Method and apparatus for adhesive bonding in an aqueous medium

一种粘合剂、亲水聚合物的技术,应用在海藻酸粘合剂、非高分子粘合剂添加剂、胶粘剂等方向,能够解决整合困难、没有显示性能、物理和化学性质改变等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

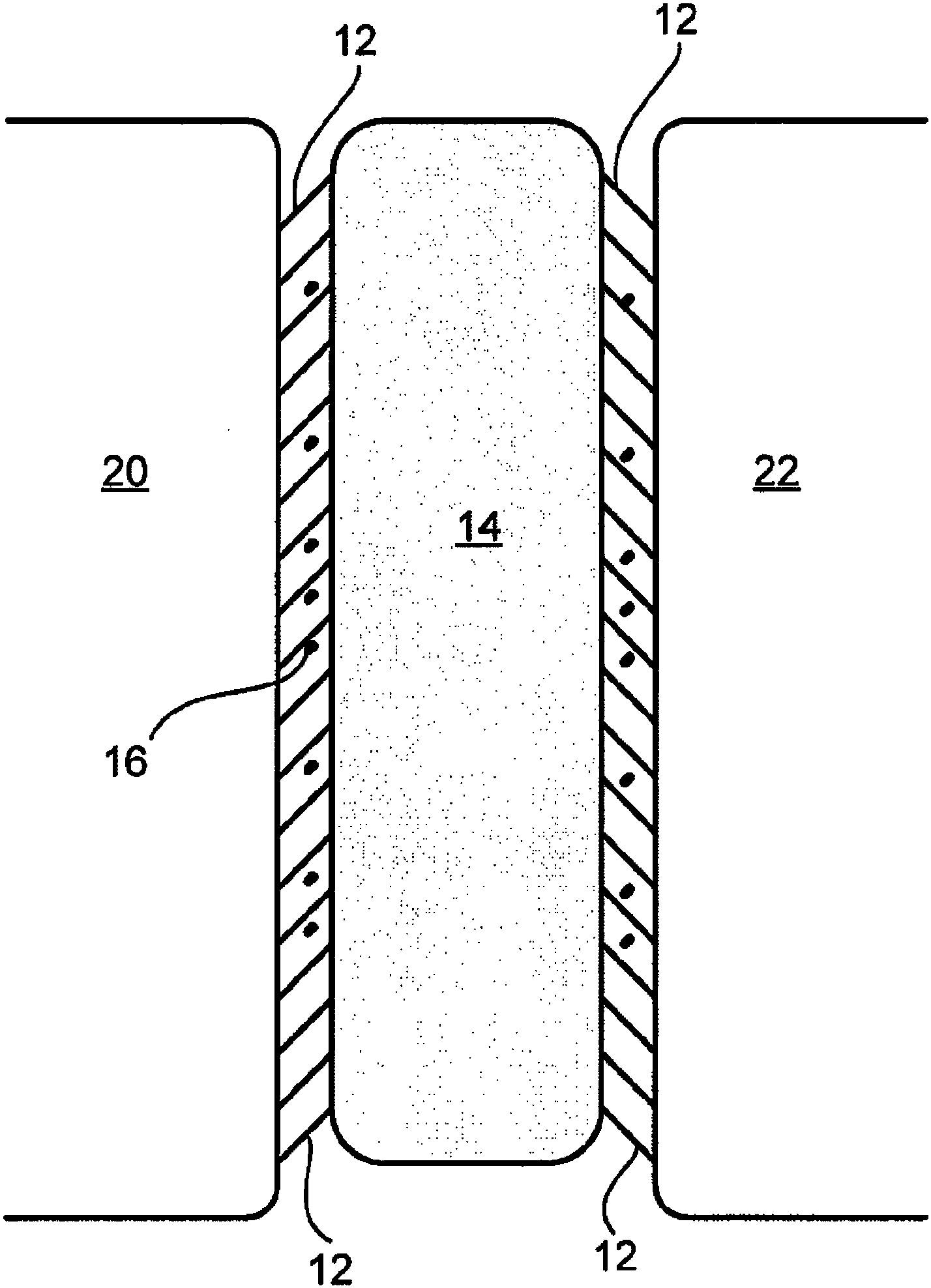

[0055] In the first experiment or fabrication, hydrophilic adhesive molecules such as concentrated dopamine hydrochloride solution and adhesive molecules such as dopamine hydrochloride were mixed with ferric nitrate, tris(hydroxymethyl)aminomethane (Tris) and A water-oxidant mixture is injected under water as the interface between a soft polydimethylsiloxane (soft like human tissue) as the first surface and a hard glass substrate as the second surface. Despite a large mismatch in the elasticity of the substrates, an improvement in interfacial adhesion was observed. Improvements in this interface may facilitate applications such as immobilizing implants in vivo.

