Antibiotic active substance of Aspergillus flavus biocontrol bacterium, and its separating and purifying method

An antibacterial active substance, separation and purification technology, applied in the field of microbiology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

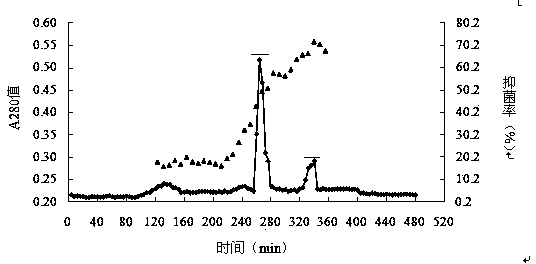

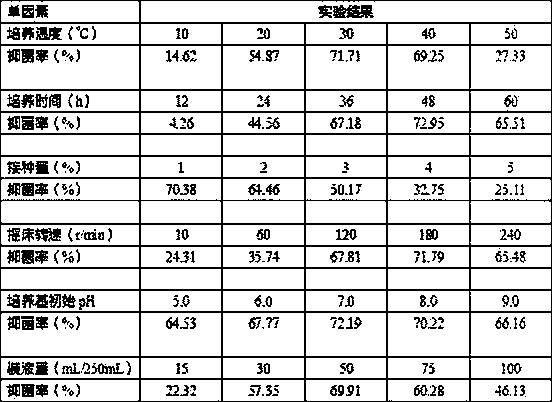

[0024] Embodiment 1: the culture condition screening of Bacillus atrophaeus antibacterial active substance

[0025] Experimental materials: Bacillus atrophaeus is used as the bacterial species; any commercially available medium can be used as the nutrient agar medium, and the composition of this medium used in the present invention is: peptone 10g, beef extract 3g, sodium chloride 5g , agar 17g, distilled water 1000 mL, pH7.2, sterilized at 121°C for 20min.

[0026] The source of Aspergillus flavus used in the test: Inoculate the Aspergillus flavus species on the potato dextrose agar slant medium (PDA), culture at a constant temperature of 30°C for 48 hours, add sterile water (containing 0.1% Tween-80 and 0.1% agar) to it, The vortex mixer oscillated to distribute the spores evenly, and adjusted the concentration of the spore suspension to 1×105 CFU / mL, which was the Aspergillus flavus spore suspension.

[0027] In order to study the influence of different culture conditions ...

Embodiment 2

[0053] Embodiment 2: the determination of crude extraction conditions

[0054] Using the optimal fermentation conditions for the antibacterial active substances screened in the above experiments, Bacillus atrophaeus was shaken and cultured in the nutrient broth medium, and the fermentation liquid was centrifuged at 4°C and 8000r / min for 20min, and the supernatant was collected and passed through 0.45μm The rough extraction experiment of antibacterial active substances was carried out after the microfilter removed the bacteria.

[0055] Ammonium sulfate fractional precipitation: remove 100 mL of bacterial fermentation supernatant, slowly add ammonium sulfate solid powder 10.6g, 22.6g, 36.1g, 51.6g, 69.7g, so that the saturation of ammonium sulfate is 20%, 40% %, 60%, 80%, 100%, and then stand overnight at 4°C, centrifuge at 8000r / min for 20min at 4°C, and collect the precipitate. Dissolve the precipitate in 2 times the volume of pH7.5 0.05mol / L phosphate buffer, transfer it in...

Embodiment 3

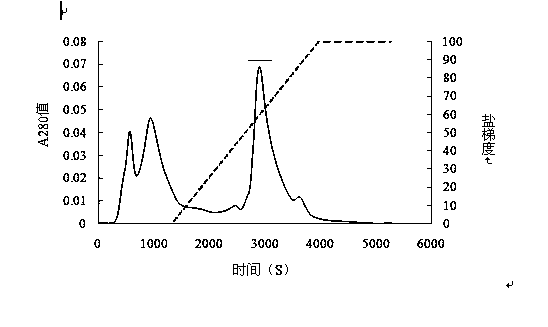

[0060] Embodiment 3: Separation and purification of crude extract

[0061] On the basis of obtaining the crude extract, the present invention further separates and purifies the crude extract. In order to improve the efficiency, the crude extract is first concentrated, and the dialysis bag is cut into small sections of 10-20 cm. / v) Boil in NaHCO3 and 0.01mol / L pH8.0 EDTA for 10min, rinse with distilled water, then boil in 0.01mol / L pH8.0 EDTA for 10min, rinse thoroughly with distilled water after cooling. Tighten the dialysis bag at 1 cm from one end with a thread, pour the crude protein extract to be concentrated into the dialysis bag, reserve 1 / 3 to 1 / 2 of the space, tie the other end tightly with a thread, and put it into a beaker , Sprinkle PEG20000 on the dialysis bag, let it stand at 4°C until the protein in the dialysis bag reaches a certain concentration, then carry out Sephadex G-25 desalting and DEAE Sepharose Fast Flow ion exchange chromatography purification.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com