One-phase-failure fault-tolerant torque control method of 60-degree offset six-phase permanent magnet synchronous motor

A permanent magnet synchronous motor, a lack of compatible technology, applied in the direction of motor generator control, electronic commutation motor control, control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

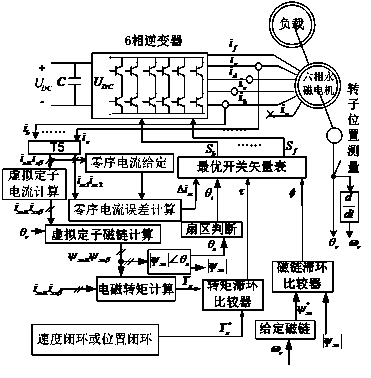

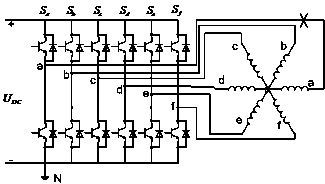

[0058] Please refer to figure 1 and Figure 4 , the present invention provides a six-phase permanent magnet synchronous motor with a bias of 60 degrees and a fault-tolerant torque control method, which is characterized in that it includes the following steps:

[0059] The first step is to collect the remaining healthy phase B~F current and rotor position angle ;

[0060] In the second step, using the T5 orthogonal transformation matrix in formula 1, the remaining healthy five-phase current Transformed into αβ coordinates and zero-sequence shafting :

[0061] (Formula 1)

[0062] ;

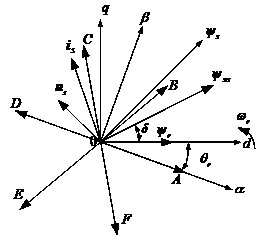

[0063] In the third step, use formula 8 and Calculation of virtual stator current :

[0064] (Formula 8)

[0065] in is the virtual stator flux linkage, is the virtual rotor flux linkage, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com