Preparation and application of a kind of microbial fuel cell cathode catalyst

A fuel cell cathode and catalyst technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve problems such as poor conductivity and complex application, and achieve the effects of low cost, simple process and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add potassium permanganate to deionized water, stir to form a uniform solution with a concentration of 0.3mol / L of potassium permanganate, then add manganese sulfate and stir to form a uniform mixed solution, the mass ratio of potassium permanganate and manganese sulfate 5:2, then transfer the above mixed solution to a high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, react at a temperature of 140°C for 2 hours, then cool to room temperature, filter, and use deionized Rinse with water until neutral, and dry in air at 100°C to obtain manganese dioxide nanoflowers. Subsequently, 0.15 g of the above-mentioned manganese dioxide nanoflowers were placed in 60 ml of 0.01 mol / LH 2 SO 4 In the solution, ultrasonically suspend, quickly add 100μL pyrrole monomer and 40ml0.01mol / LH 2 SO 4 The mixture of the solution was placed in an ice bath and stirred for 3 hours, then filtered, and the filtered solid deionized water and ethanol were alternately ...

Embodiment 2

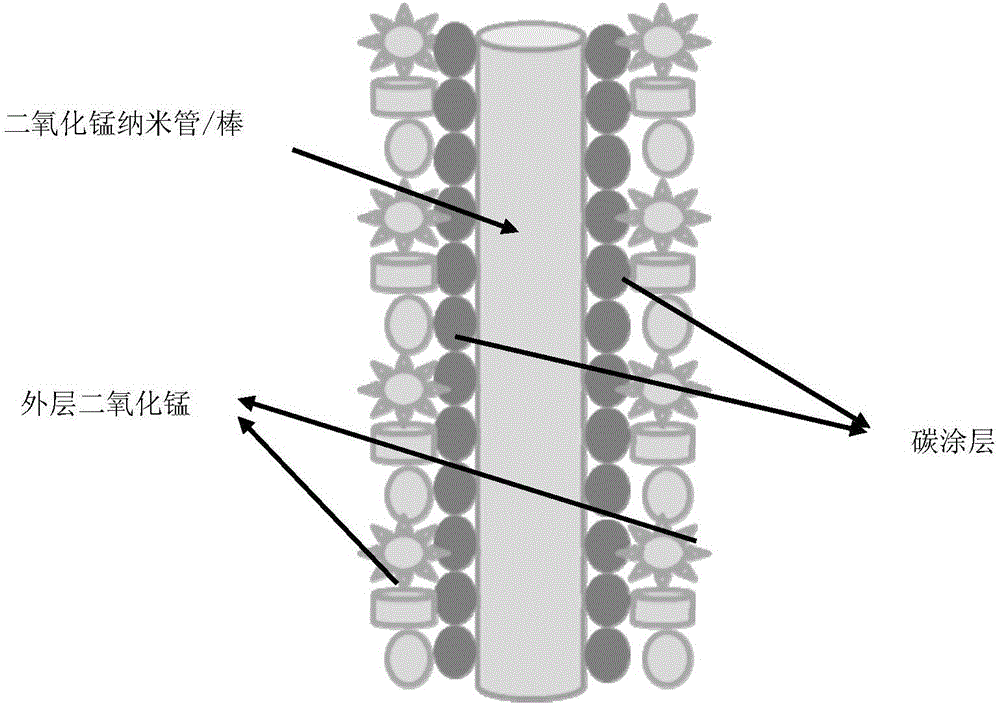

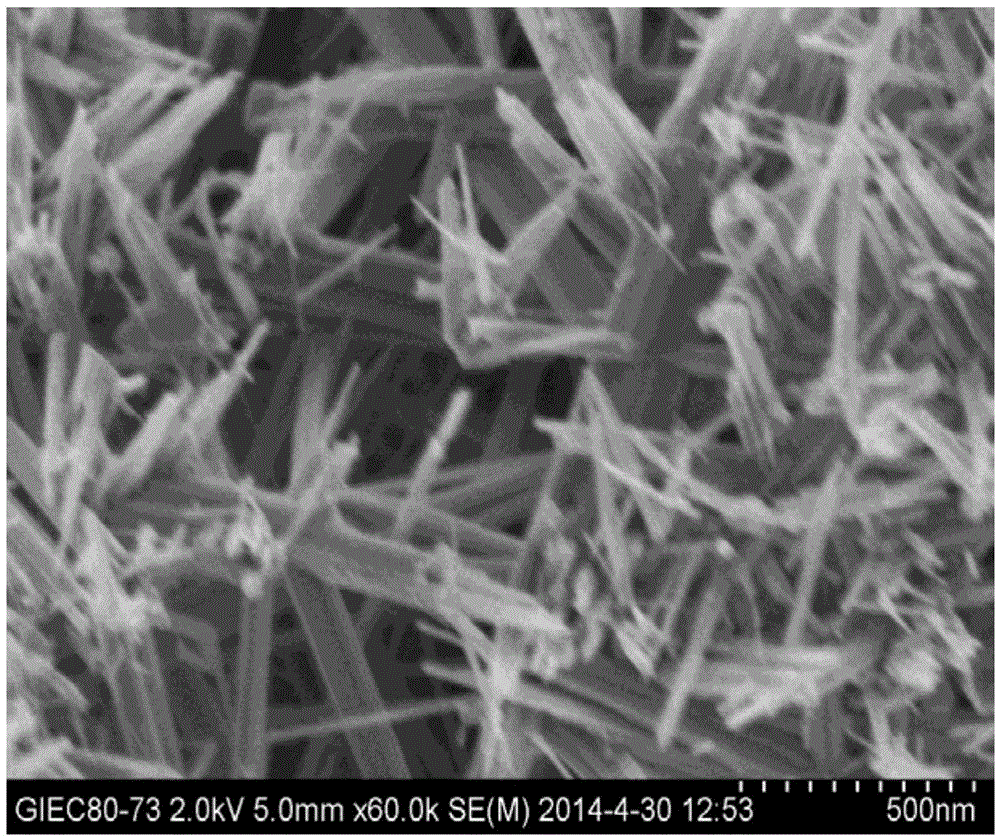

[0026] Add potassium permanganate to deionized water, stir to form a uniform solution with a concentration of 0.3mol / L of potassium permanganate, then add manganese sulfate and stir to form a uniform mixed solution, the mass ratio of potassium permanganate and manganese sulfate 5:2, then transfer the