Lithium-ion battery, preparation method thereof, and charging method of lithium-ion battery

A lithium-ion battery and electrolyte technology, applied in secondary battery charging/discharging, electrolyte battery manufacturing, secondary batteries, etc., can solve the problem of restricting the application of high-energy density batteries, affecting the cycle performance of lithium-ion batteries, and affecting lithium-ion batteries Liquid retention and other issues to achieve the effect of improving cycle performance, reducing polarization, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

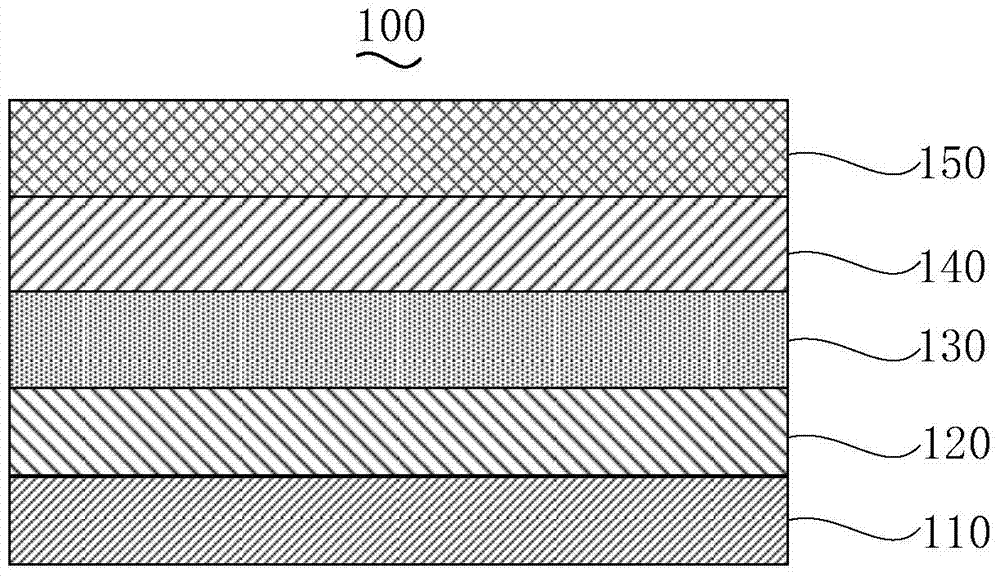

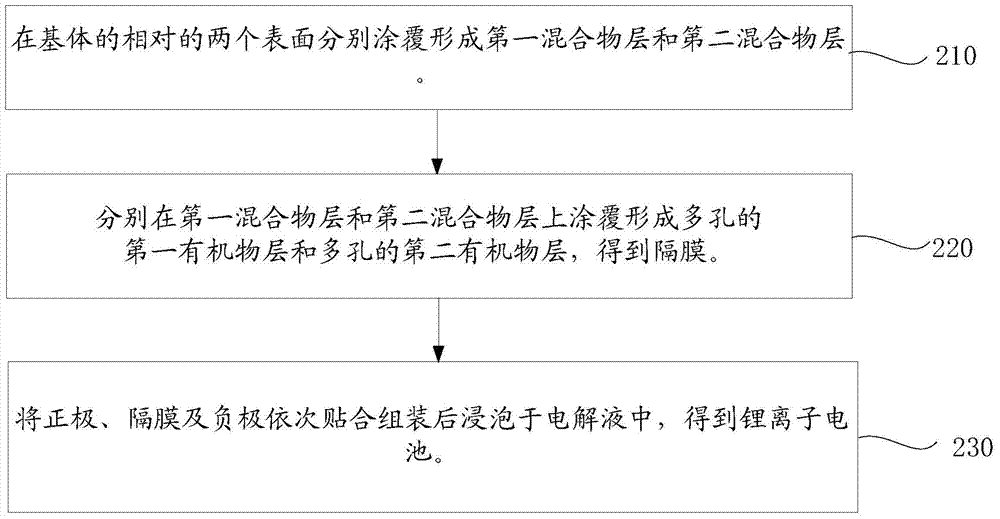

[0063] like figure 2 As shown, the preparation method of a lithium-ion battery in one embodiment can be used to prepare the above-mentioned lithium-ion battery, and the preparation method of the lithium-ion battery includes the following steps:

[0064] Step S210: coating the two opposite surfaces of the substrate to form a first mixture layer and a second mixture layer respectively. Wherein, the material of the first mixture layer and the second mixture layer is a mixture of polyvinylidene fluoride and oxide, and the oxide is selected from at least one of alumina, zirconia and titanium dioxide.

