Preparation method and application of asphalt modifier for roads

An asphalt modifier and road technology, applied in building components, building insulation materials, buildings, etc., can solve problems such as the inability to form a network structure, the compatibility of rubber powder and asphalt, etc. Social and economic benefits, stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

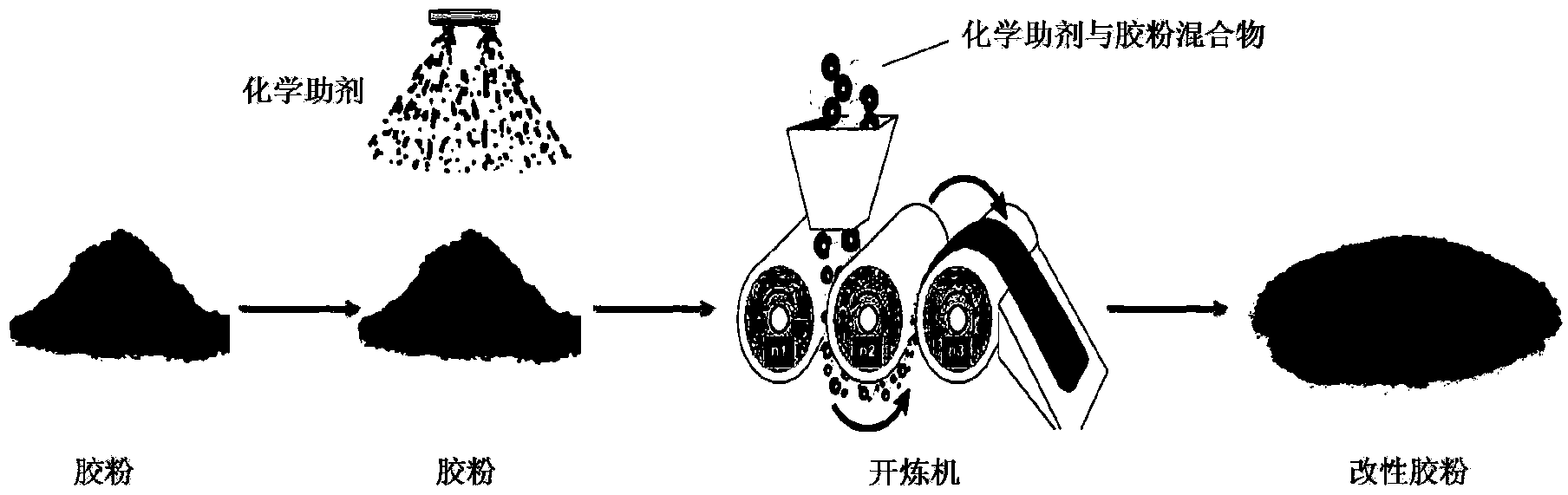

Method used

Image

Examples

Embodiment 1

[0017] Mix equal amounts of 1,1-dimethoxymethane and petroleum ether with 60-mesh rubber powder at a mass ratio of 1:20, then add the mixed rubber powder into the open mill, After repeated grinding for 6-8 minutes, the modified rubber powder can be obtained, which is the asphalt modifier for roads.

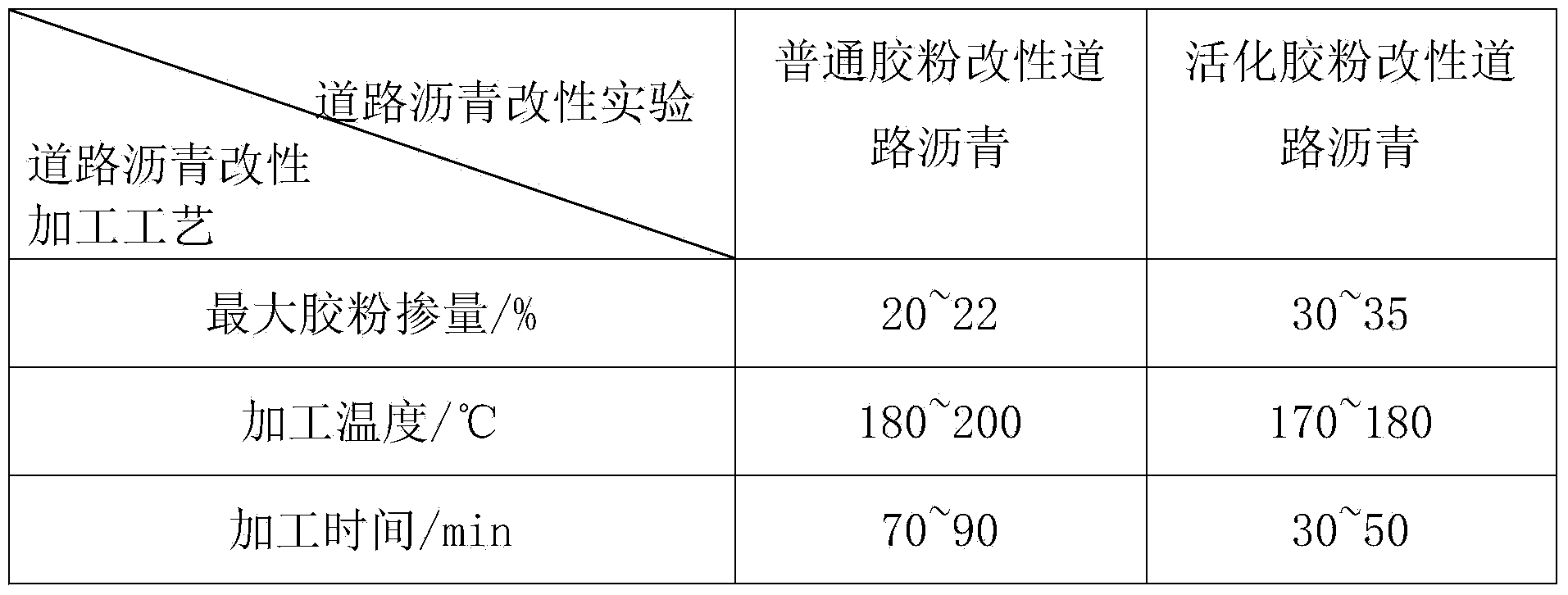

[0018] Application of asphalt modifier for roads: Add modified rubber powder to the molten asphalt system (modified rubber powder / base asphalt / SBS=3 / 6 / 1) for mixing and stirring, control the processing temperature at about 175°C, and At a speed of 3500rpm / min, mix and stir for 40 minutes to obtain a high-grade road modified asphalt mixture.

[0019] The above are only preferred embodiments of the embodiments of the present invention, and are not intended to limit the embodiments of the present invention. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the embodiments of the present invention shall include Within the protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com