A raw coal transparent pouring part, preparation method and permeability test device

A technology of penetration testing and raw coal, which is applied in the direction of measuring devices, preparation of test samples, permeability/surface area analysis, etc., can solve the problems of being vulnerable to damage, samples not up to standard, easy to move, etc., to achieve high transparency, The effect of visual observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

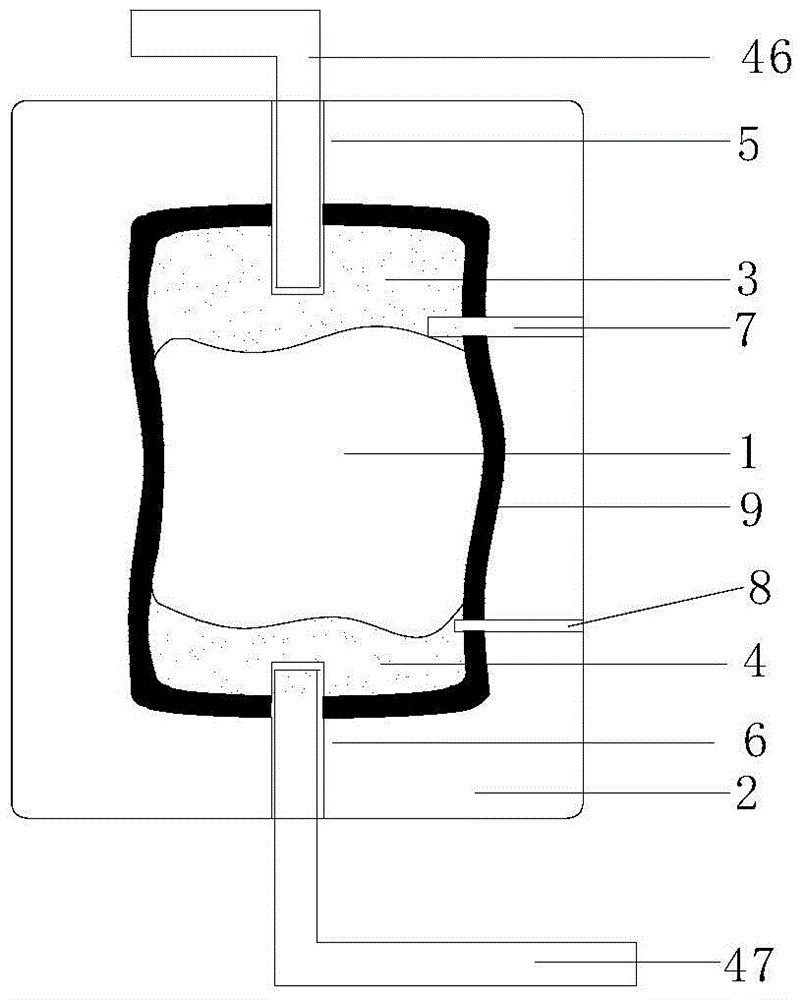

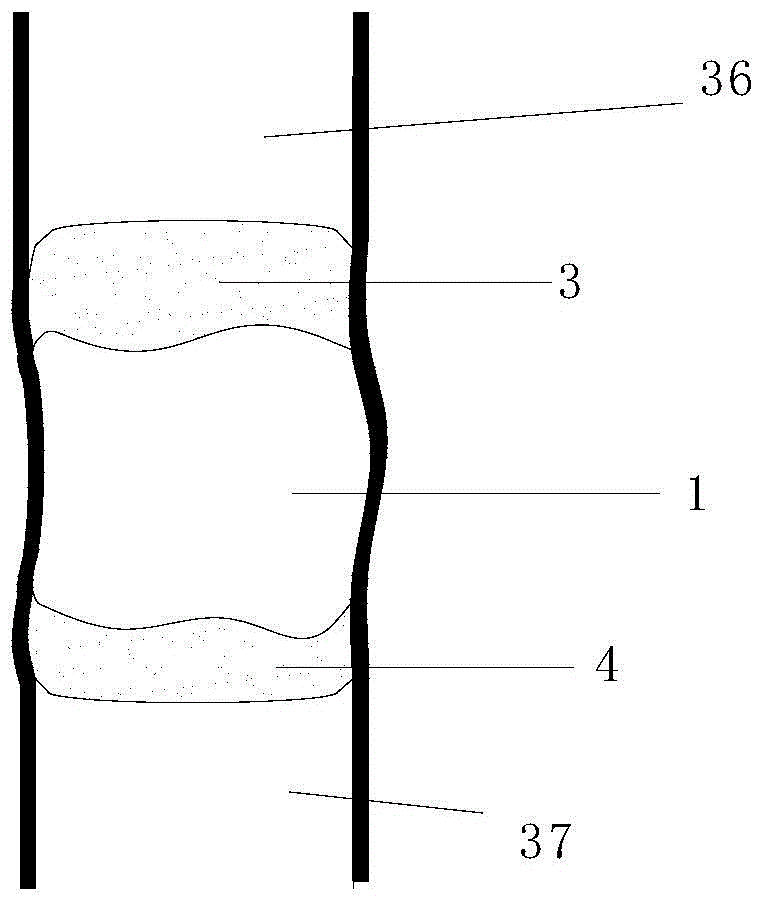

[0040] (1) Preparation of raw coal transparent cast parts

[0041] (1) Fabrication of transparent material inclusions comprising raw coal 1 and upper and lower soluble salt layers 3 and 4. The raw coal sample is taken out from the coal mining face, and it is ground into raw coal 1. The raw coal 1 has an irregular block structure, and the length of each side of the raw coal 1 is about 20 cm. Seal the raw coal 1 with a plastic film, put it into a measuring cup, measure the volume of the raw coal 1, take it out from the measuring cup after the volume measurement is completed, pull off the plastic film on its surface, roll up the raw coal 1 with a transparent material 9, The width of the transparent material 9 is about 40 cm larger than the height of the raw coal 1, and upper and lower cylindrical spaces 36, 37 about 15 cm high are formed on the upper and lower surfaces of the raw coal 1. The soluble salt is poured in, and the thickness of the upper and lower soluble salt layers ...

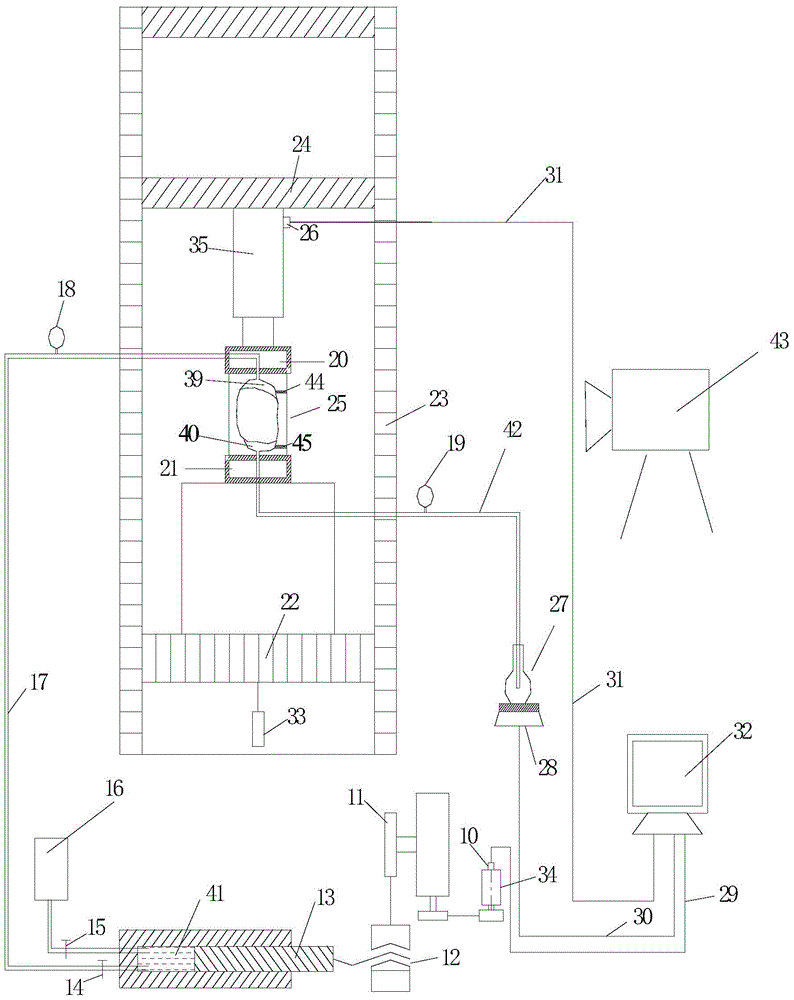

Embodiment 1

[0057] A raw coal transparent pouring part, a preparation method and a permeability testing device, the specific implementation steps are as follows:

[0058] (1) Preparation of raw coal transparent castings. Take out the raw coal from the coal mining face, grind the others into irregular raw coal 1, and measure the length of each side of the raw coal 1 with a vernier caliper between 15 and 21 cm. The raw coal 1 is sealed and wrapped with a plastic film, and put into a measuring cup. The measured volume of the raw coal 1 is 0.00759m 3 After the volume measurement of the raw coal 1 is completed, take it out from the measuring cup, pull off the plastic film on its surface, roll up the raw coal 1 with a transparent material 9 with a width of 80 cm, and form an upper columnar shape on the upper and lower surfaces of the raw coal 1 Space 36 and lower columnar space 37, the height of described upper and lower columnar spaces is about 15cm. Pour sodium chloride particles into the u...

Embodiment 2

[0067] This embodiment adopts the same implementation method as that of Example 1, the difference is that: step (1) the length of each side of the raw coal 1 is between 18 and 22 cm, and the measured volume of the raw coal 1 is 0.00869m 3 , using 0.1kg of curing agent (methyl ethyl ketone peroxide), 0.1kg of LCC colorless accelerator was added to 12kg of unsaturated phenolic resin at one time, and evenly stirred to prepare a resin slurry, the body of the raw coal transparent casting is lavender, and the transparency is not as good Example 1, but raw coal 1 can still be observed from the outside.

[0068] The above processing conditions obtained: the high-speed camera 43 can clearly photograph the seepage path 38 of the aqueous solution with milky white dye in the cracks of the raw coal, but the image clarity is not as good as that of Example 1, and basically the visual observation of the seepage law of the cracks of the raw coal can be realized. The permeability coefficient k=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com