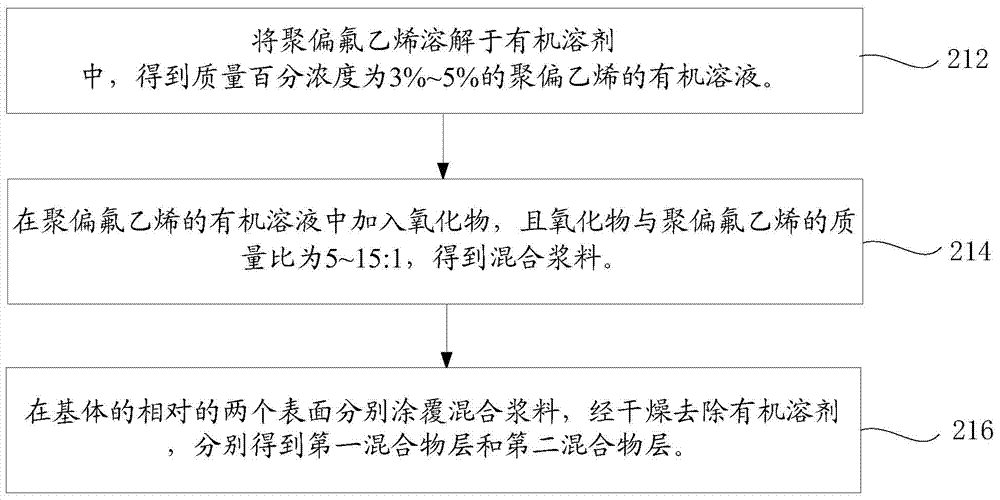

[0065] Further, such as image 3 As shown, the steps of coating and forming the first mixture layer and the second mixture layer on the two opposite surfaces of the substrate are specifically:

[0066] Step S212: dissolving polyvinylidene fluoride in an organic solvent to obtain an organic solution of polyvinylidene fluoride with a mass percent concentration of 3%-5%. Wherein, th...

Embodiment 1

[0099] The preparation steps of the lithium ion battery of the present embodiment are as follows:

[0100] (1) Preparation of positive electrode:

[0101] First, prepare modified lithium cobaltate: dissolve cobalt nitrate, lithium nitrate and magnesium nitrate in an aqueous solution with a mass percent concentration of 50% citric acid according to a mass ratio of 1:1:0.2 to obtain a sol; then place the above sol in Dry at 100°C to obtain a gel, which is ground and sintered at 860°C for 12 hours to obtain magnesium-doped lithium cobaltate; then dissolve polyacrylic acid in deionized water to obtain an aqueous solution of polyacrylic acid. Magnesium carbonate is added in the aqueous solution, obtains transparent solution, and wherein, the mol ratio of the carboxyl in the transparent solution and the magnesium element in magnesium carbonate is 2.5:1; The molar ratio of the elements is 1:0.004, adding magnesium-doped lithium cobaltate to the transparent solution to obtain a slurr...

Embodiment 2

[0117] The preparation steps of the lithium ion battery of the present embodiment are as follows:

[0118] (1) Preparation of positive electrode:

[0119] First, prepare modified lithium cobaltate: dissolve cobalt nitrate, lithium nitrate and aluminum nitrate in an aqueous solution with a mass percentage concentration of 50% citric acid according to a mass ratio of 1:1:0.3 to obtain a sol; then put the above sol in Dry at 110°C to obtain a gel. After grinding, sinter at 850°C for 11 hours to obtain aluminum-doped lithium cobaltate; then dissolve polyacrylic acid in deionized water to obtain an aqueous solution of polyacrylic acid. In the polyacrylic acid Add zirconium carbonate in the aqueous solution, obtain transparent solution, wherein, the molar ratio of the carboxyl group in the transparent solution and the zirconium element in zirconium carbonate is 2.4:1; The molar ratio of the elements is 1:0.003, adding aluminum-doped lithium cobaltate to the transparent solution to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com