Synergistic silica scale control

A silica scale, water-based system technology, applied in water treatment parameter control, descaling and water softening, chemical instruments and methods, etc., can solve problems such as low effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

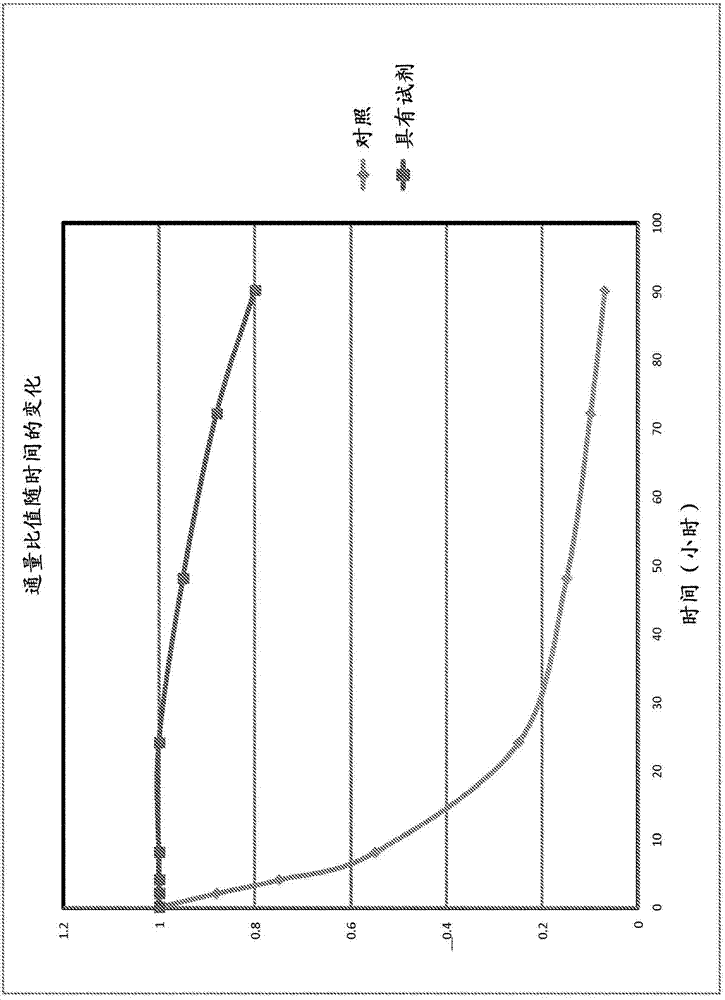

Image

Examples

Embodiment 1

[0064] Combination 1 is a 50:50 combination of a phosphinocarboxylic acid polymer with a weight average molecular weight of 4500 g / mol and tetrasodium ethylenediaminetetraacetic acid.

Embodiment 2

[0066] Combination 2 is a 50:50 combination of a polymerization product of acrylic acid and maleic acid with phosphono end groups and a weight average molecular weight of 2000 g / mol and tetrasodium edetate.

[0067] Two other comparative blends were tested which showed no synergistic performance as follows -

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com