Method and device for testing mechanical parameters of thin-walled pipe fitting

A technology of mechanical parameters and testing methods, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems of inability to accurately measure the mechanical parameters of thin-walled pipes, and achieve sufficient and stable data collection, test system and test process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] This example is a test Test methods for mechanical parameters of 201 stainless steel pipes (thin-walled pipe fittings).

[0045] The invention uses a high-pressure pump to slowly fill the thin-walled pipe with strain gauges on the outer wall with high-pressure liquid, and uses a strain gauge to record the axial and circumferential strains of the outer wall of the thin-walled pipe during loading and unloading, and uses the least square method to test The data is linearly fitted, and based on the mechanical principle of the measurement of the mechanical parameters of the thin-walled pipe and the internal pressure-strain curve obtained by fitting, the yield strength, elastic modulus, Poisson's ratio, and resistance to internal pressure yield / burst of the thin-walled pipe are calculated. strength.

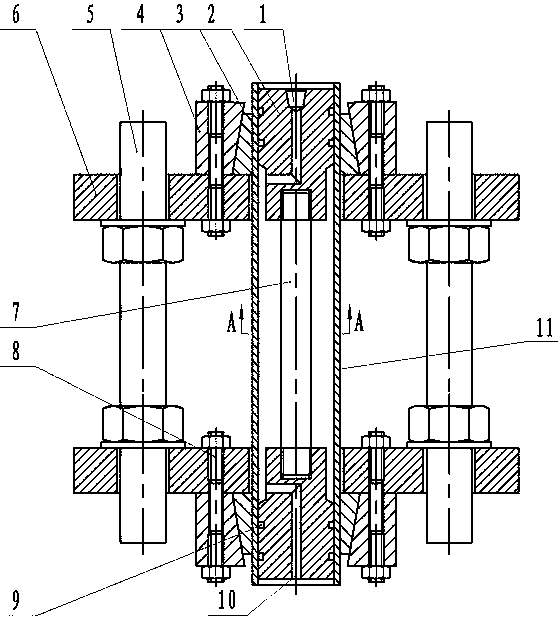

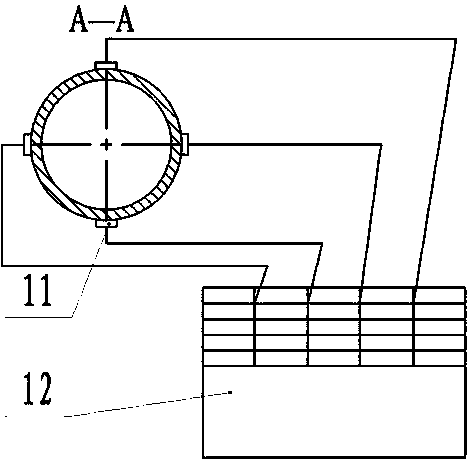

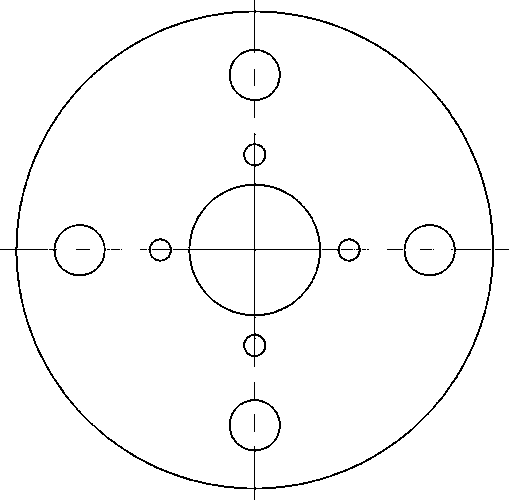

[0046] In order to use the above method, the present invention provides a mechanical parameter testing device for thin-walled pipe fittings, which mainly includes: threaded rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com