A separation method of main aroma components in tree moss extract and its application in cigarette flavoring

A technology of moss extract and aroma components, which is applied in the fields of application, essential oils/spices, tobacco, etc., can solve problems such as quality fluctuations of tree moss extract, improve quality stability and safety, improve aroma purity and Quality, the effect of solving quality fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Mix n-hexane, ethyl acetate, ethanol, and water according to the volume ratio of 0.9:0.9:1:1, shake vigorously for 15 minutes, and after standing for 2 hours, the mixed solution is divided into two layers. The upper layer after layering is used as a stationary phase, and the lower layer is used as a Mobile phase: Weigh 1g of the tree moss extract sample, add 20ml of mobile phase, stir and ultrasonically disperse for 10min to obtain the sample solution to be separated.

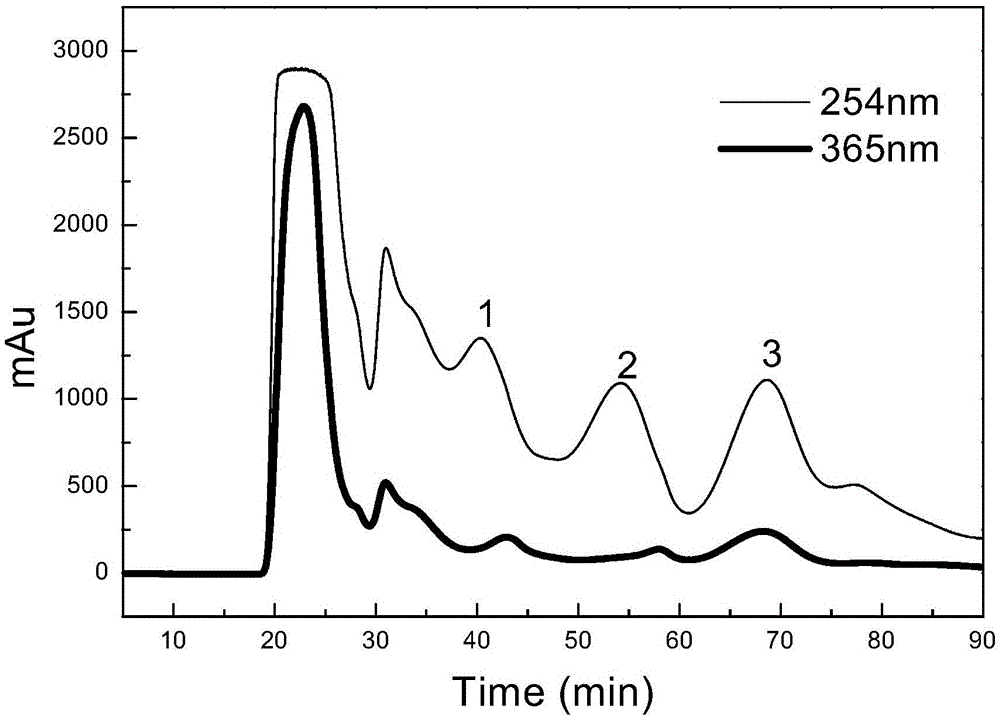

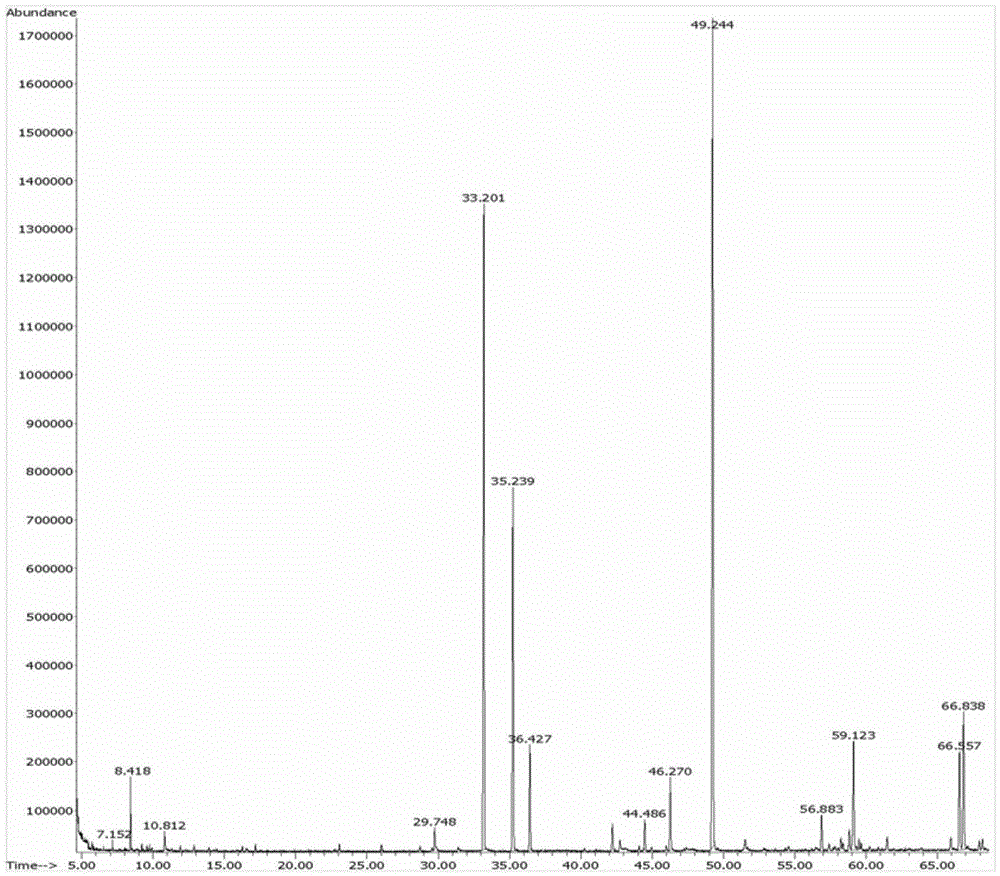

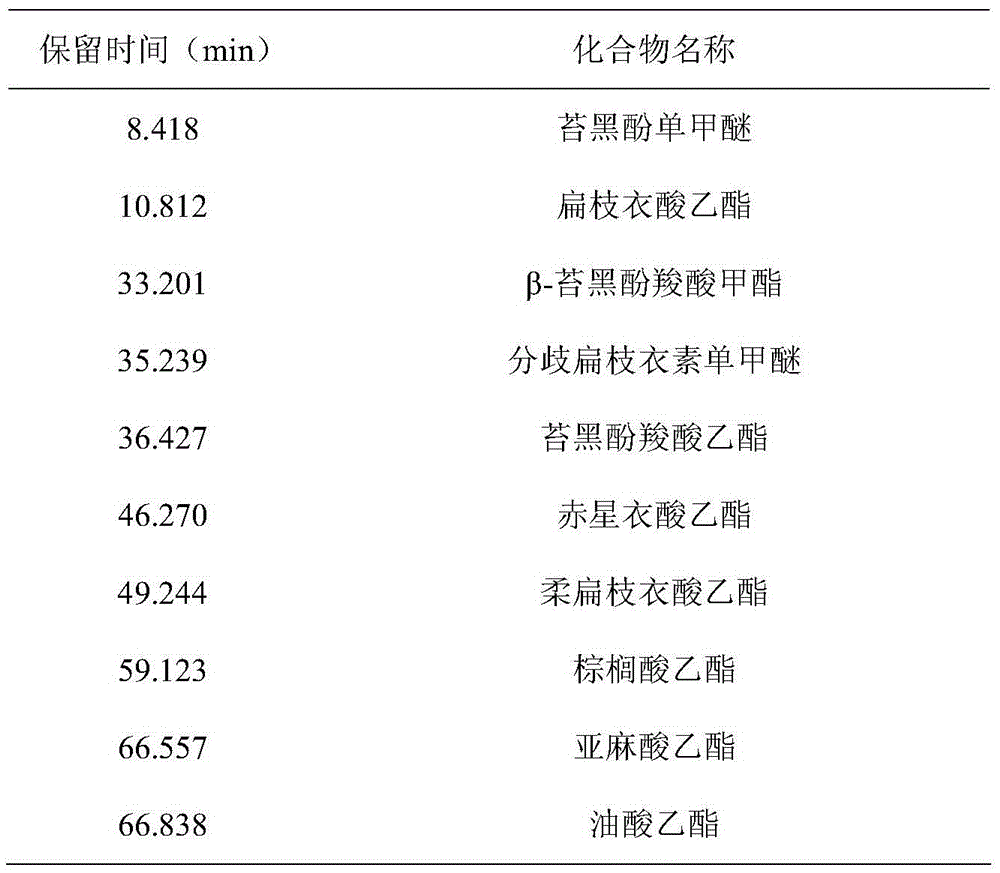

[0037]A TBE-300 semi-preparative high-speed countercurrent chromatograph (Shanghai Tongtian Biochemical Technology Co., Ltd.) was used. The instrument was equipped with a pump, a 10-30ml sampling valve, an ultraviolet detector and a recorder. Its multilayer winding polytetrafluoroethylene tube The column capacity is about 300ml. First fill the separation column of high-speed countercurrent chromatography with stationary phase at a flow rate of 10mL / min, then turn on the speed controller to make the high-...

Embodiment 2

[0042] Mix n-hexane, ethyl acetate, ethanol, and water according to the volume ratio of 0.7:0.7:0.8:1.1, shake vigorously for 25 minutes, and let stand for 1 hour. The mixed solution is divided into two layers. Phase; Weigh 1g of tree moss extract sample, add 30ml of mobile phase, stir and ultrasonically 3min for dispersion, to obtain the sample solution to be separated.

