A zno-mgo-tio2 series ltcc material

A zno-mgo-tio2, zn1-xmgx technology, applied in the field of dielectric ceramics, can solve problems such as instability and high slurry viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

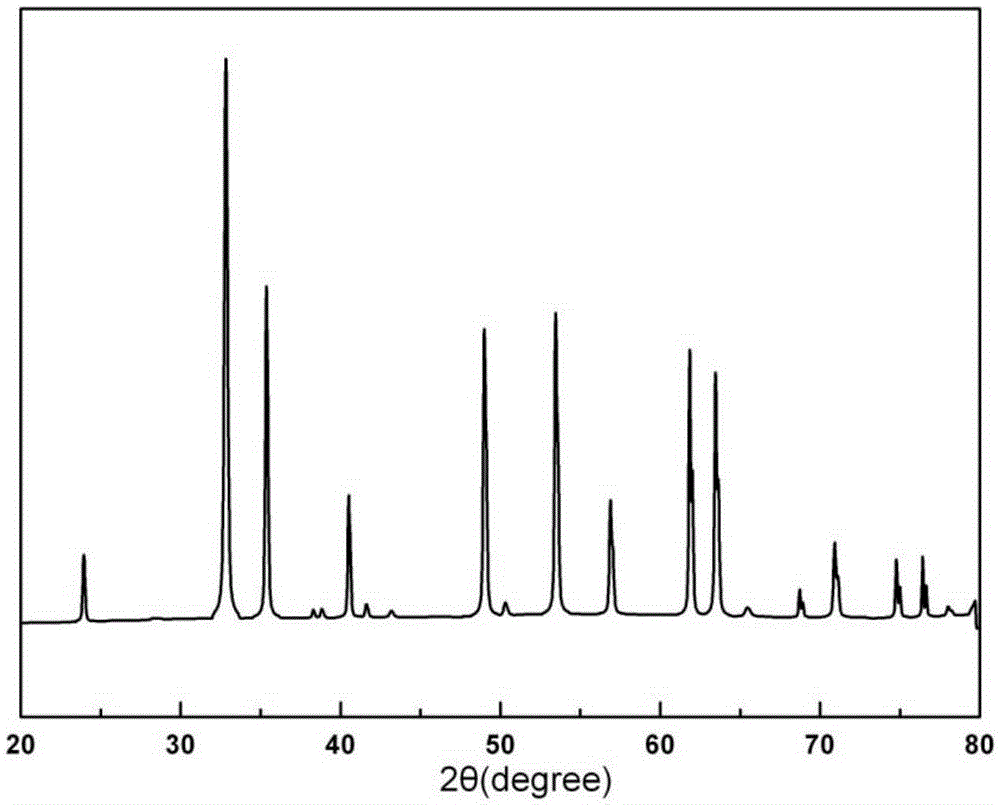

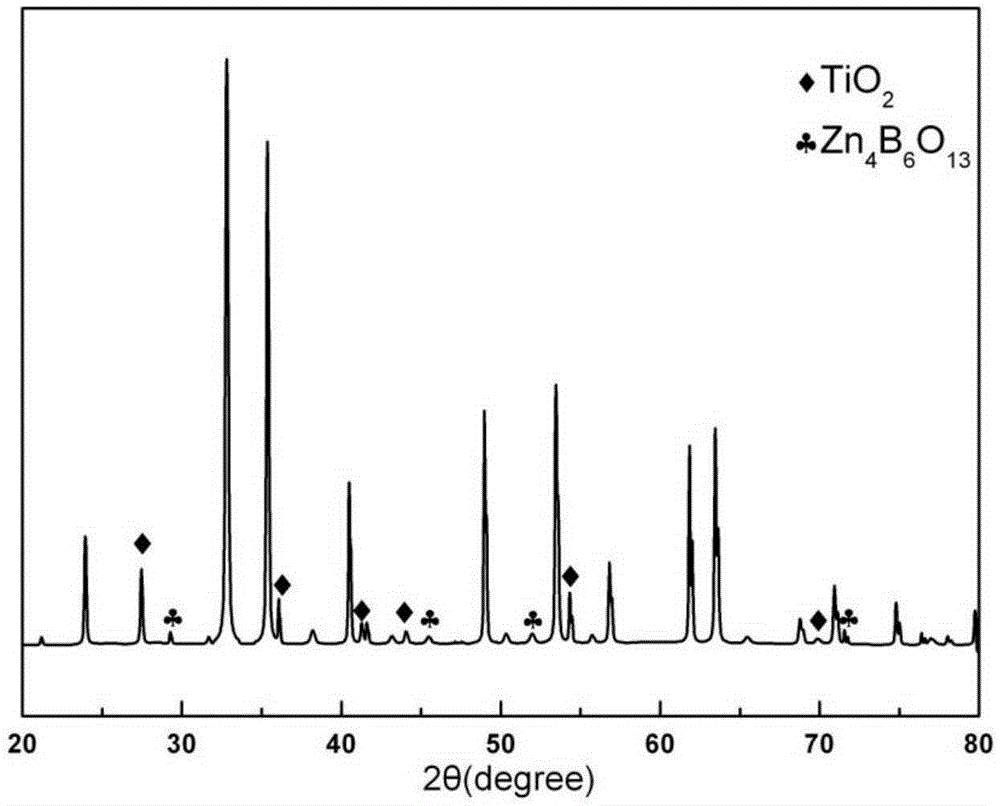

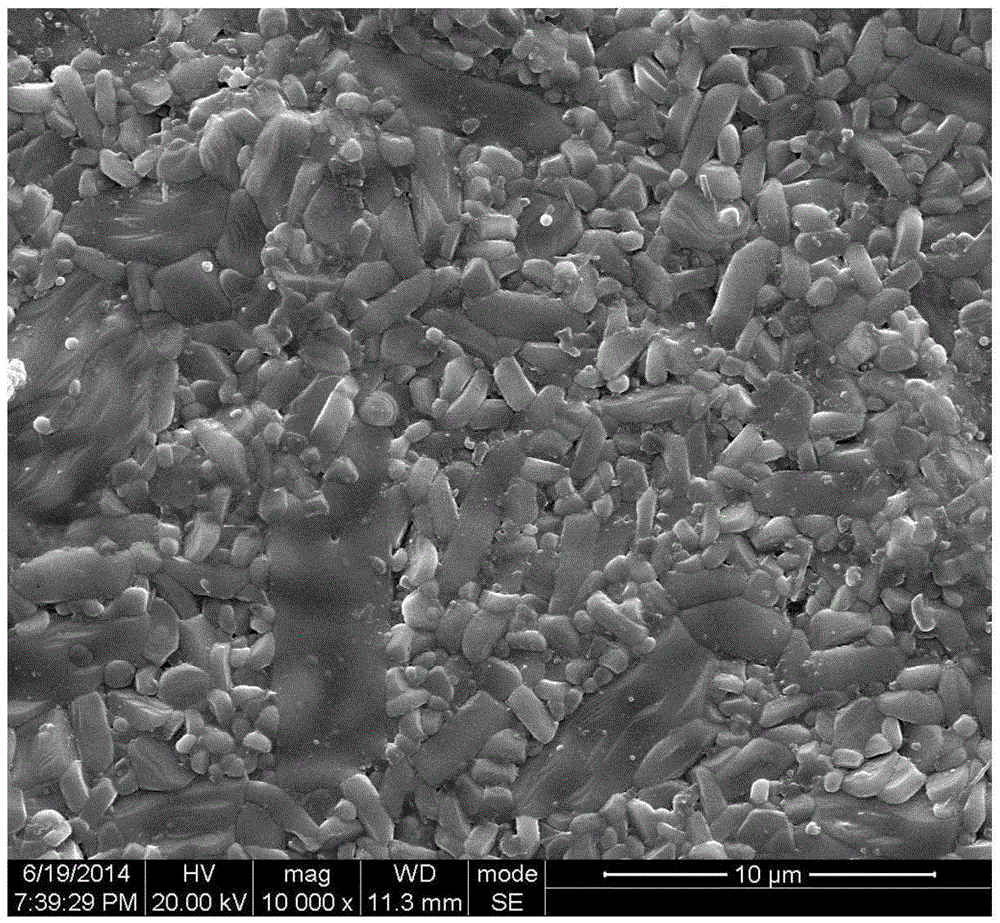

[0024] The material of the present invention is made of ZnO-MgO-TiO 2 The composition of the system material and the zinc borosilicate glass whose weight percentage is z (0.25%≤z≤5%) of the main crystal phase can obtain the material of the present invention through solid state reaction. ZnO-MgO-TiO 2 The composition of the material is (Zn 1-x Mg x )TiO 3 -yTiO 2 , where: 0.05≤x≤0.15, 0≤y≤0.3.

[0025] Material manufacturing method of the present invention is:

[0026] Step 1: Preparation of the main crystal phase, zinc oxide (ZnO), magnesium oxide (MgO), titanium dioxide (TiO 2 ) of the original powder according to (Zn1-x Mg x )TiO 3 -yTiO 2 Composition of ingredients, wherein: 0.05≤x≤0.15, 0≤y≤0.3; the ingredients are mixed with alcohol as ball milling medium, wet ball milling for 8-24 hours, and pre-fired in 700℃~900℃ atmosphere for 4~24 hours after drying 12 hours to synthesize the main crystal phase (Zn 1-x Mg x )TiO 3 -yTiO 2 ;

[0027] Step 2: Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com