above mixed solution to a high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, react at a temperature of 140°C for 12 hours, then cool to room temperature, filter, and use deionized Rinse with water until neutral, and dry in air at 100° C. to obtain manganese dioxide having a mixed morphology of nanotubes and nanorods (nanorods account for 60%, and nanotubes account for 40%). Subsequently, 0.15g of the above-mentioned manganese dioxide nanomaterials were placed in 60ml0.01mol / LH 2 SO 4 In the solution, ultrasonically suspend, quickly add 100μL pyrrole monomer and 40ml0.01mol / LH 2 SO 4 The mixture of the solution was placed in an ice bath and stirred ...

Embodiment 3

[0028] Add potassium permanganate to deionized water, stir to form a uniform solution with a concentration of 0.3mol / L of potassium permanganate, then add manganese sulfate and stir to form a uniform mixed solution, the mass ratio of potassium permanganate and manganese sulfate 5:2, then transfer the above mixed solution to a high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, react at a temperature of 140°C for 18 hours, then cool to room temperature, filter, and use deionized Rinse with water until neutral, and dry in air at 100°C to obtain manganese dioxide nanorods. Subsequently, 0.15g of the above-mentioned manganese dioxide nanoparticles were placed in 60ml0.01mol / LH 2 SO 4 In the solution, ultrasonically suspend, quickly add 100μL pyrrole monomer and 40ml0.01mol / LH 2 SO 4 The mixture of the solution was placed in an ice bath and stirred for 3 hours, then filtered, and the filtered solid deionized water and ethanol were alternately washed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com