Method for catalyzing phosphotungstic acid ionic liquid to prepare biodiesel

An ionic liquid, biodiesel technology, applied in chemical instruments and methods, biofuels, fatty acid esterification, etc., can solve the problems of easy loss of active components, and achieve the effects of low price, mild reaction conditions, and no corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

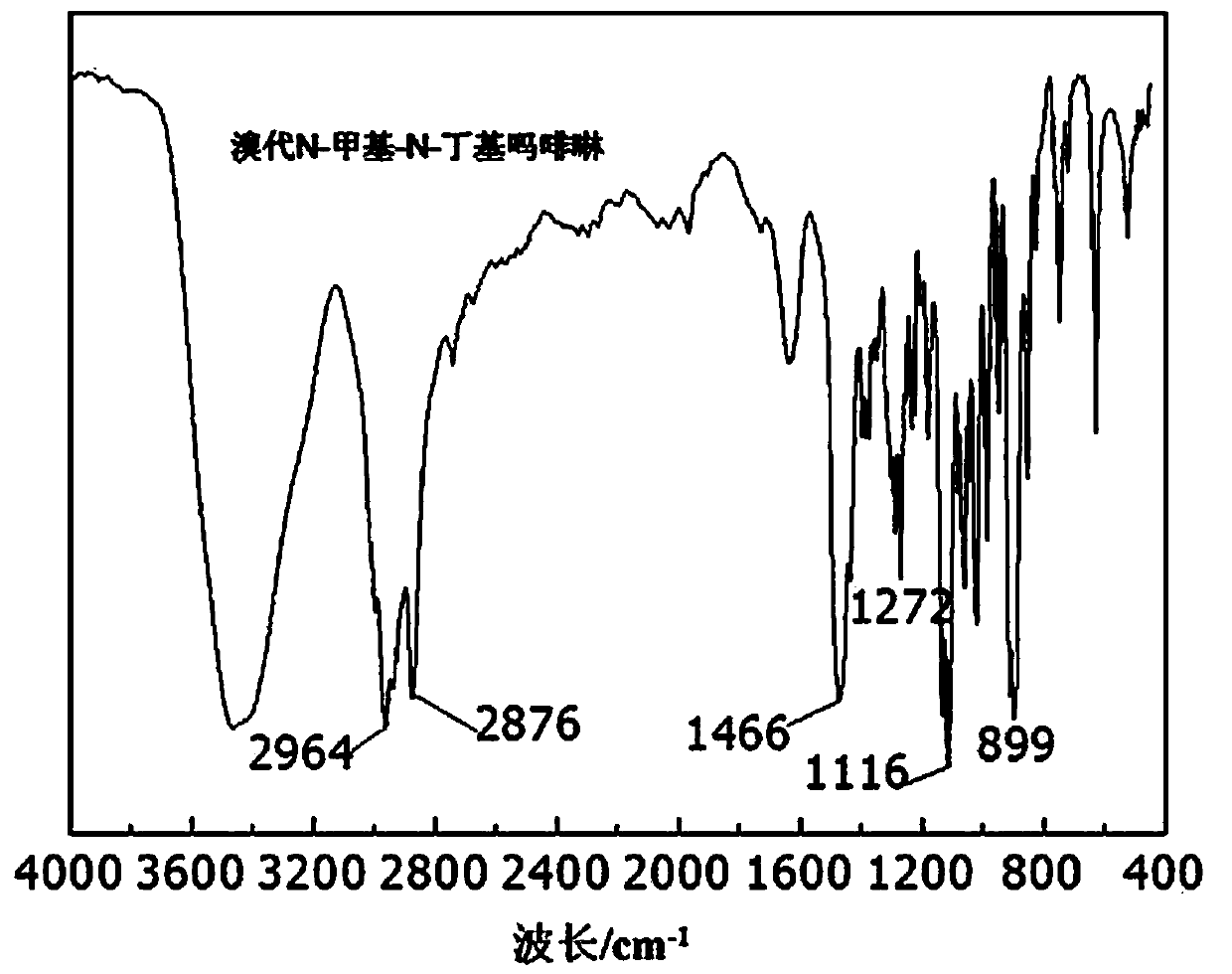

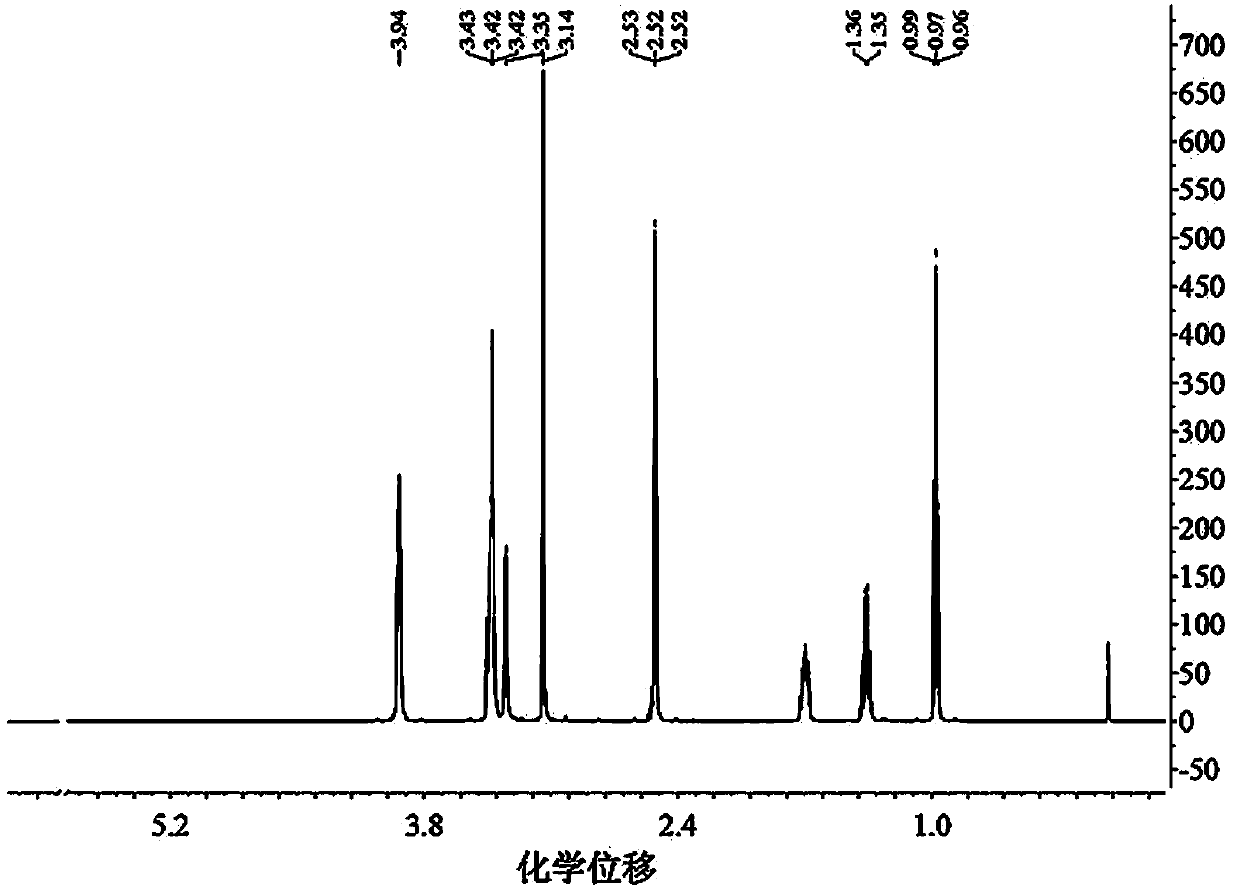

[0037] The intermediate bromo-N-methyl-N-butylmorpholine was added dropwise to aqueous phosphotungstic acid (3:1 molar ratio) using a constant-pressure dropping funnel, and reacted at room temperature for 24 hours. The obtained product was washed three times with deionized water to achieve the purification effect. The product was dried in a vacuum oven (0.02MPa) at 60°C to constant weight, and then activated at 120°C for 3 hours to obtain activated N-methyl-N-butylmorpholine phosphotungstic acid ionic liquid.

[0038] Add soybean oil and methanol into a three-necked flask with a reflux condensation device at a molar ratio of 1:40, and then add phosphotungstic acid ionic liquid whose mass is 5% of the mass of soybean oil. React at a reaction temperature of 60°C and under normal pressure for 8 hours. After the reaction, methanol is distilled off under reduced pressure. The remaining mixture is centrifuged to remove the solid catalyst. The rest of the liquid is transferred to a s...

Embodiment 2

[0040] The intermediate N-methyl-N-dodecylmorpholine bromide was added dropwise to aqueous phosphotungstic acid (3:1 molar ratio) using a constant-pressure dropping funnel, and reacted at room temperature for 24 hours. The obtained product was washed three times with deionized water to achieve the purification effect. The product was dried in a vacuum oven (0.02MPa) at 60°C to constant weight, and then activated at 120°C for 3 hours to obtain activated N-methyl-N-dodecylmorpholine phosphotungstic acid ionic liquid.

