A kind of bimetal composite pipe and its manufacturing process

A bimetallic composite pipe and process technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor surfacing welding quality and difficult surfacing welding, etc., so as to improve the bonding performance, increase the welding area, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

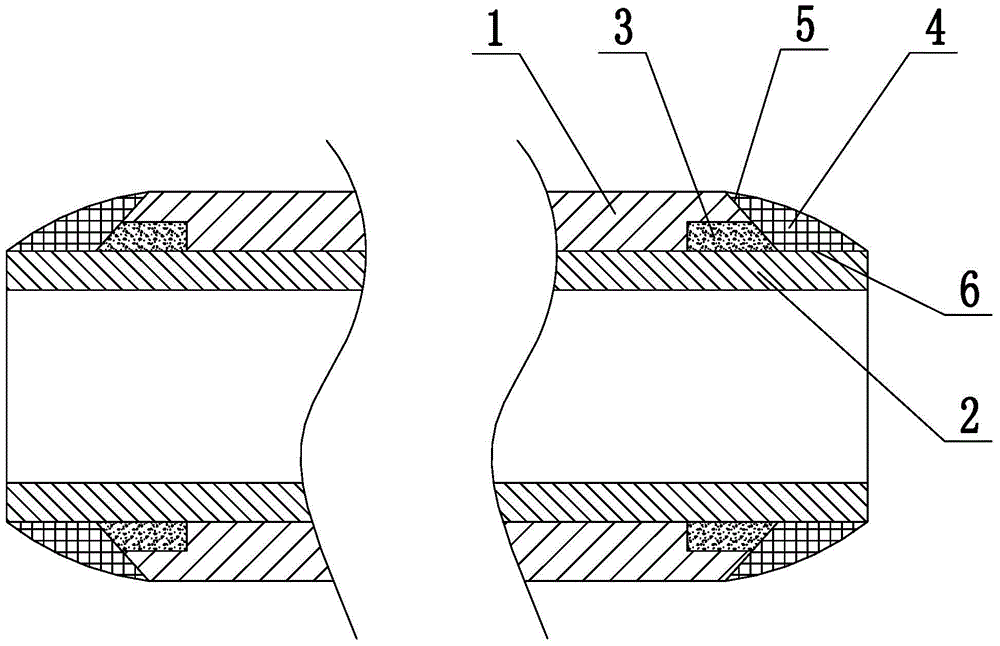

[0028] like figure 1 A bimetallic composite pipe shown includes a base pipe 1 and a liner pipe 2 sleeved inside the base pipe 1, and both ends of the base pipe 1 are provided with 30° grooves 5, and the base pipe 1 Annular grooves are provided on the inner walls of both ends of the base pipe 1 along the circumferential direction, and a surfacing layer 3 is arranged in the annular groove, and the inner liner 2 exceeds the surfacing layer 3 to form a blunt edge 6. The blunt edge 6 is provided with a sealing welding layer 4 for welding the base pipe 1 , the surfacing layer 3 and the lining pipe 2 together along the circumferential direction of the lining pipe 2 .

[0029] In this embodiment, the outer end surface of the welding overlay layer 3 and the end surface of the groove 5 are located on the same plane, and the maximum thickness of the overlay welding layer 3 along the vertical direction of the bimetal composite pipe is 2 mm.

[0030] In this embodiment, the length of the ...

Embodiment 2

[0042] This embodiment is the same as Embodiment 1, except that the angle of the groove 5 is 20°, the maximum thickness of the surfacing layer 3 along the vertical direction of the bimetallic composite pipe is 2.5mm, and the inner wall of the surfacing layer 3 is along the double The axial length of the metal composite pipe is 30 mm, the axial length of the blunt side 6 along the bimetal composite pipe is 5 mm, the wall thickness of the base pipe 1 is 4 mm, and the thickness of the inner liner pipe 2 is 3 mm.

Embodiment 3

[0044] This embodiment is the same as Embodiment 1, except that the angle of the groove 5 is 50°, the maximum thickness of the surfacing layer 3 along the vertical direction of the bimetallic composite pipe is 1.5mm, and the inner wall of the surfacing layer 3 is along the double The axial length of the metal composite pipe is 8 mm, the axial length of the blunt side 6 along the bimetal composite pipe is 2 mm, the wall thickness of the base pipe 1 is 5 mm, and the thickness of the inner liner pipe 2 is 0.5 mm.

[0045] The bimetallic composite pipe of the present invention can ensure the effective compounding of the base pipe and the end of the lining pipe by setting an annular groove on the inner wall of the bevel of the base pipe, and setting a surfacing layer in the annular groove, and effectively avoid sealing after compounding. Carburizing at the top of the groove during welding can reduce the wall thickness of the composite pipe lining to 0.5mm, effectively reducing the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com