Wafer testing machine stand

A wafer testing and machine technology, which is applied in semiconductor/solid state device testing/measurement, electrical components, circuits, etc. The effect of reducing time, reducing costs and reducing emergencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical features and advantages of the present invention better understood by those skilled in the art and to implement the present invention, the technical features and implementation methods of the present invention are explained in the following description in conjunction with the accompanying drawings, and Preferred embodiments are listed for further description, but the following descriptions of the embodiments are not intended to limit the present invention, and the accompanying drawings below are schematic representations related to the characteristics of the present invention.

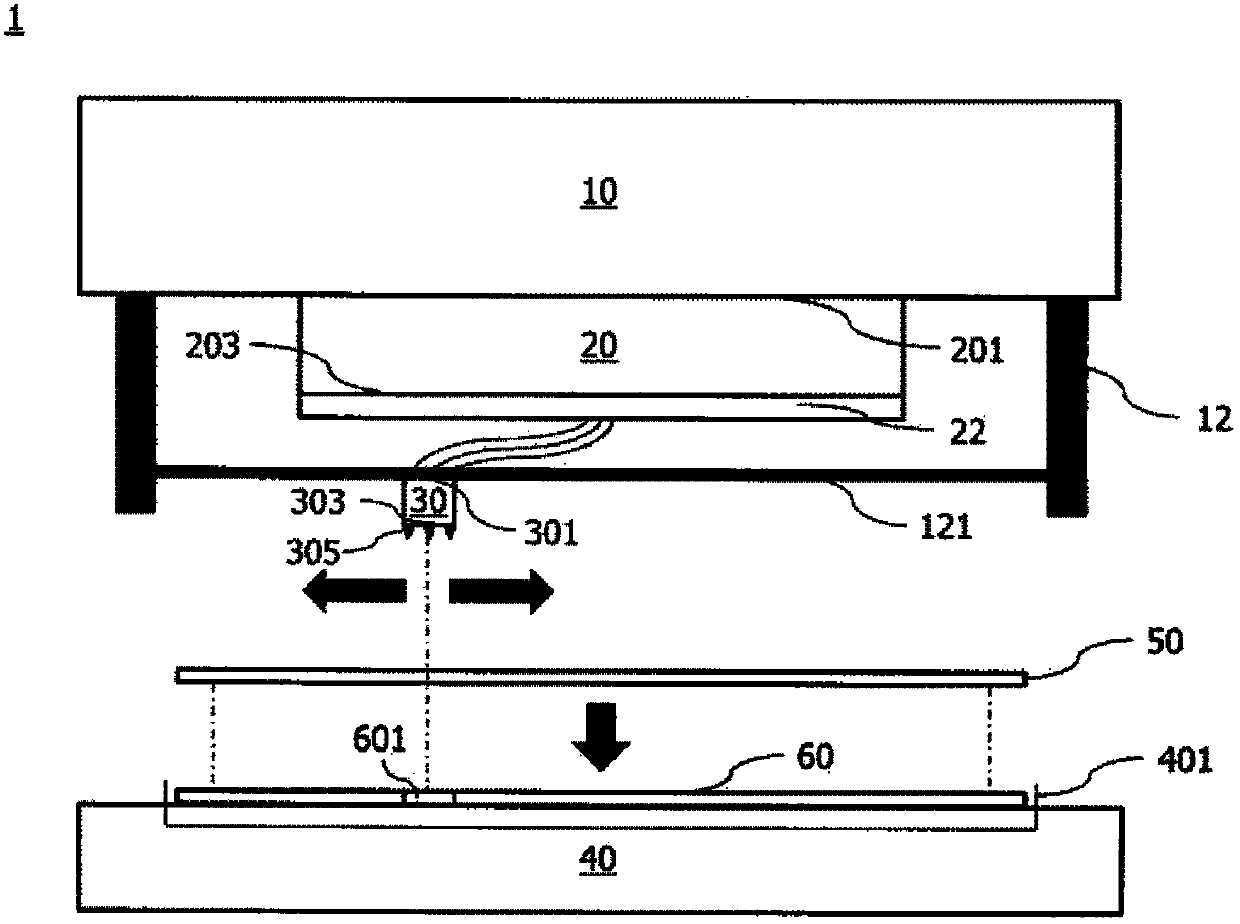

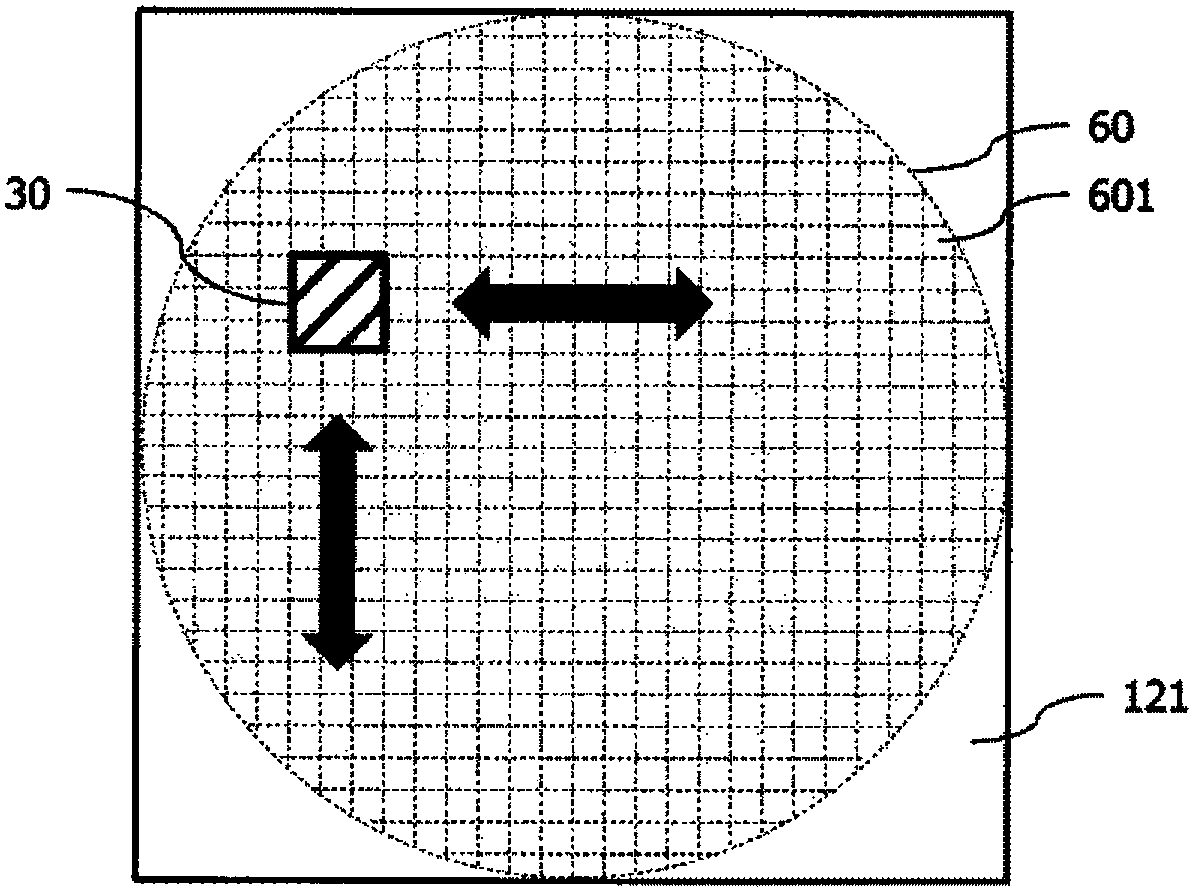

[0015] see figure 1 , is a cross-sectional view of the wafer testing machine of the present invention. Such as figure 1 As shown, the wafer testing machine 1 includes: a test head 10 electrically connected to the outside world; a probe tower 20 having an upper surface 201 and a lower surface 203 opposite to the upper surface 201, wherein the upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com