A tunnel kiln structure and a method for treating organically polluted soil in the tunnel kiln

A tunnel kiln and tunnel technology, applied in the field of organic polluted soil treatment, can solve the problems of increased heating time, long repair time, complicated implementation, etc., and achieve the effects of accelerating the temperature rise rate, increasing the contact surface area, and increasing the effect of smoke exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

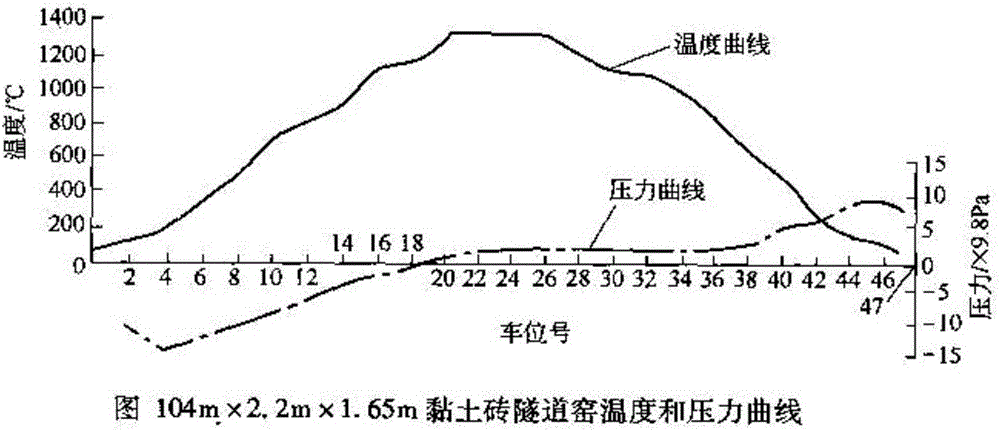

[0055] Example: A pesticide factory produced pesticides from 1959 to 2003. In March 2006, a real estate company took pictures of the plot; from April to May 2007, the engineering survey found that there was a smell of pesticides; in June 2007, the tower crane foundation Poisoning incidents of construction and foundation pit workers; in July 2007, a company assessed soil pollution; in August 2007, experts consulted on the assessment report; from August to October 2007, a detailed investigation was conducted again to determine the degree and scope of soil pollution ; In April 2008, the EIA company submitted the "Suggestion on Soil Pollution Remediation"; on May 6, 2008, it approved the proposal and redesigned the treatment plan; from June 3 to 23, 2008, China University of Geosciences designed the restoration plan. From July 2008 to November 2008, expert demonstration of the scheme. In February 2009, it was orally entrusted by Wuhan Environmental Protection Bureau to carry out i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com