Solution Thermal Preparation of Self-supporting Porous Graphene-Based Thin Films

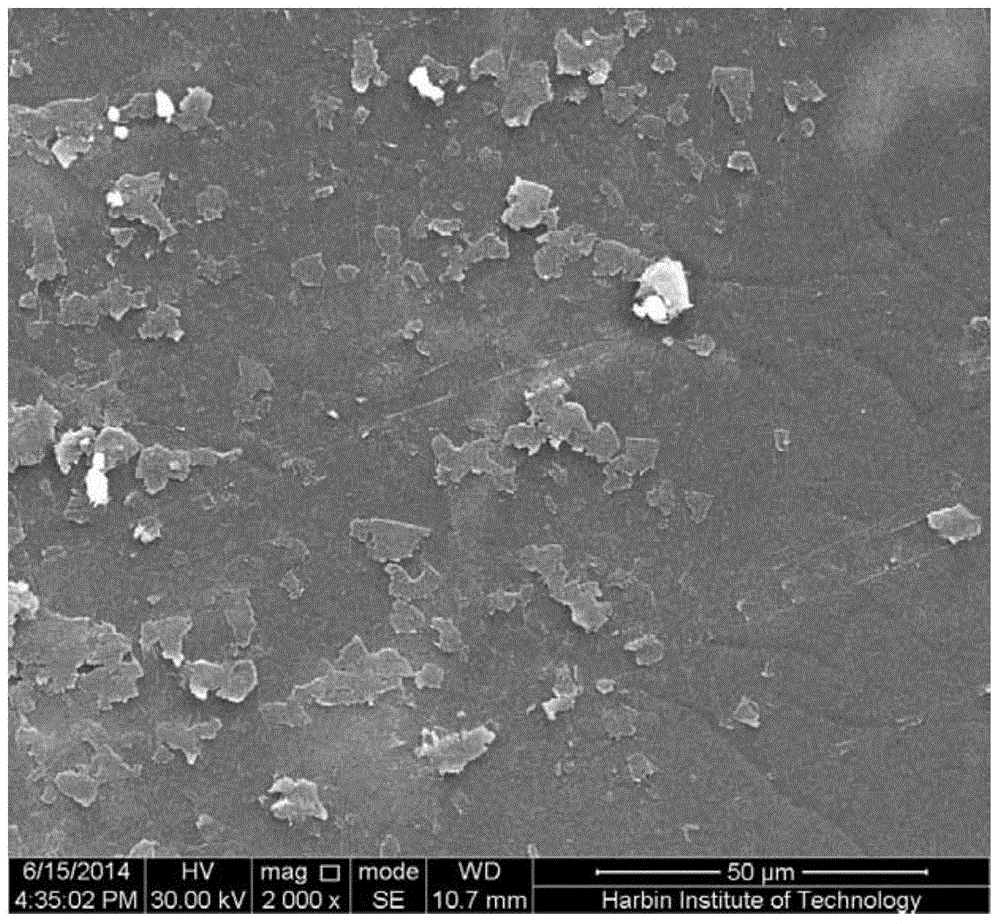

A porous graphene and graphene-based technology, applied in the field of graphene-based thin film preparation, can solve problems such as poor electrochemical performance, limited size and thickness of self-supporting graphene-based thin films, and achieve the effect of increasing the specific capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0061] Embodiment one: the solution thermal preparation method of the self-supporting porous graphene-based film of the present embodiment is carried out according to the following steps:

[0062] 1. The concentration of graphite oxide is 0.01mg·mL -1 ~0.5mg·mL -1 , adding graphite oxide into water, ultrasonically exfoliating and dispersing for 0.5-10 hours under ultrasonic conditions with a frequency of 20-100KHz, to obtain a graphene oxide aqueous dispersion;

[0063] 2. Under the condition that the temperature is 20° C. to 100° C., the graphene oxide aqueous dispersion obtained in step 1 is evaporated under reduced pressure or evaporated at normal pressure to concentrate;

