High-strength IGBT high-power module encapsulation silica gel and encapsulation process thereof

A module packaging, high-power technology, used in adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problem of poor weather resistance and impact resistance, inability to module compatibility and adhesion, easy water permeability and oxygen permeability, etc. problems, to achieve the effect of low water absorption and oxygen absorption, good compatibility and adhesion strength, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

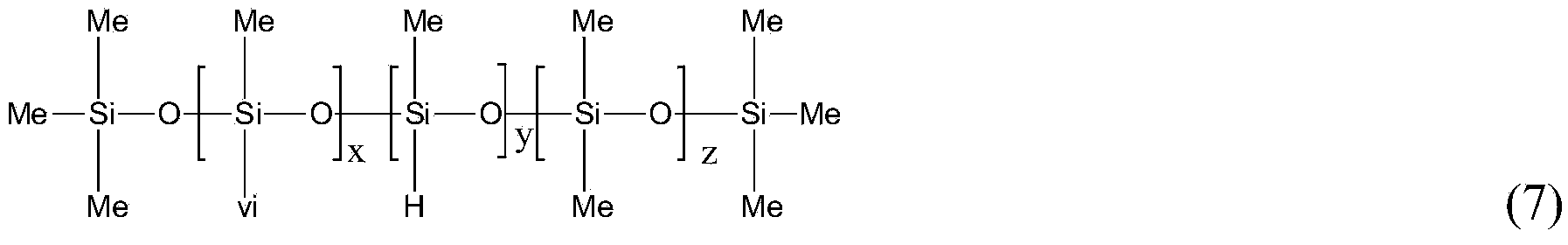

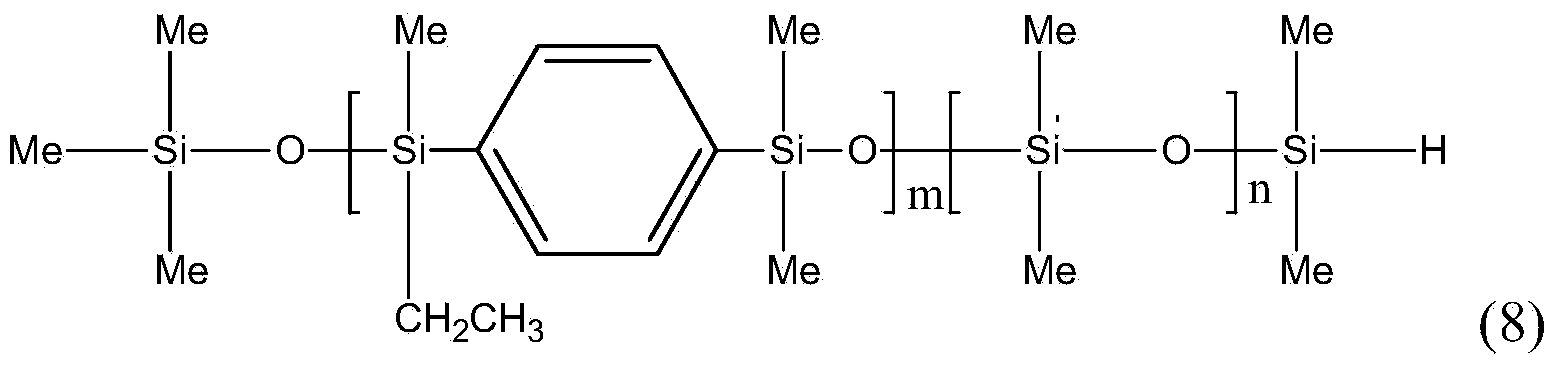

[0066] Preparation of component A: at room temperature, weigh methyl vinyl polysiloxane resin such as structural formula (1), wherein, a=0.6, b=1.2, take 40 parts; methyl vinyl silicone oil such as structural formula (3) , wherein e=50, get 50 parts; impact modifier, such as structural formula (7), wherein, x=5, y=5, z=10, get 5 parts; weather resistance agent, such as structural formula (8), wherein, m=4, n=8, get 1 part; adhesion agent, such as structural formula (9), wherein, h=5, get 3 parts; catalyst, platinum-methyl vinyl polysiloxane complex, platinum content It is 3000ppm, take 1 portion, add it to the planetary high-speed disperser one by one, stir thoroughly for 2 hours, mix evenly, vacuumize, fill and seal and store.

[0067] Preparation of component B: at room temperature, weigh methyl vinyl polysiloxane resin such as structural formula (2), wherein, c=0.7, d=1.3, take 50 parts; methyl vinyl silicone oil such as structural formula (4) f=30, g=60, take 30 parts; cr...

Embodiment 2

[0070] Preparation of component A: at room temperature, weigh methyl vinyl polyoxane resin such as structural formula (2), wherein, c=1.2, d=0.4, take 50 parts; methyl vinyl silicone oil such as structural formula (4), Wherein f=200, g=100, get 23 parts; Impact modifier, such as structural formula (7), wherein, x=20, y=20, z=50, get 15 parts; Weather resistance agent, such as structural formula (8) , wherein, m=10, n=20, get 5 parts; adhesion agent, such as structural formula (9) wherein, h=20, get 6 parts; Catalyst, platinum-methyl vinyl polysiloxane complex, The platinum content is 7000ppm, take 0.1 part, add it to the planetary high-speed disperser in turn, stir thoroughly for 2 hours, mix evenly, vacuumize, fill and seal and store.

[0071] Preparation of component B: at room temperature, weigh methyl vinyl polysiloxane resin such as structural formula (1), wherein, a=1.2, b=0.6, take 30 parts; methyl vinyl silicone oil such as structural formula (3) Wherein e=200, take 5...

Embodiment 3

[0074] Preparation of component A: at room temperature, weigh methyl vinyl polyoxane resin such as structural formula (1), wherein, a=1.0, b=0.8, take 45 parts; methyl vinyl silicone oil such as structural formula (3), Wherein e=100, get 40 parts; Impact modifier, such as structural formula (7), wherein, x=12, y=14, z=22, get 10 parts; Weather resistance agent, such as structural formula (8), wherein, m =8, n=12, get 3 parts; Adhesion force agent, such as structural formula (9), wherein, h=10, get 5 parts; Catalyst, platinum-methylvinylpolysiloxane complex, platinum content is 5000ppm, take 0.5 parts, add to the planetary high-speed disperser one by one, stir thoroughly for 2 hours, mix evenly, vacuumize, fill and seal and store.

[0075] Preparation of component B: at room temperature, weigh 20 parts of methyl vinyl polysiloxane resin as shown in structural formula (1), wherein, a=1.0, b=0.8; weigh as shown in structural formula (2) 20 parts of methyl vinyl polysiloxane resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com