[0041] Add castor oil and methanol into a three-necked flask with a reflux condensation device at a molar ratio of 1:40, and then add phosphotungstic acid ionic liquid whose mass is 5% of the mass of castor oil. React at a reaction temperature of 45°C and under normal pressure for 8 hours. After the reaction, methanol is distilled off under reduced pressure. The remaining mixture is centrifuged to remove the solid catalyst. The upper layer is mainly biodiesel. Th...

Embodiment 3

[0043]The intermediate bromo-N-methyl-N-butylmorpholine was added dropwise to aqueous phosphotungstic acid (3:1 molar ratio) using a constant pressure dropping funnel, and reacted at room temperature for 48 hours. The obtained product was washed three times with deionized water to achieve the purification effect. The product was dried in a vacuum oven (0.02MPa) at 60°C to constant weight, and then activated at 150°C for 3 hours to obtain activated N-methyl-N-butylmorpholine phosphotungstic acid ionic liquid.

[0044] Add rapeseed oil and methanol into a three-necked flask with a reflux condensation device at a molar ratio of 1:20, and then add phosphotungstic acid ionic liquid whose mass is 5% of the mass of rapeseed oil. React at a reaction temperature of 64°C and under normal pressure for 8 hours. After the reaction, the methanol was distilled off under reduced pressure, and the remaining mixture was centrifuged to remove the solid catalyst. The upper layer is mainly biodie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com