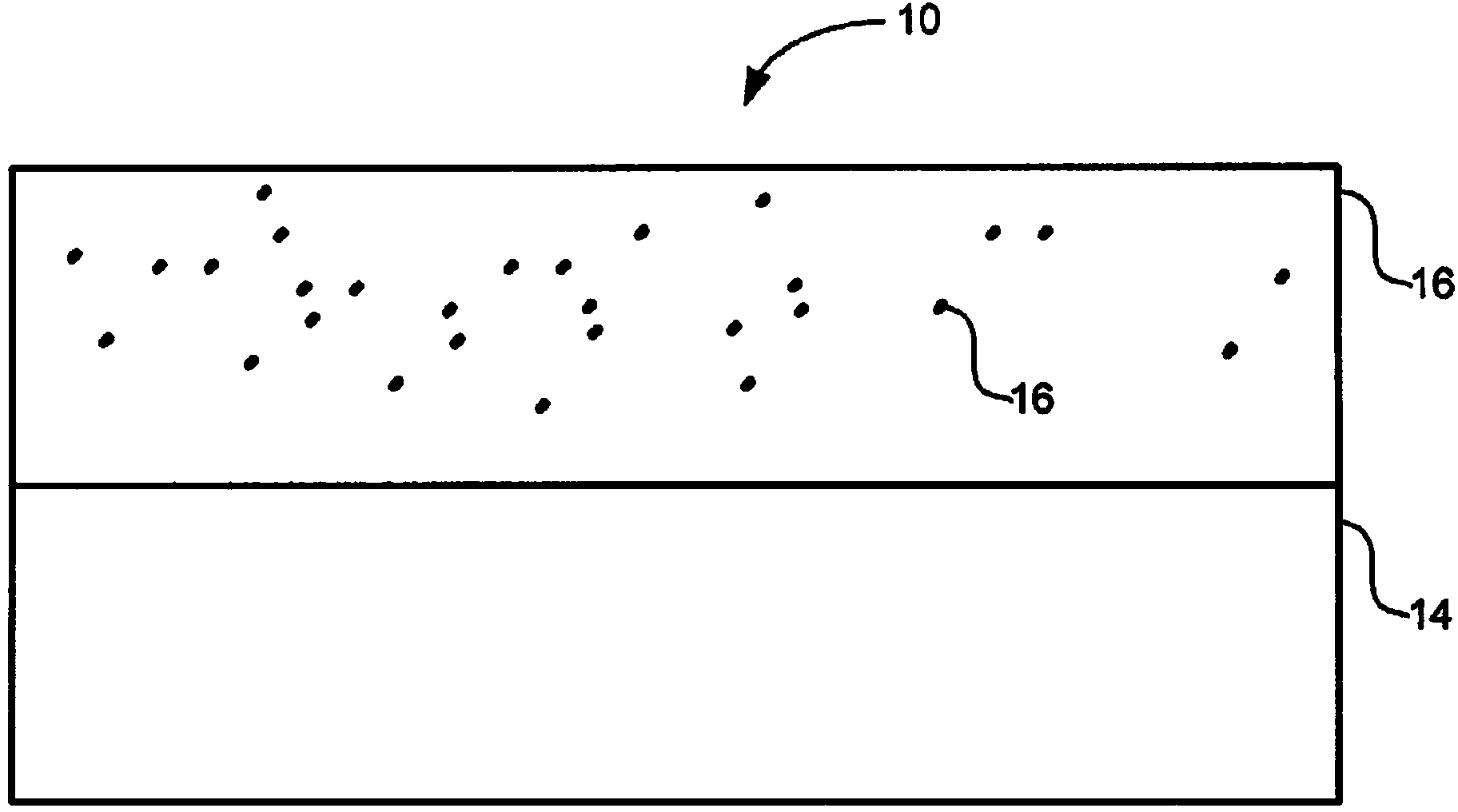

[0056] More specifically, the adhesive strength of polydopamine was investigated by in situ polymerizing dopamine between two interfaces underwater. Inject and sandwich 0.1 mL of concentrated dopamine solution at a molar ratio of dopamine to water of 1:8 between hemispherical soft PDMS tips and flat rigid microscope ...

Embodiment 2

[0059] In another experiment or fabrication, the adhesive material provides a means of bonding and joining two similar or dissimilar materials underwater. In this embodiment, the binder material comprises two different components comprising binder molecules, a hydrophilic polymer and at least one oxidizing agent. The first component is a mixture of four chemicals: dopamine hydrochloride (hydrophilic binder molecule), ferric nitrate (oxidant), tris(hydroxymethyl)aminomethane (Tris) (oxidant), and water (oxidant). The second component is a solution of sodium alginate (hydrophilic polymer) that forms a hydrogel network with the first component when mixed. In the course of the experiments, the binding or joining takes place by successive injections of the first component and the second component at the junction (between the two surfaces to be adhered) in water. The surfaces are gently squeezed together after each injection to evenly distribute the adhesive material at and across ...

Embodiment 3

[0066] In another experiment or fabrication, it was shown that the adhesive material can maintain improved performance and suitable adaptability to meet the needs of various applications. In this experiment, the adhesive material was able to react at different pH and temperature (in the range of 4 to 10 and in the range of 20°C to 40°C, respectively) and on different substrates (such as polyethylene terephthalate) Carried on. The formulation of the adhesive material, in this embodiment, is considered variable such that its adhesive components (hydrophilic adhesive molecules, hydrophilic polymer and oxidizing agent) can be replaced by different hydrophilic polymers (such as poly(4-styrene sodium sulfonate)) and different oxidizing agents (such as ammonium persulfate and calcium ions) instead. The results of the tensile test show that the curing time is 2 hours and has a 100mm 2 The bonding strength of the contact area generally exceeds 0.5kg or 50kPa in these different applic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com