[0043] A TBE-300 semi-preparative high-speed countercurrent chromatograph (Shanghai Tongtian Biochemical Technology Co., Ltd.) was used. The instrument was equipped with a pump, a 10-30ml sampling valve, an ultraviolet detector and a recorder. Its multilayer winding polytetrafluoroethylene tube The column capacity is about 300ml. First fill the separation column of high-speed countercurrent chromatography with a stationary phase at a flow rate of 30mL / min, then turn on the speed controller to make the high-speed countercurrent Phase; after the mobile phase flows out from the outlet, the two-phase solvent sy...

Embodiment 3

[0046] Mix n-hexane, ethyl acetate, ethanol, and water according to the volume ratio of 1.1:1.1:0.8:1.1, shake vigorously for 10 minutes, and let stand for 4 hours. The mixed solution is divided into two layers. phase; Weigh 1g of tree moss extract sample, add 25ml of mobile phase, stir and ultrasonically 15min for dispersion, to obtain the sample solution to be separated.

[0047] A TBE-300 semi-preparative high-speed countercurrent chromatograph (Shanghai Tongtian Biochemical Technology Co., Ltd.) was used. The instrument was equipped with a pump, a 10-30ml sampling valve, an ultraviolet detector and a recorder. Its multilayer winding polytetrafluoroethylene tube The column capacity is about 300ml. First fill the separation column of high-speed countercurrent chromatography with a stationary phase at a flow rate of 20mL / min, then turn on the speed controller to make the high-speed countercurrent Phase; after the mobile phase flows out from the outlet, the two-phase solvent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com