Molecular sensor based on virtual buried nanowire

A molecular and surface-sensing technology, applied in instruments, analytical materials, scientific instruments, etc., can solve the problems of commercial gas sensors being infeasible, cost increasing, and incapable of adapting to high-capacity manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0110] Reference is now made to the following examples, which together with the foregoing description illustrate some embodiments of the invention in a non-limiting manner.

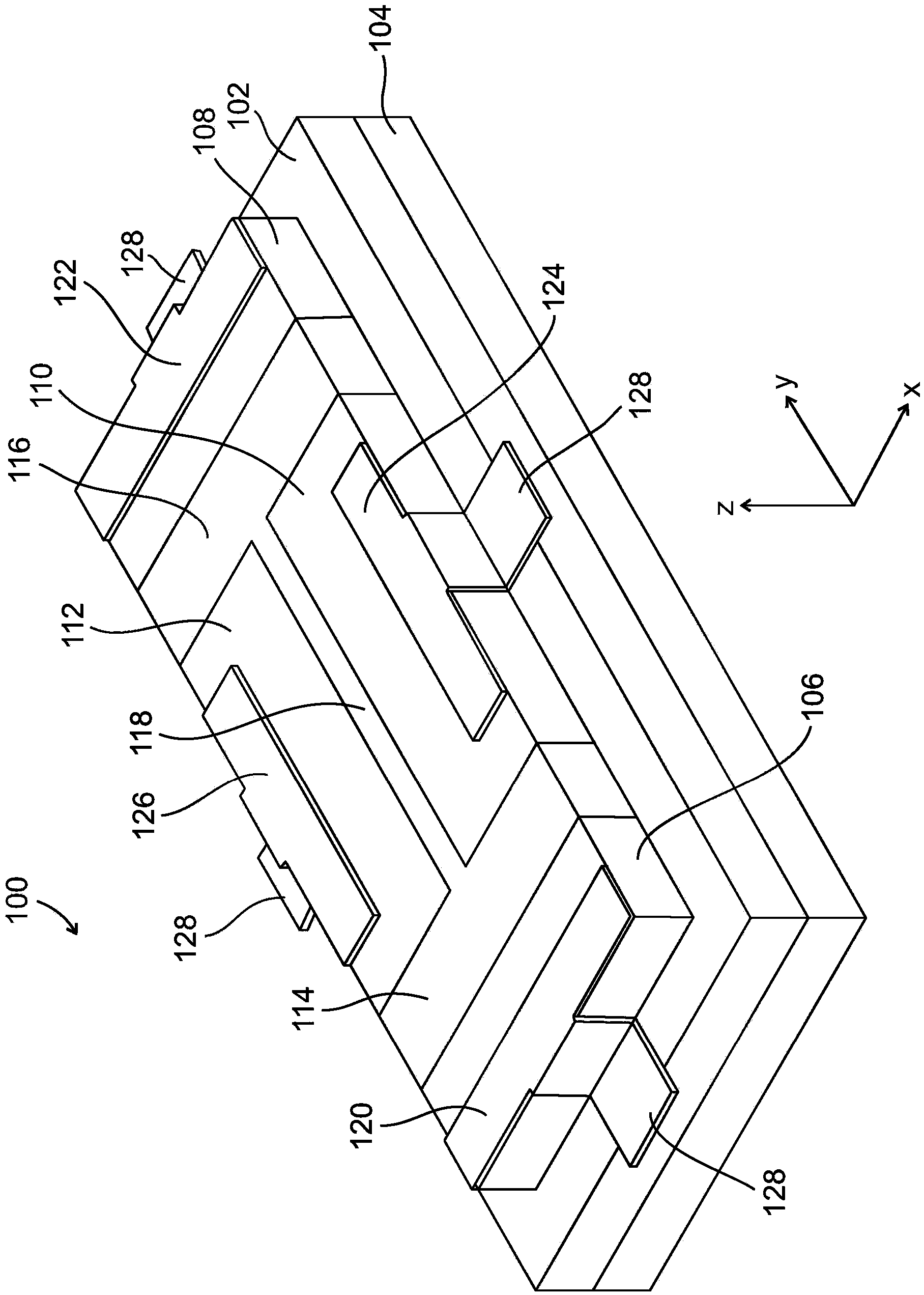

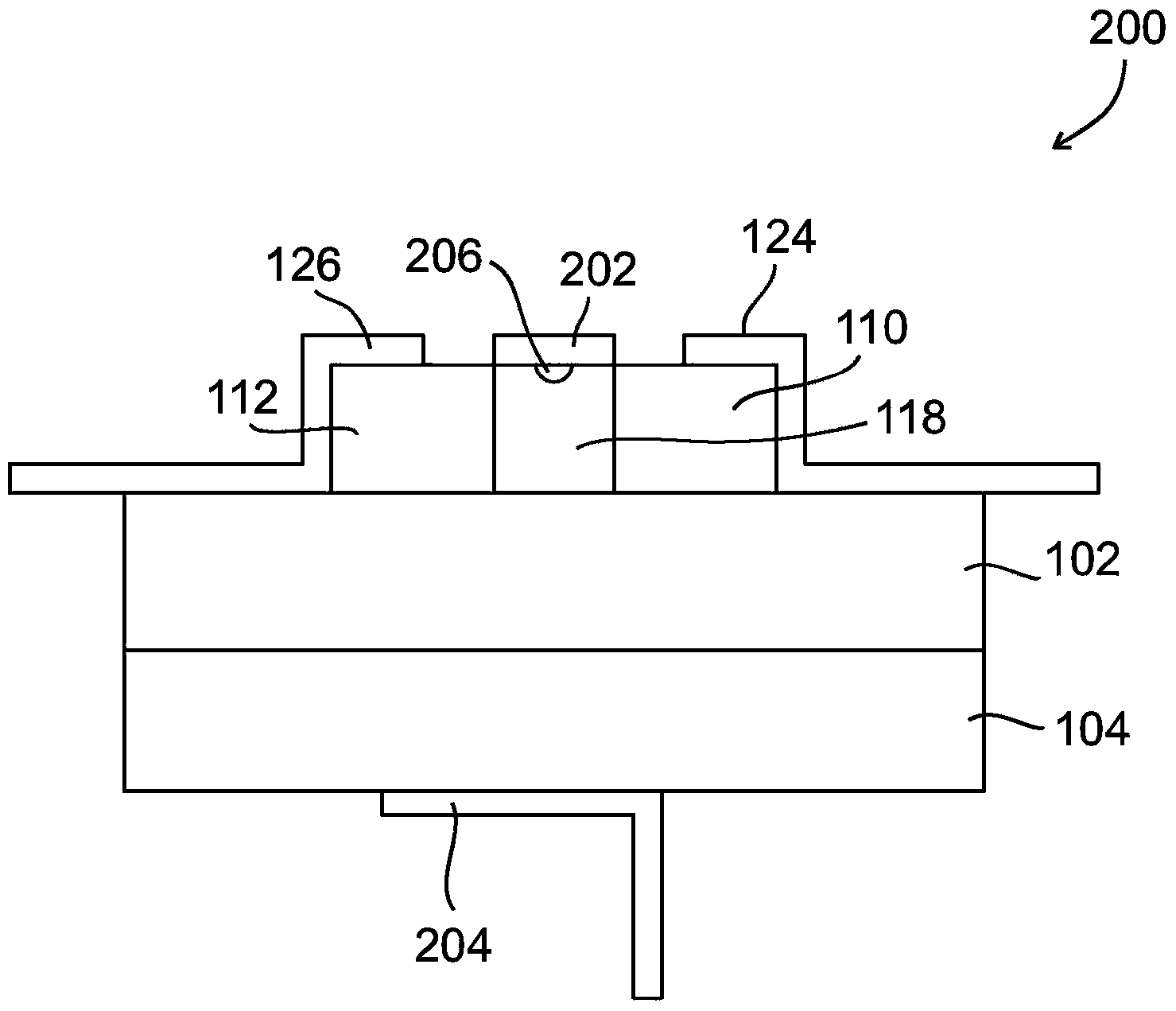

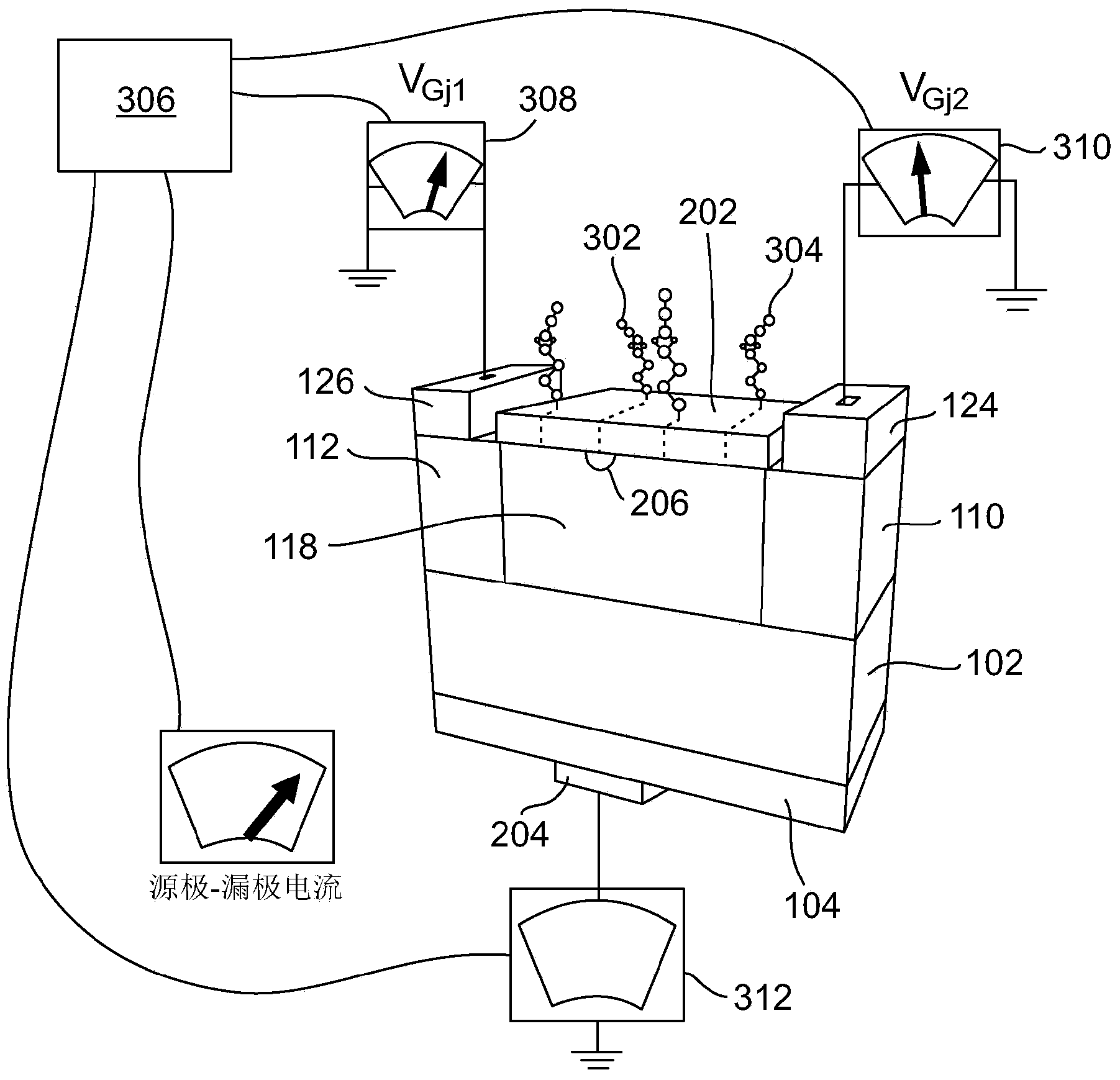

[0111] The universal silicon configuration of virtual embedded nanowire gas sensors is experimentally confirmed using bioassays. In this experiment, the thickness of the SOI layer is 260nm, which has 1.6x10 14 cm -3 doped with boron so that the SOI layer has a resistivity of 13 to 22 Ωcm. The thickness of the buried oxide is 1 μm. SiO 2 The thickness of the gate dielectric is 5 nm. The active region, including the wider portions adjacent to the source and drain regions, is doped with a 1.6x10 17 cm -3 range of arsenic. The source and drain regions are doped with a 5x10 19 cm -3 range of arsenic, and the lateral gate region is doped with a 5x10 19 cm -3 range of boron. The distance from the source region to the drain region is 10 μm, and the length of the active region defined as the length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com