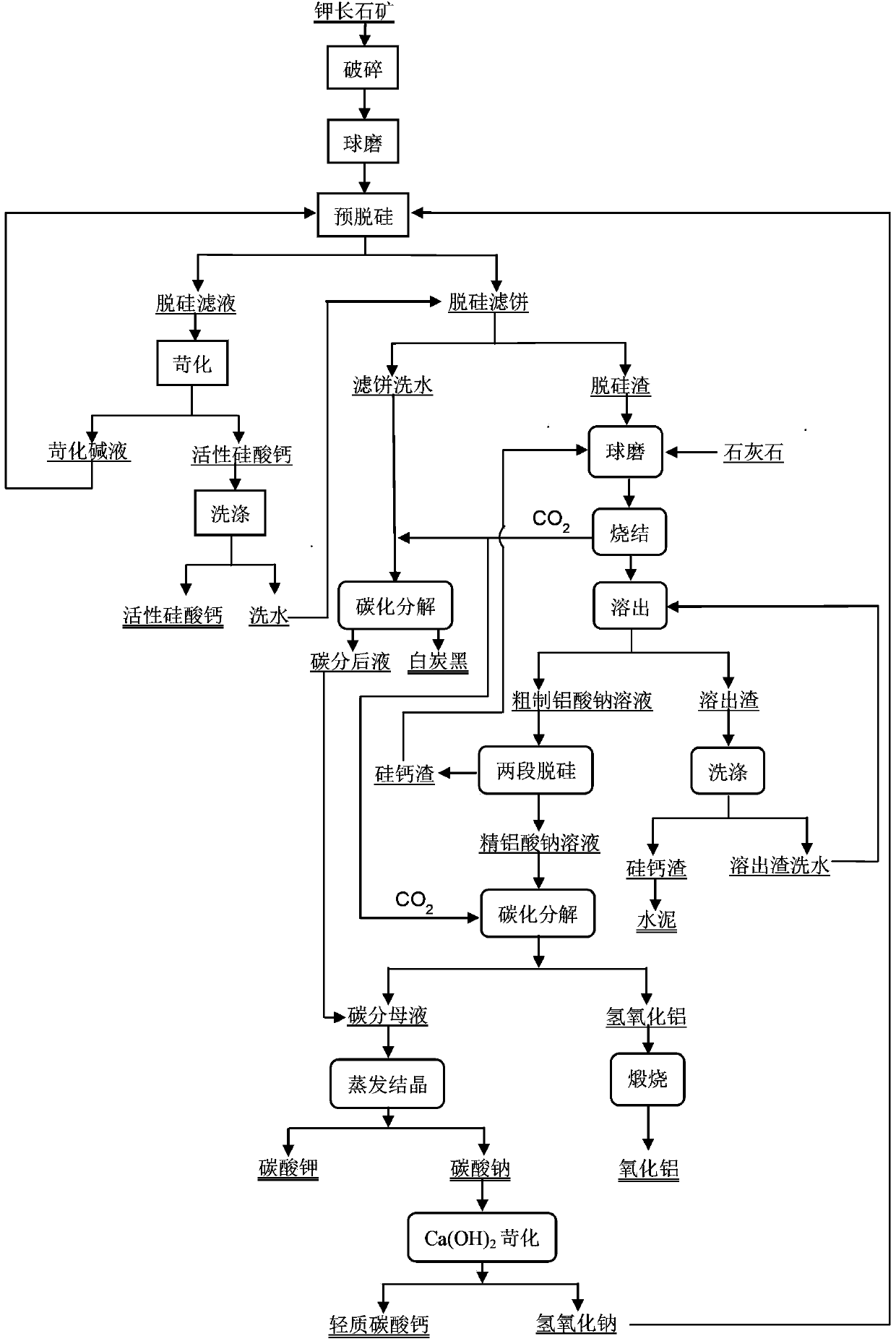

Image

Examples

Embodiment 1

[0057] Potassium feldspar ore is crushed, double-rolled, and ball-milled until the particle size is below 200 mesh, accounting for 90%. Pressurize for pre-desilication, control the linear velocity of leaching and stirring to 1.7m / s, temperature at 170°C, liquid-solid ratio 3:1, time 3h, total alkali R 2 O concentration 250g / l, where Na 2 O concentration 200g / l, K 2 O concentration 50g / l. After filtering, wash with the washing water after washing the active calcium silicate. At this time, the removal rate of silicon in the slag is 42.5%. The desiliconization slag is sintered at a controlled temperature of 1300°C and a time of 0.5h at an alkali ratio of 1 and a calcium ratio of 2. Grind the clinker to less than 60 mesh, liquid-solid ratio 2:1, temperature 70°C, time 20min, carry out clinker dissolution, filter, dissolve slag slurry and wash, dry and send samples. At this time, the dissolution rate of aluminum was 86.5%, and the dissolution rate of potassium and sodium was 92...

Embodiment 2

[0061] Potassium feldspar ore is crushed, double-rolled, and ball-milled until the particle size is below 200 mesh, accounting for 95%. Desiliconization test was carried out under pressure, the leaching stirring line speed was controlled to 1.6m / s, the temperature was 180°C, the liquid-solid ratio was 4:1, the time was 3h, the total alkali R 2 O concentration 220g / l, where Na 2 O concentration 200g / l, K 2 O concentration 20g / l. After filtering, wash with the washing water after washing the active calcium silicate. At this time, the removal rate of silicon in slag is 38.6%. The desiliconization slag is sintered according to the alkali ratio of 1.05, calcium ratio of 1.95, controlled temperature of 1250°C and time of 0.5h. Grind the clinker to less than 60 meshes, dissolve the clinker at a liquid-to-solid ratio of 3:1, temperature 80°C, and time 40 minutes, filter, dissolve the slag into pulp and wash, dry and send samples. At this time, the dissolution rate of aluminum was ...

Embodiment 3

[0065] Potassium feldspar ore is crushed, double-rolled, and ball-milled until the particle size is below 200 mesh, accounting for 85%. Desiliconization test was carried out under pressure, the leaching stirring line speed was controlled to 1.6m / s, the temperature was 190°C, the liquid-solid ratio was 2:1, the time was 4h, the total alkali R 2 O concentration 240g / l, where Na 2 O concentration 200g / l, K 2 O concentration 40g / l. After filtering, wash with the washing water after washing the active calcium silicate. At this time, the removal rate of silicon in the slag is 46.6%. The desiliconization slag is sintered according to the alkali ratio of 0.95, calcium ratio of 1.9, controlled temperature of 1230°C and time of 0.5h. Grind the clinker to less than 60 meshes, dissolve the clinker at a liquid-solid ratio of 3:1, temperature 80°C, and time 40 minutes, filter, and slurry the dissolved residue, then dry and send samples. At this time, the dissolution rate of aluminum was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com