Synchronous powder feeding space laser machining and three-dimensional forming method and device

A laser processing and three-dimensional forming technology, applied in additive processing, laser welding equipment, metal processing equipment, etc., can solve problems such as step effect, light powder leakage, molten pool flow, etc., and achieve the effect of simple trajectory and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: A method for synchronous powder feeding space laser processing and three-dimensional forming, including the following steps:

[0039] (1) Divide the expected multi-branch complex 3D entity into one or several forming units according to the principles of body simplification and nozzle cladding scanning accessibility, and select the forming sequence of each unit in turn. Each forming unit has its own ultimate Optimum shape growth direction and regularity.

[0040] (2) Dividing the forming unit obtained in step (1) into several layers along the stacking direction, and each layer includes at least one of the filling area and the boundary area;

[0041] (3) Adopt the method of single-beam air-borne powder delivery in the hollow ring laser light, control the mechanical arm to drive the light-inner powder delivery nozzle to scan and move in the boundary area and filling area of a layer according to the predetermined track, and complete the melting of the layer ...

Embodiment 2

[0047] Embodiment two: see Figure 6 As shown, the 3-branch three-dimensional forming is divided into three simple forming units a, b, and c according to the principle of physical simplification and the accessibility of the internal powder-feeding nozzle. Among them, the forming growth direction of the forming unit a11 is a1, and the forming growth direction of the forming unit b12 is The forming growth direction is b1, the forming growth direction of the forming unit c13 is c1, and the forming sequence is: first complete the forming of the forming unit a11, and then control the mechanical arm 7 to move the internal powder feeding nozzle 1 to the initial position of the forming unit b12, Complete the forming of the forming unit b12 on the side wall of the forming unit a11, then control the mechanical arm 7 to move the internal powder feeding nozzle to the starting position of the forming unit c13, and complete the forming of the forming unit c13 on the other side of the forming...

Embodiment 3

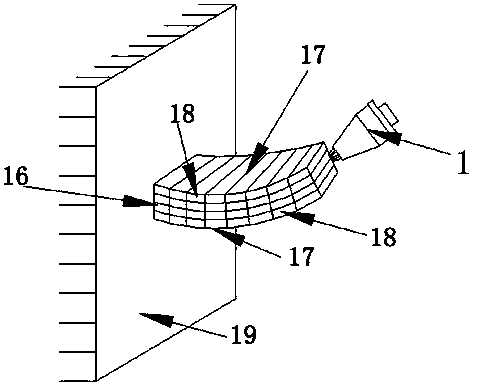

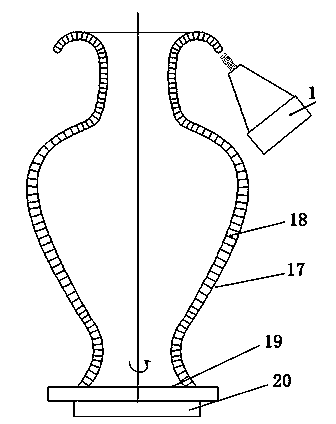

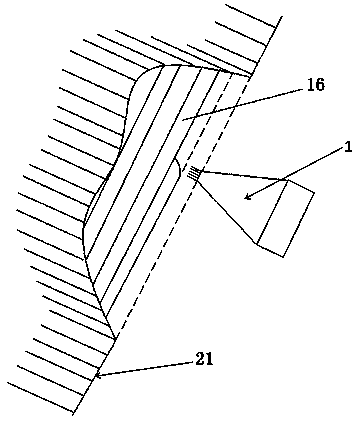

[0048] Embodiment three: see Figure 7 and 8 As shown in the figure, the simultaneous powder-feeding space laser processing and three-dimensional forming of curved and overhanging structural parts adopts the method of sub-area, and divides the forming unit into several layers along the optimal growth and accumulation direction, and each layer is divided into a boundary area 18 and a filling area 16 . The layering principle of the boundary area 18 is: slice and layer along the boundary surface 17 which is always perpendicular to the boundary surface normal direction. When the boundary surface is straight, the layers are parallel to each other. When the boundary surface is a curved surface, each layer is mutually parallel. It may be non-parallel and unequal thickness; the layering principle of the filling area 16 is: the layers are all parallel to the base surface 19, and the layers are also parallel to each other. After the cladding forming of a layer is completed, the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com