Temperature and stress measuring device based on orthogonal dual-polarization fiber laser

A technology of fiber laser and fiber laser, which is applied to measuring devices, thermometers with physical/chemical changes, thermometers, etc., can solve the problems of reducing demodulation accuracy, increasing cost and complexity, and achieving mature, simple and stable manufacturing processes Good, high-sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

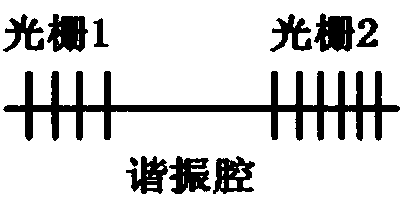

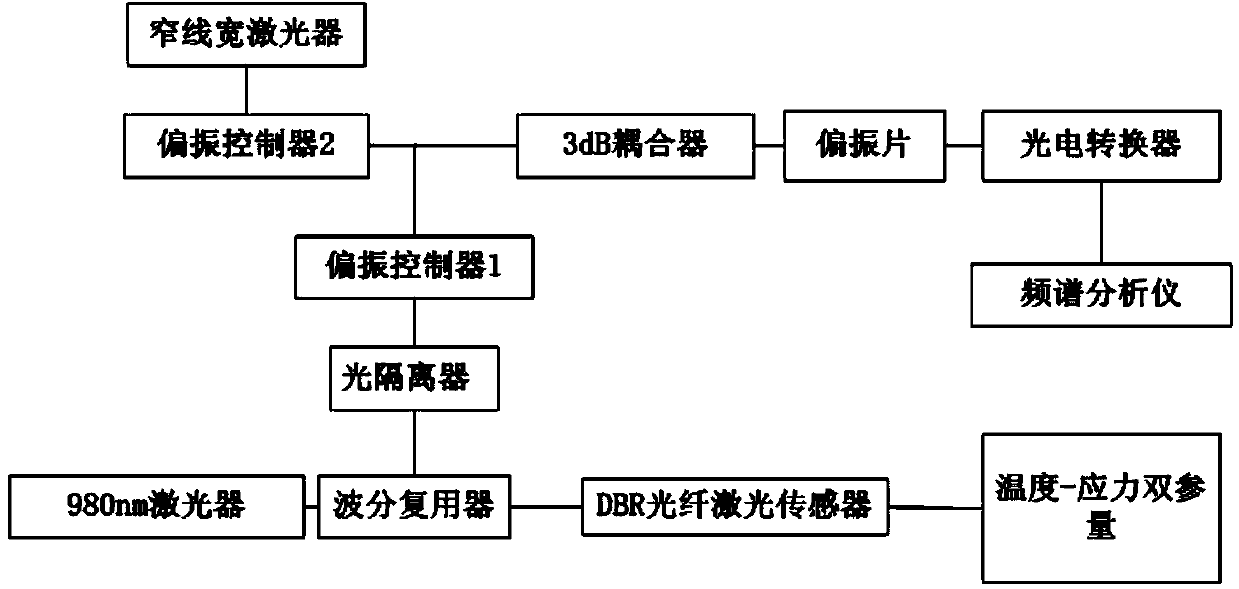

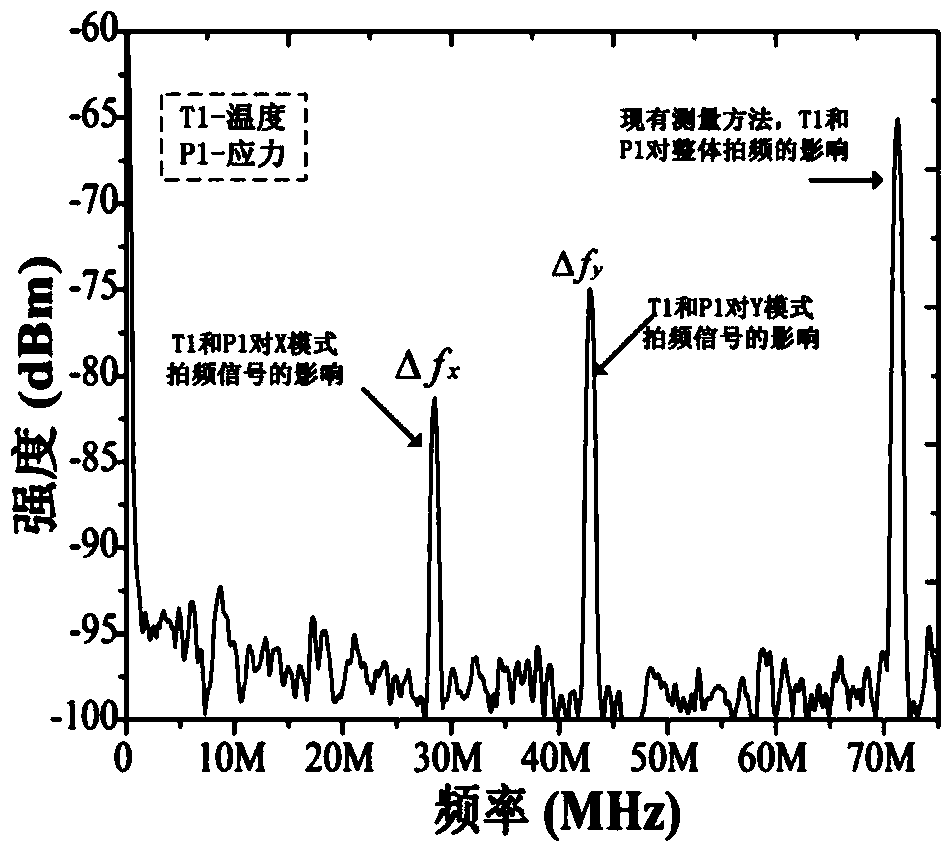

[0013] The invention includes three parts: an optical fiber sensing unit, a signal processing unit and a signal demodulation unit. The optical fiber sensing unit is a single longitudinal mode dual polarization DBR fiber laser sensor; the signal processing unit includes a 980nm laser, a 980 / 1550 nm wavelength division multiplexer, an optical isolator, a polarization controller, a narrow linewidth laser, and 3dB A coupler, a polarizer and a photoelectric converter; the signal demodulation unit is a spectrum analyzer. The sensing unit is a DBR (Distributed Bragg Reflection) fiber laser, which is composed of a pair of FBG gratings and a resonant cavity. See figure 1 . Since the pair of FBG sub-gratings have the same temperature sensitivity and different stress sensitivity, the two groups of gratings have the same temperature sensitivity under the action of external tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com