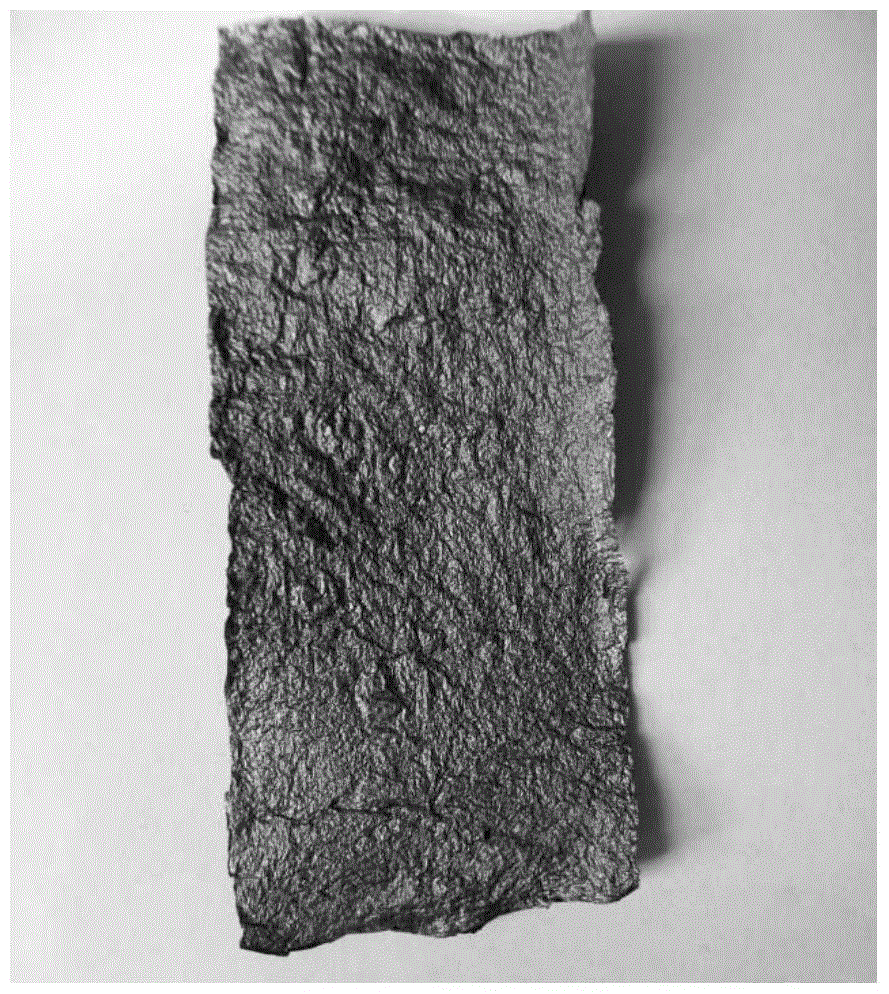

[0064] 3. Spread the graphene oxide aqueous dispersion concentrated in step 2 to form a film on the flat substrate, and after drying at room temperature, peel off the film from the substrate to obtain a graphene oxide film;

[0065] 4. According to the solute concentration of 0.01mol L -1 ~20mol·L -1...

specific Embodiment approach 2

[0067] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the preparation method of graphite oxide described in step one is as follows: in a dry beaker, add 120mL of H with a mass percentage concentration of 98% 2 SO 4 , then place the beaker in an ice-water bath, add 5g graphite and 2.5g NaNO 3 , stirring at a speed of 50-500 rpm, while gradually adding 15g of powdered KMnO 4 , continue to react for 2 hours in an ice-water bath and stirring; move the beaker into a constant temperature oil bath at 35±1°C and continue to react for 2 hours; slowly add 360mL of distilled water under stirring at a speed of 50 to 500 rpm, and control the temperature to be constant At 75°C, continue the constant temperature reaction for 1h; add 1000mL of distilled water at a temperature of 40°C, add 50mL of hydrogen peroxide with a concentration of 30% by mass, and then vacuum filter; wash the filter cake with hydrochloric acid with a concentration o...

specific Embodiment approach 3

[0069] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the decompression evaporation described in step two has a temperature of 40°C to 90°C, a vacuum degree of -0.07MPa to -0.1Mpa, and a rotation speed of 20 RPM~500 RPM rotary evaporation under reduced pressure. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com